CHECK AND TEST 1

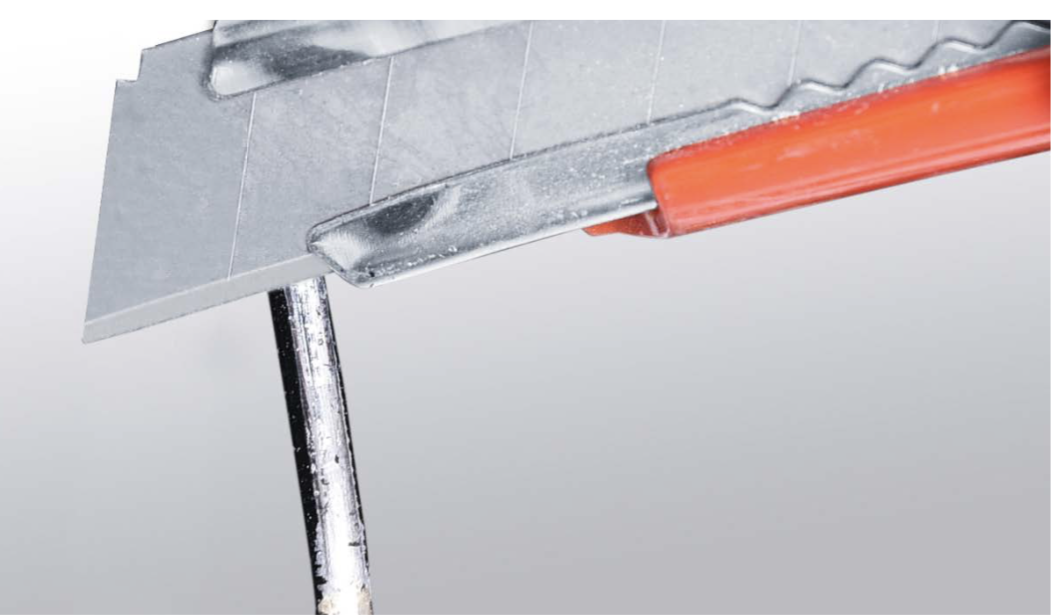

Step 1

Discharge refrigerant.Cut off the charging tube with pliers.

Step 2

Release all refrigerant toward the exhaust vent.

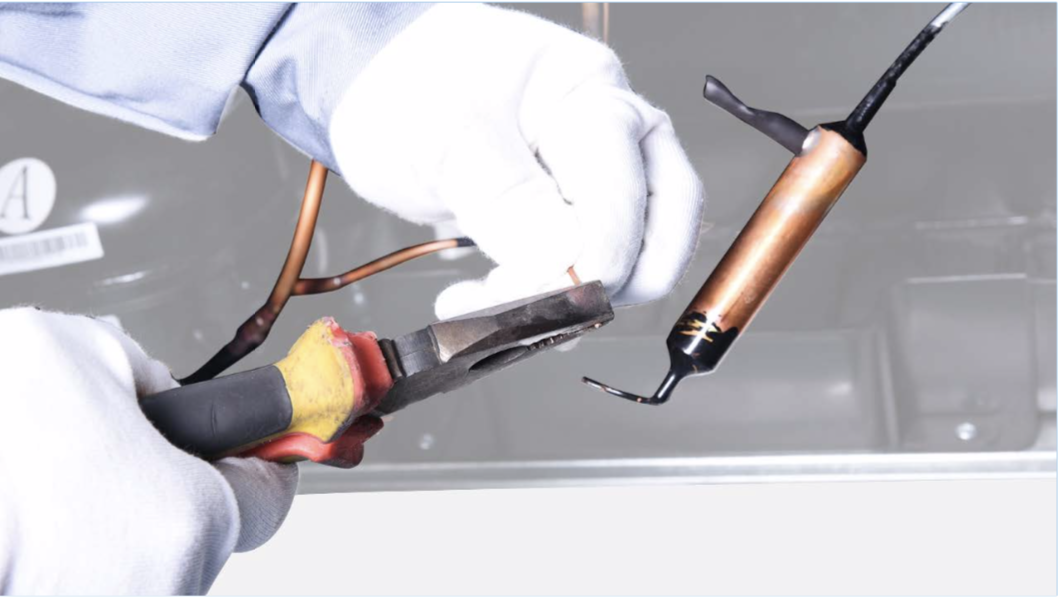

Step 3

Melt brazing material with flame and pull processing tube out using a pair of pliers.

Step 4

Re-braze a copper tube onto processing tube of compressor.Please find more details of brazing requirements go to

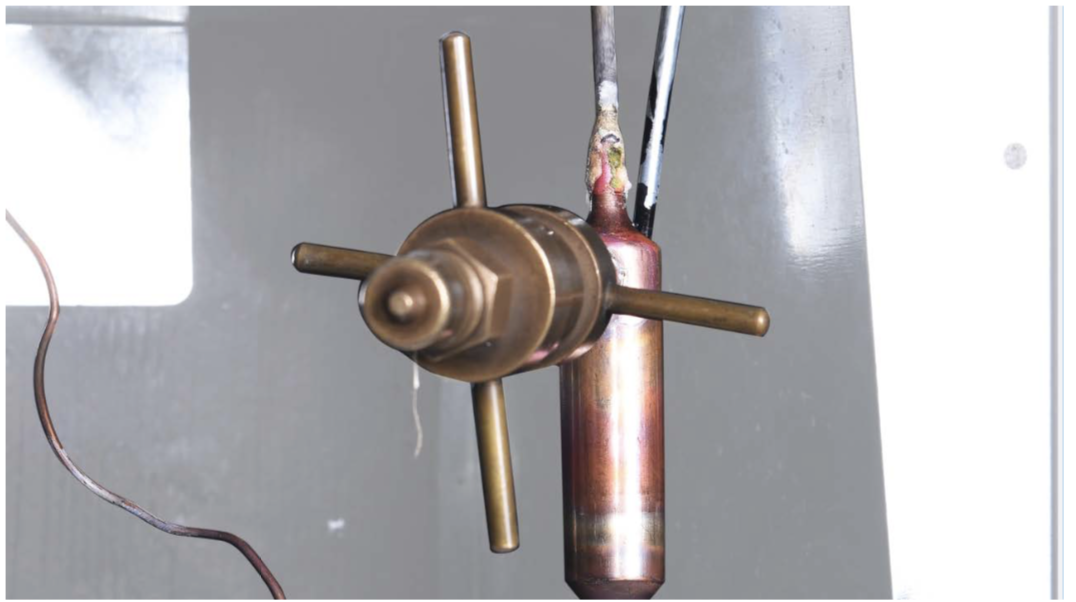

Step 5

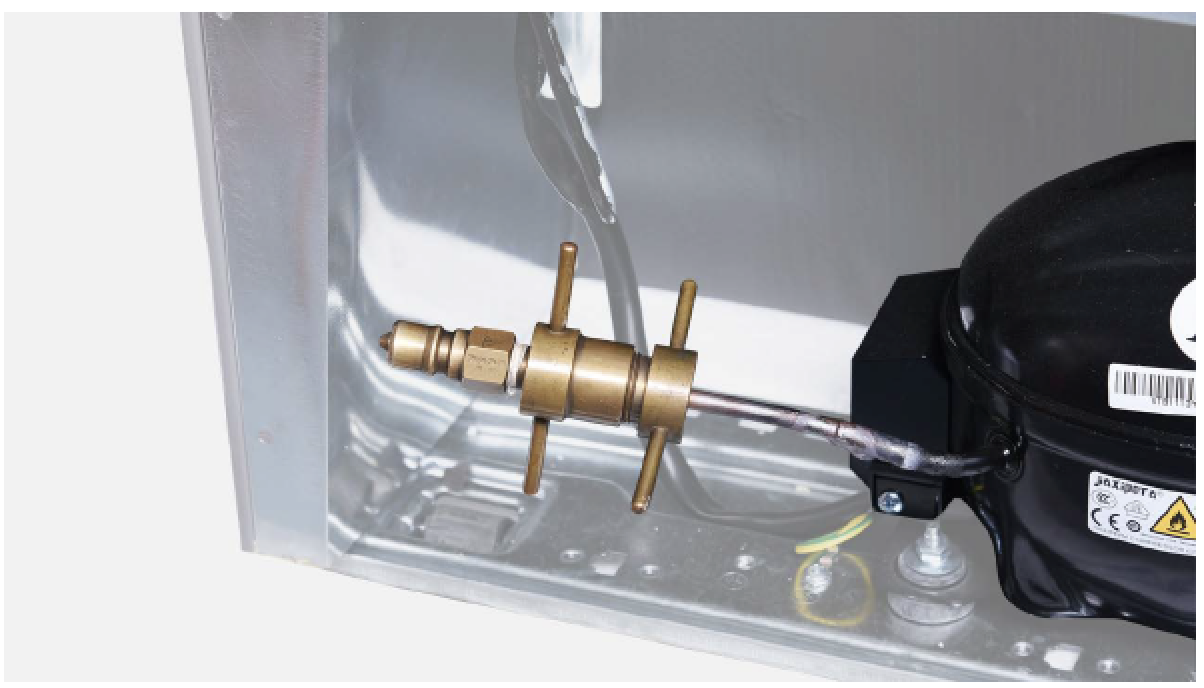

Install quick connector onto re-brazed pipe.

Step 6

Use pliers to cut the capillary off.

Step 7

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow left refrigerant away.

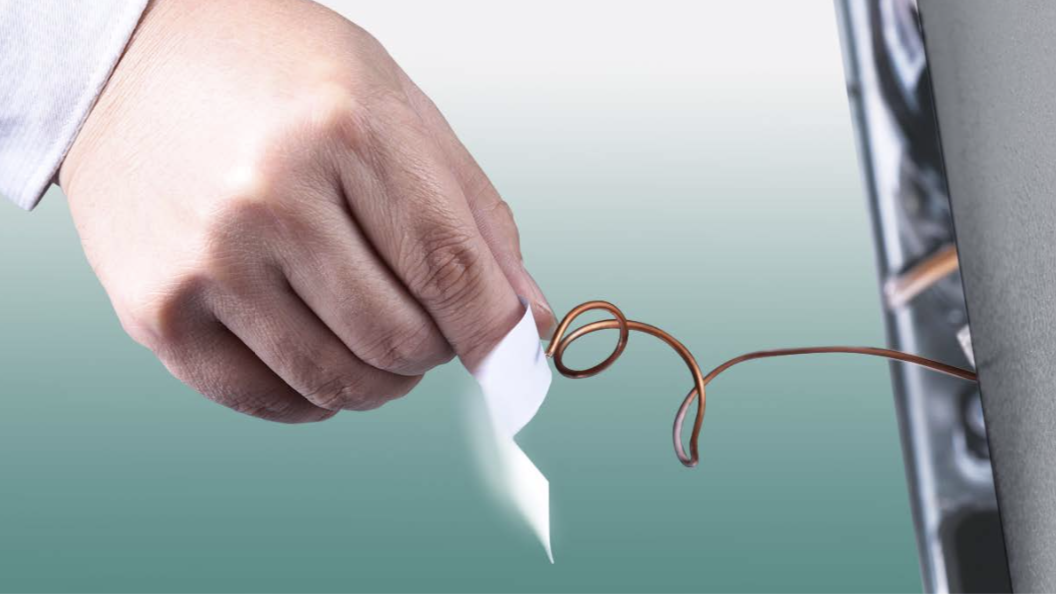

Step 8

Check whether oil is being ejected from the capillary using a piece of white paper.

Step 9

Cut off exhaust pipe to check whether oil is being ejected from compressor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover

Step 3

Remove protector and starter.

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut for compressor.

Step 6

testo testo

PROCEDURE 2

Step 1

Re-braze a copper tube onto processing tube for compressor.

To get more details on brazing requirements, please go to

NOTE

Step 2

Weld the joints of suction and exhaust pipes.

PROCEDURE 3

Step 1

Clean paint off brazed joint of drying-filter

Step 2

testo testo

Step 3

Cut off capillary and shake to remove the cut end.

Step 4

Weld on a new drying- filter.

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Perform leakage test on brazed joints of drying- filter and compressor processing pipe.

Step 8

Vacuum and recharge.

Please get more details

of vacuuming and gas-

charging requirements go to

Step 9

Block processing pipe twice with locking pliers.

Step 10

Leave locking pliers on the second block and cut off the rest of the pipe by shaking.

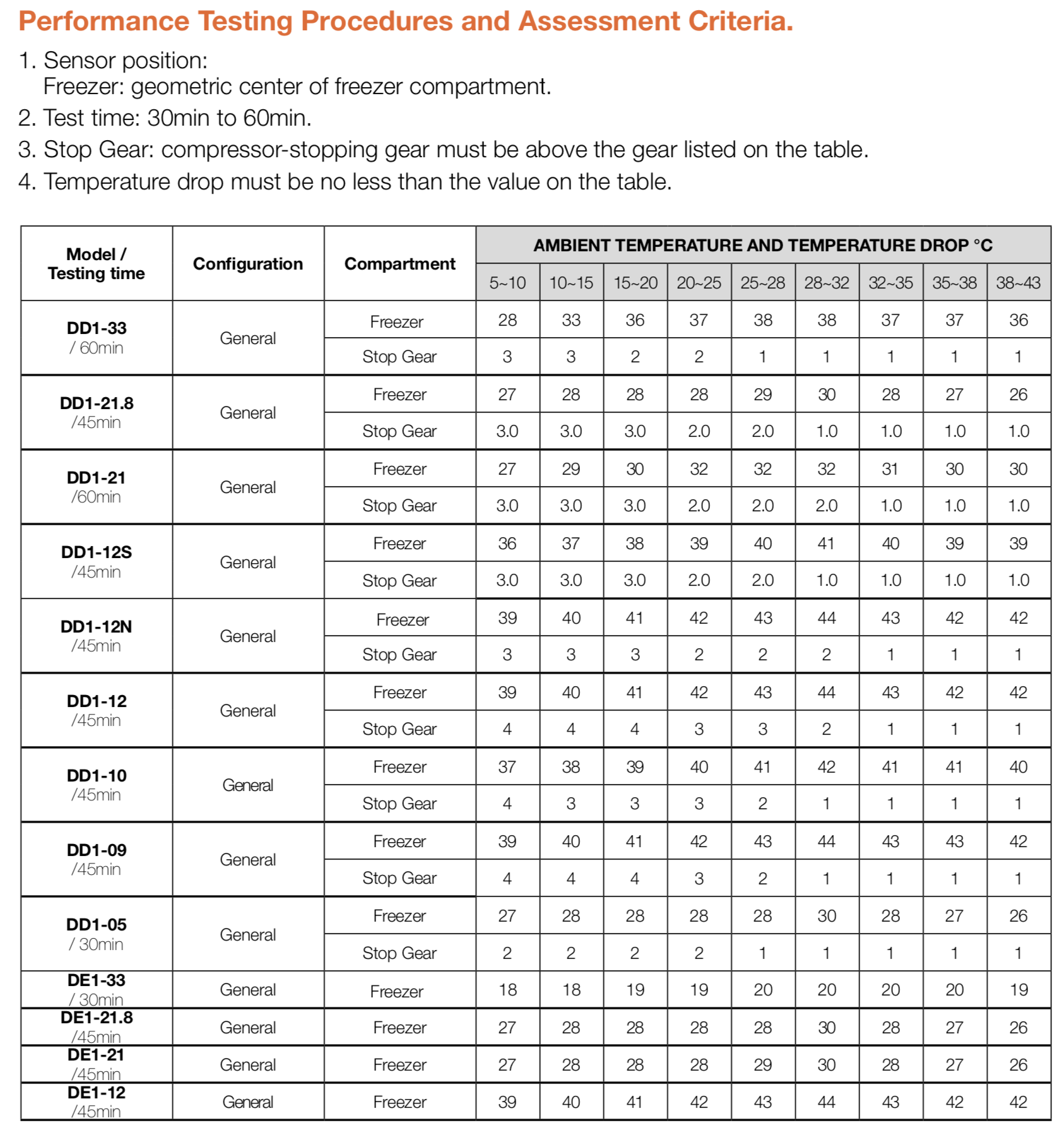

CHECK AND TEST 2

DIAGNOSIS 2