CHECK AND TEST 1

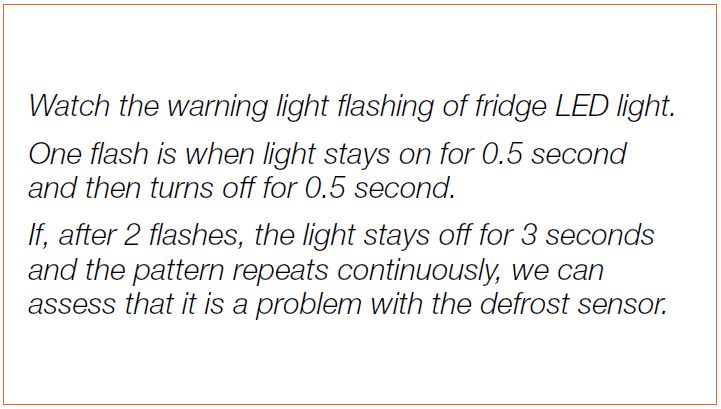

Note

Step 1

Unscrew cover of mainboard with aCross-head screwdriver.

Step 2

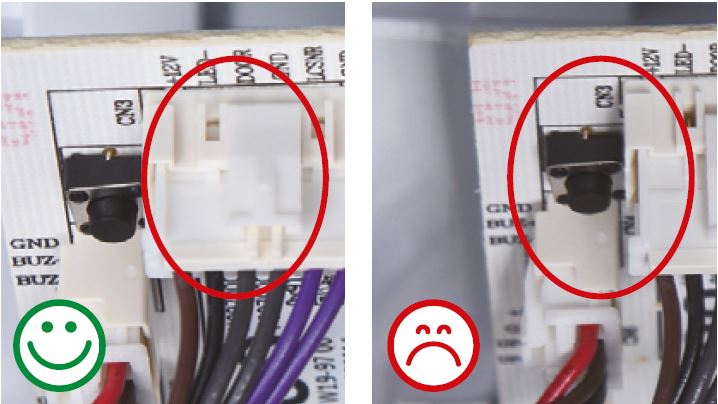

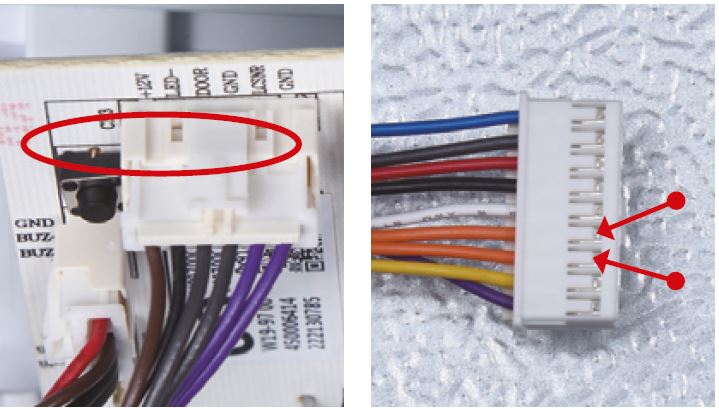

Check if terminal in PCB

area is pushed to final

position.

If not, reinsert it to final

position.

Step 3

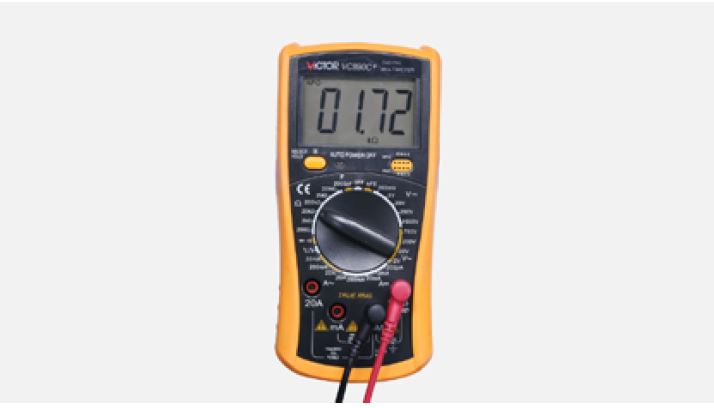

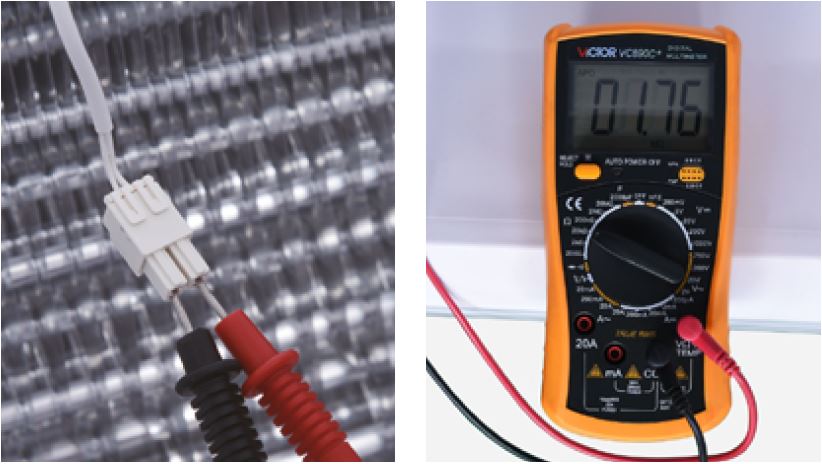

Set multimeter to

resistance gear.

Step 4

In PCB area, measure the

resistance of defrost temp.

sensor with a multimeter.

Step 5

Take note of value.

Step 6

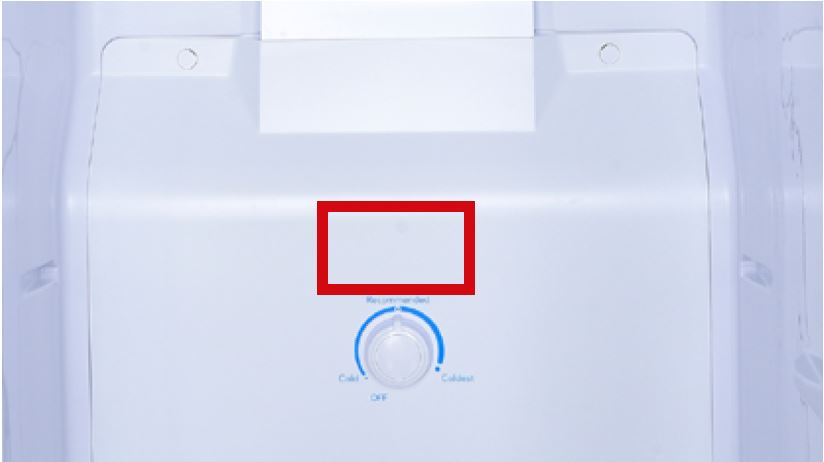

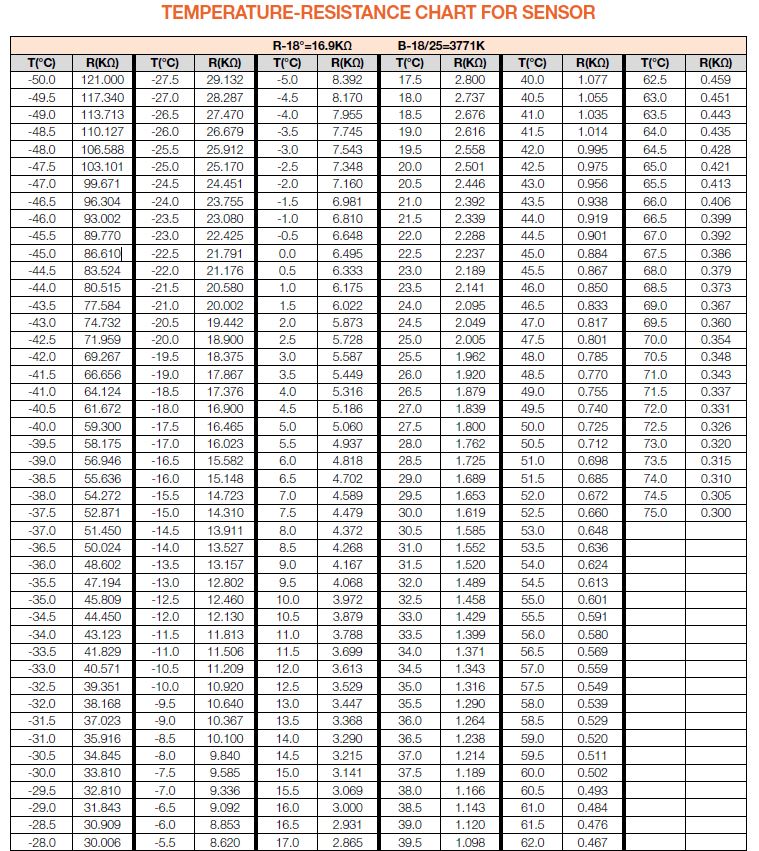

Measure the temperature

of freezer air duct, near the

defrost temp. sensor.

Use measured temperature

to find the standard

resistance value in

Temperature-Resistance

Chart for Sensor.

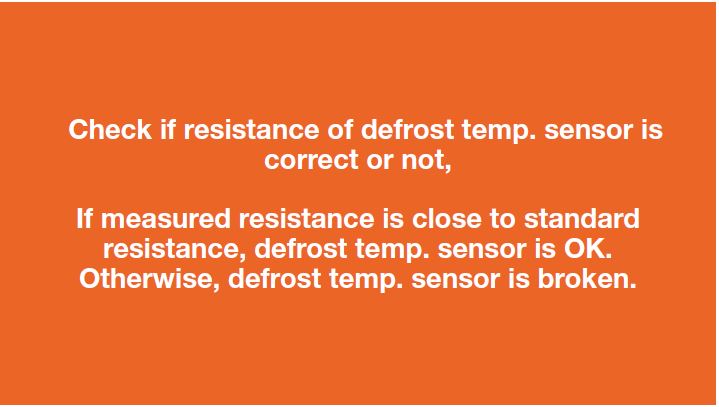

DIAGNOSIS 1

PROCEDURE 1

Step 1

Unscrew cover of

mainboard with a

Cross-head screwdriver.

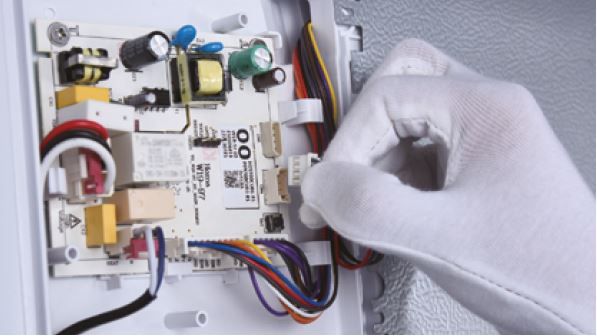

Step 2

Disconnect terminals.

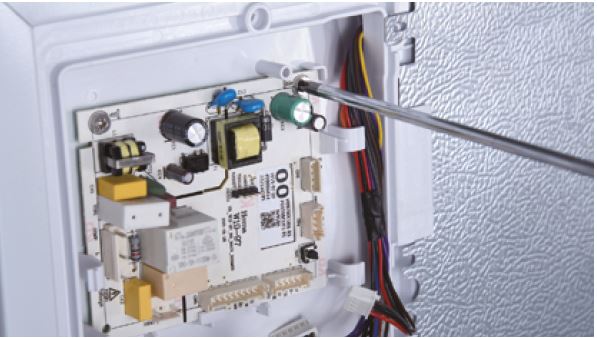

Step 3

Unscrew the mainboard.

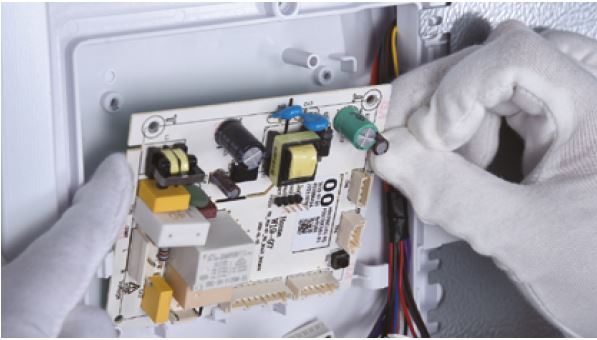

Step 4

Prize off the buckle to

remove mainboard.

Reverse steps above

to install a new

mainboard.

PROCEDURE 1

Step 1

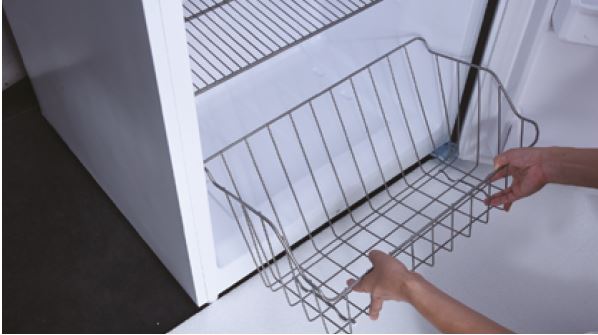

Remove all shelves.Step 2

Remove basket.

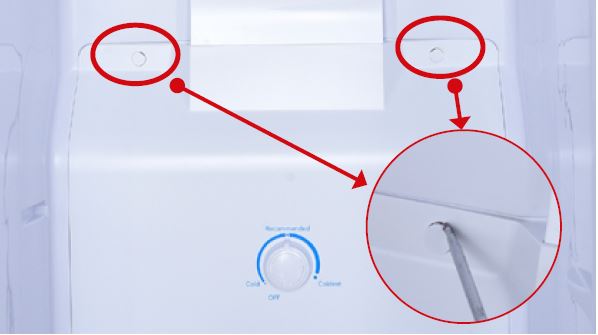

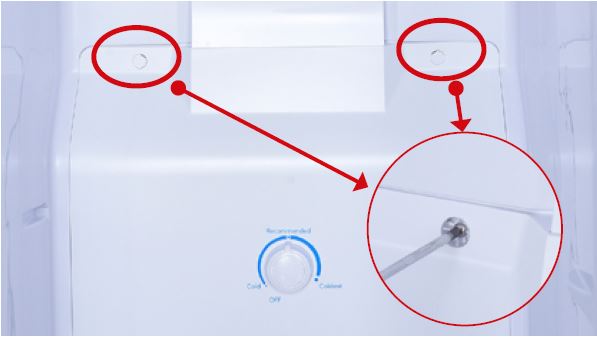

Step 3

Remove screw covers.

Step 4

Unscrew.

Step 5

Pull the buttom air duct

out.

Step 6

Disconnect the wires for

thermostat.

Step 7

Take bottom air duct

away.

CHECK AND TEST 2

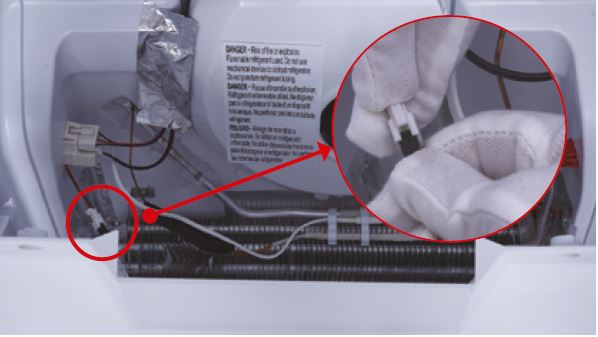

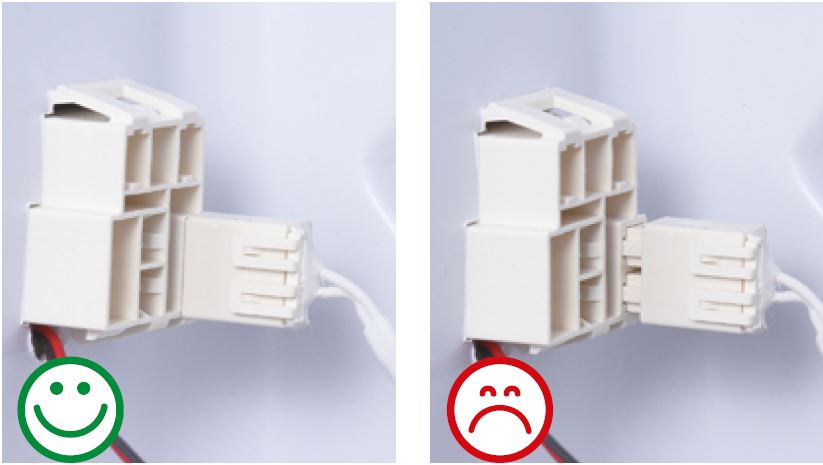

Step 1

Check if terminal is inserted to final position.

If not, please re-insert it to final position.

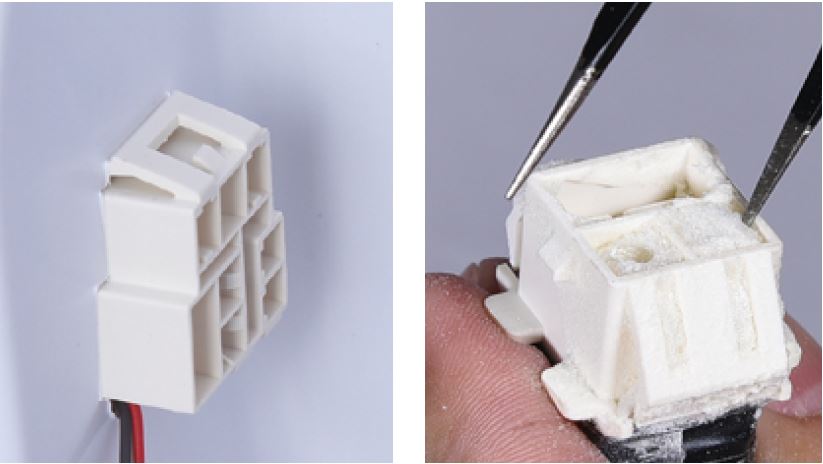

Step 2

Check if the terminal is

stuffed with foam.

IF SO, USE TWEEZERS

TO SMASH IT AND

REMOVE.

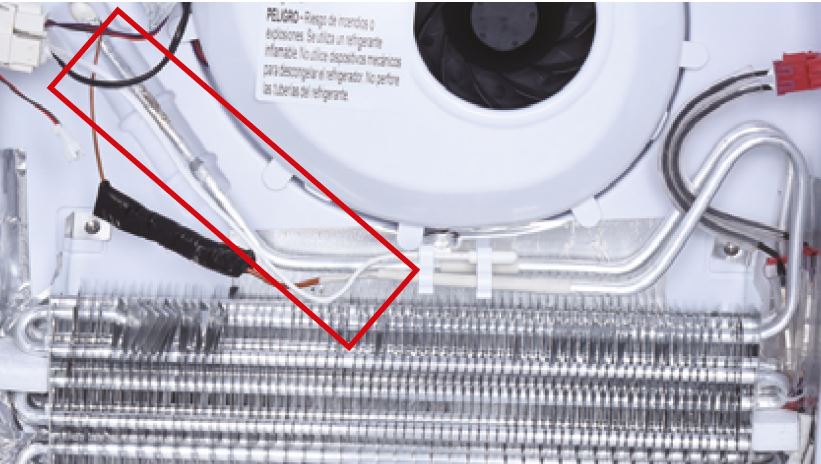

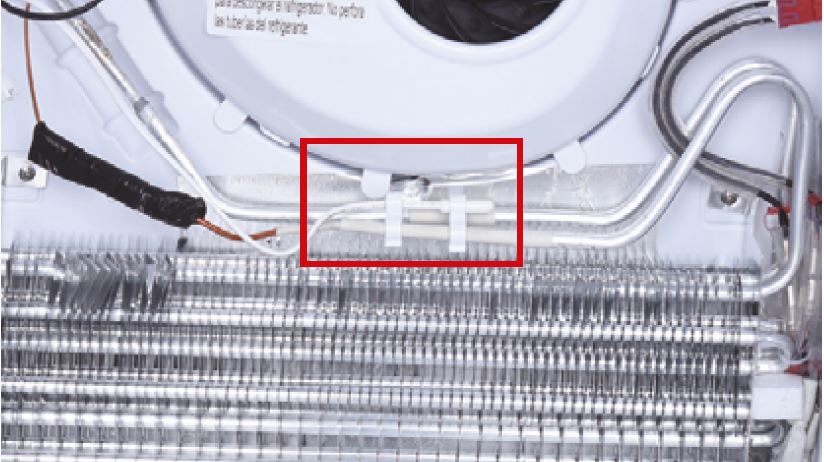

Step 3

Check if sensor is

attached in proper

position, as shown in

picture.

If not, correct it.

Step 4

Check if wire of defrost

sensor is broken.

If yes, replace it with a

new one.

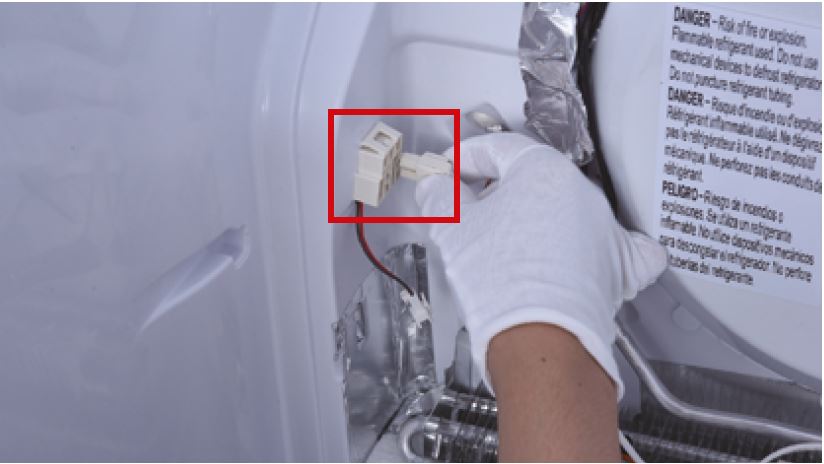

Step 5

Disconnect terminal of

defrost temp. sensor.

Step 6

Measure resistance of

defrost temp. sensor

from terminal in freezer,

and take note of it.

Step 7

Measure the temperature

of defrost temp. sensor.

Use measured

temperature to find the

standard resistance

value in Temperature-

Resistance Chart for

Sensor.

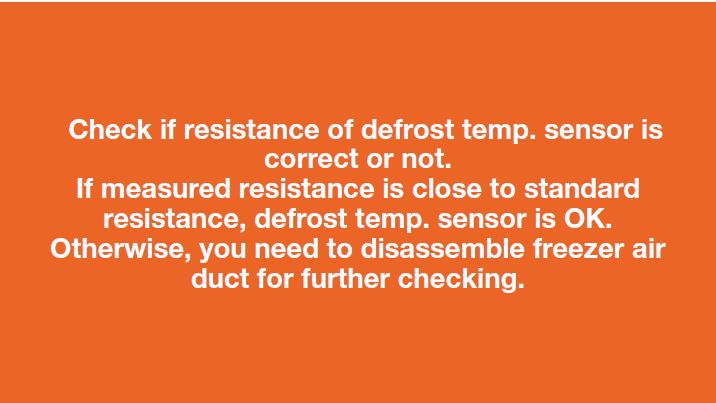

DIAGNOSIS 2

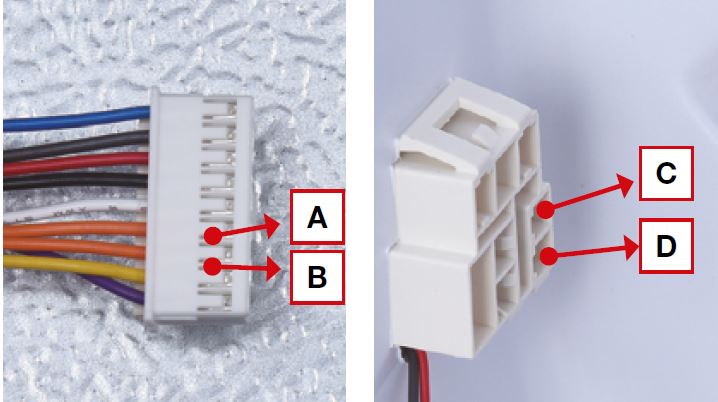

Step 2

Put detector into one

end of wires in PCB area.

Put another detector into

end of wires behind air

duct.

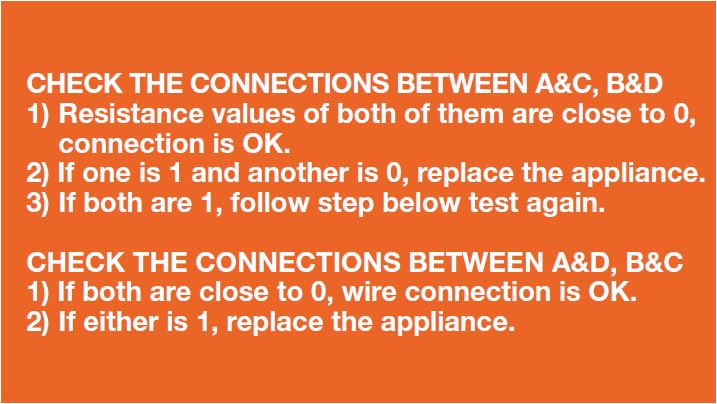

DIAGNOSIS 3

PROCEDURE 2

Tip 1

Make sure the sealing

sponges are in good

condition.

Tip 2

When reinstalling the air

duct, fasten the wires to

avoid crushing with air

duct.

Tip 3

Check to see if there is

a wide gap between air

duct and cabinet. If there

is, reinstall air duct.