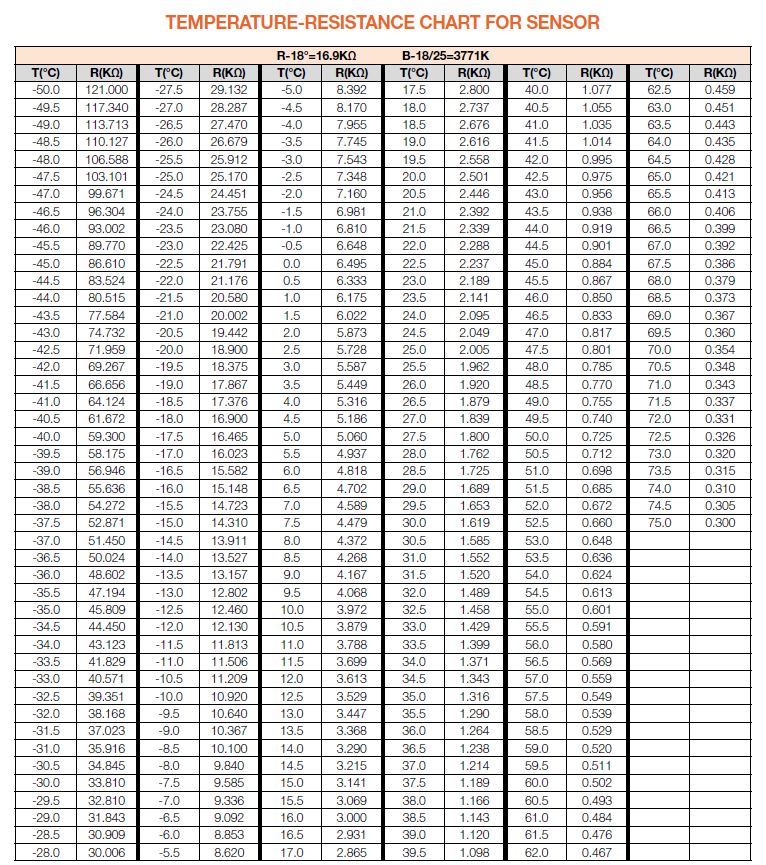

CHECK AND TEST 1

Note

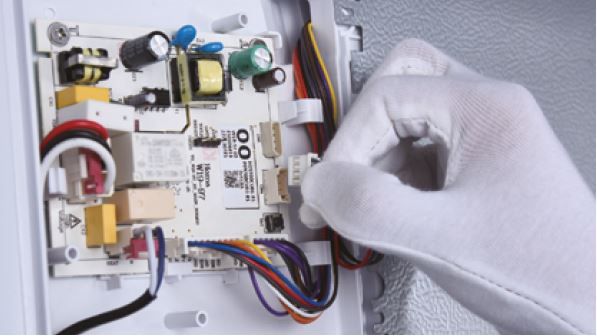

Step 1

Unscrew cover of mainboard with aCross-head screwdriver.

Step 2

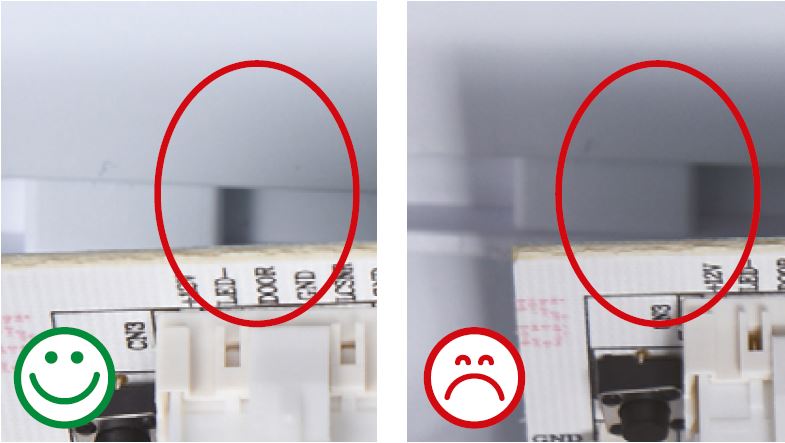

Check if terminal in PCB

area is inserted to final

position.

If not, reinsert it to final

position.

Step 3

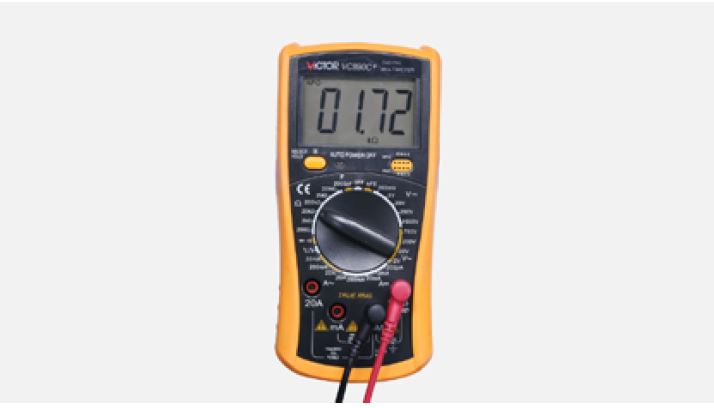

Set multimeter to

resistance gear.

Step 4

In PCB area, measure the

resistance of freezer temp.

sensor with a multimeter.

Step 5

Take note of value.

Step 6

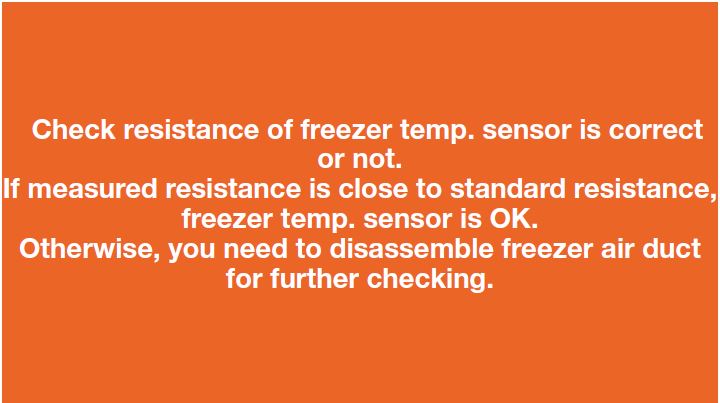

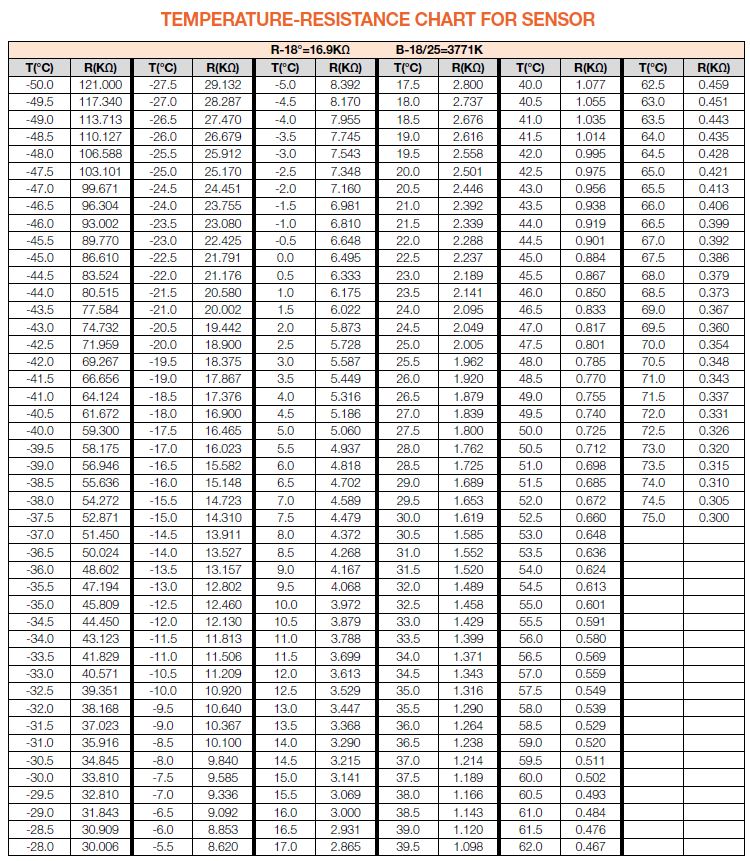

Measure temperature

of freezer temp. sensor.

Use the measured

temperature to find the

standard resistance value

in Temperature-Resistance

Chart for Sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Unscrew cover of

mainboard with a

Cross-head screwdriver.

Step 2

Disconnect terminals.

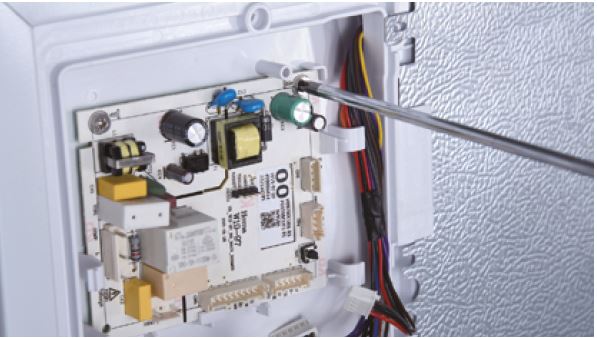

Step 3

Unscrew the mainboard.

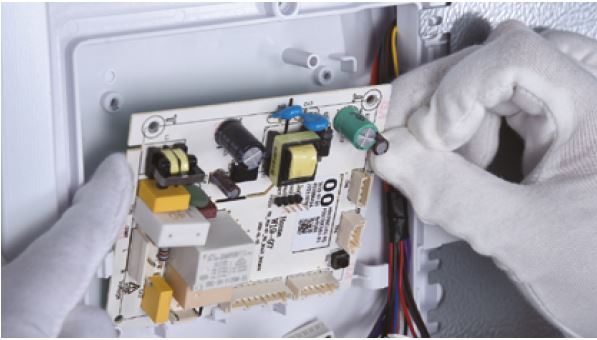

Step 4

Prize off the buckle to

remove mainboard.

Reverse steps above

to install a new

mainboard.

PROCEDURE 1

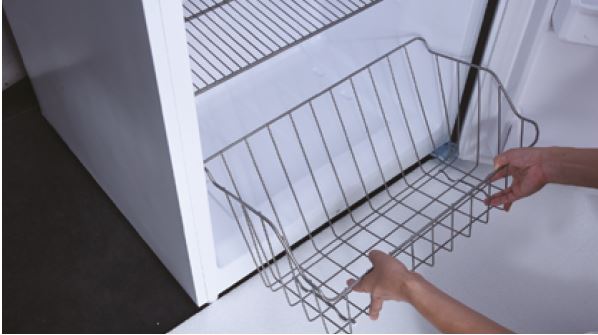

Step 1

Remove all shelves.

Step 2

Remove basket.

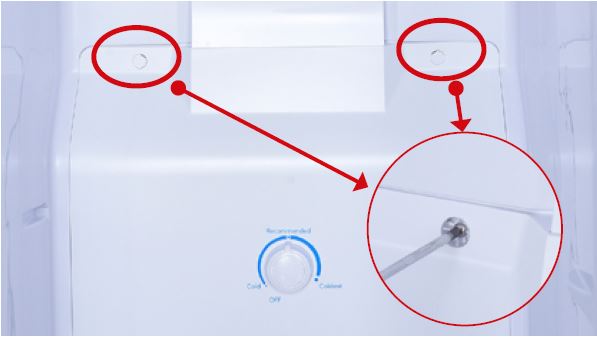

Step 3

Unscrew.

Step 5

Pull the buttom air duct

out.

Step 6

Disconnect the wires for

thermostat.

Step 7

Take bottom air duct

away.

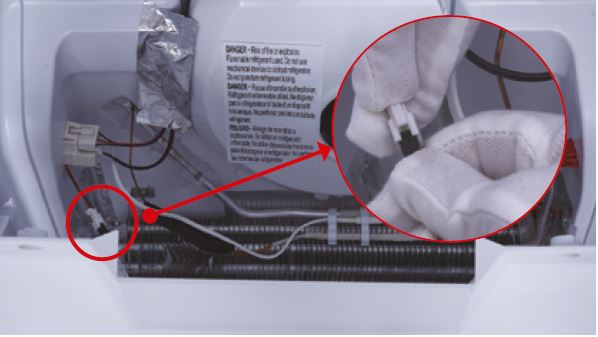

CHECK AND TEST 2

Step 1

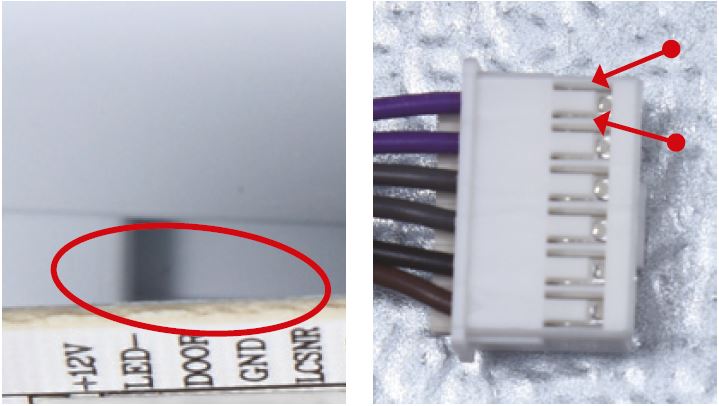

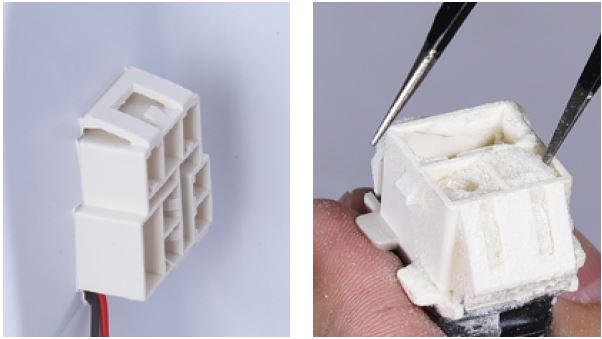

Check if the terminal

is inserted into final

position.

IF SO, RE-INSERT

THEM.

Step 2

Check if the terminal is

stuffed with foam.

IF SO, USE TWEEZERS

TO SMASH IT AND

REMOVE.

Step 3

Measure resistance of

freezer temp. sensor from

terminal in freezer air duct

cover.

Step 4

Measure temperature

of freezer temp. sensor.

Use the measured

temperature to find the

standard resistance

value in Temperature-

Resistance Chart for

Sensor.

DIAGNOSIS 2

PROCEDURE 2

Step 1

Disconnect terminals.

Step 2

Remove the aluminium

tape.

Step 3

Unscrew.

Step 4

Use slot screw driver to

push the buckle into,

then pull the upper air

duct out and take it

away.

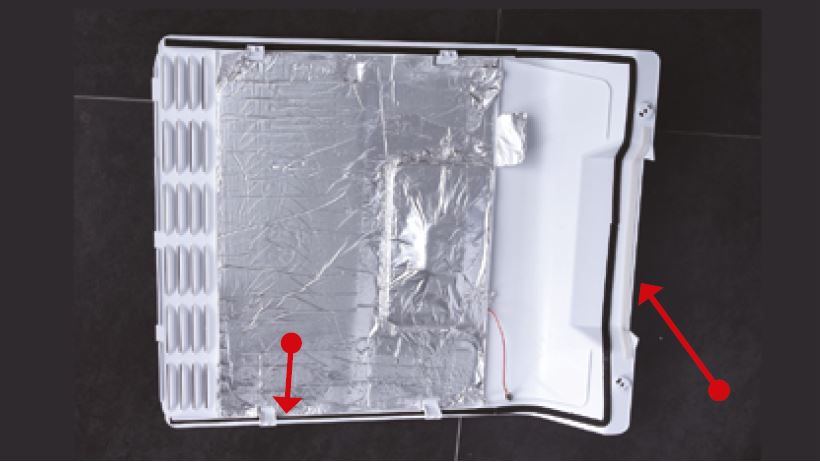

PROCEDURE 3

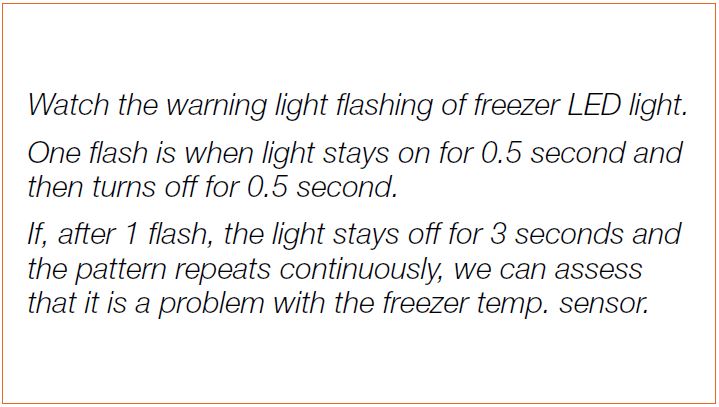

Note

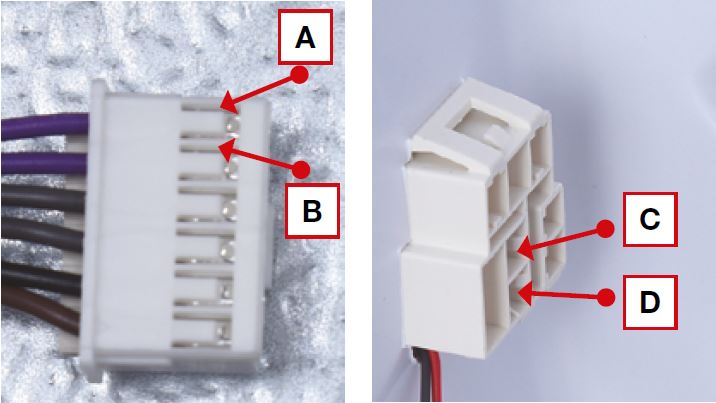

CHECK AND TEST 3

Step 1

Set multimeter toresistance gear.

Step 2

Put detector into one

end of wires in PCB area.

Put another detector into

end of wires behind air

duct.

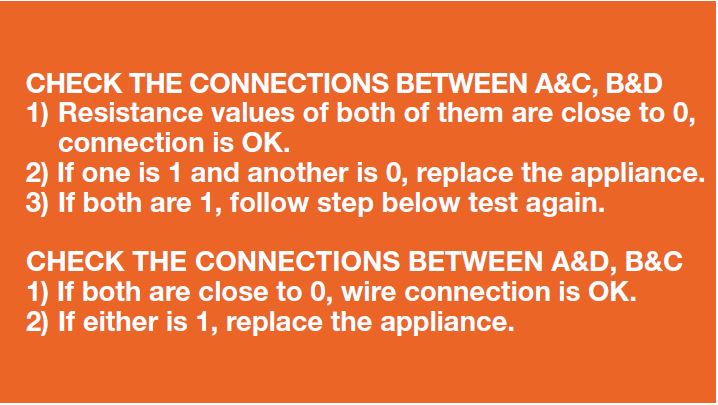

DIAGNOSIS 3

PROCEDURE 2

Tip 1

Make sure the sealing

sponges are in good

condition.

Tip 2

When reinstalling the air

duct, fasten the wires to

avoid crushing with air

duct.

Tip 3

Check to see if there is

a wide gap between air

duct and cabinet. If there

is, reinstall air duct.

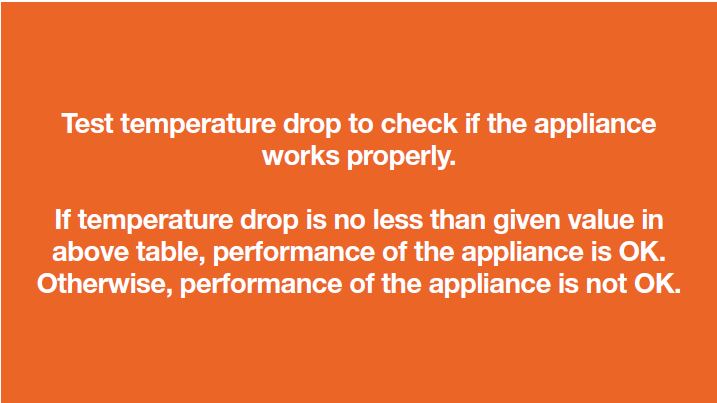

CHECK AND TEST 4