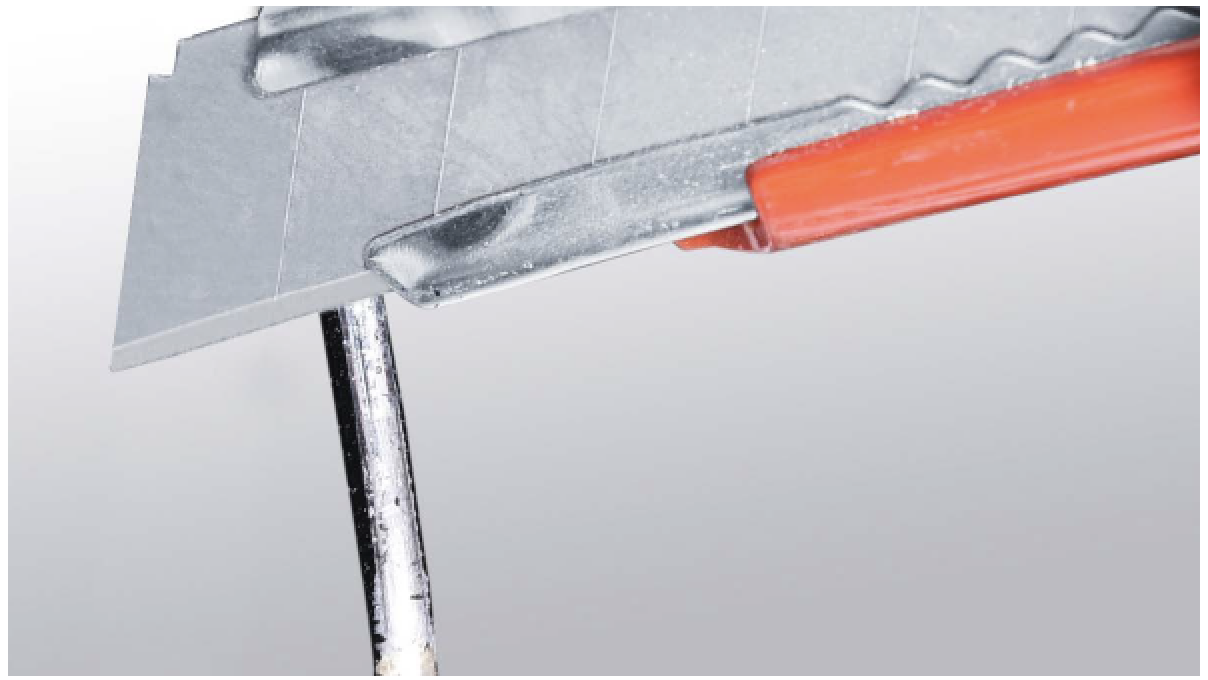

Step 1

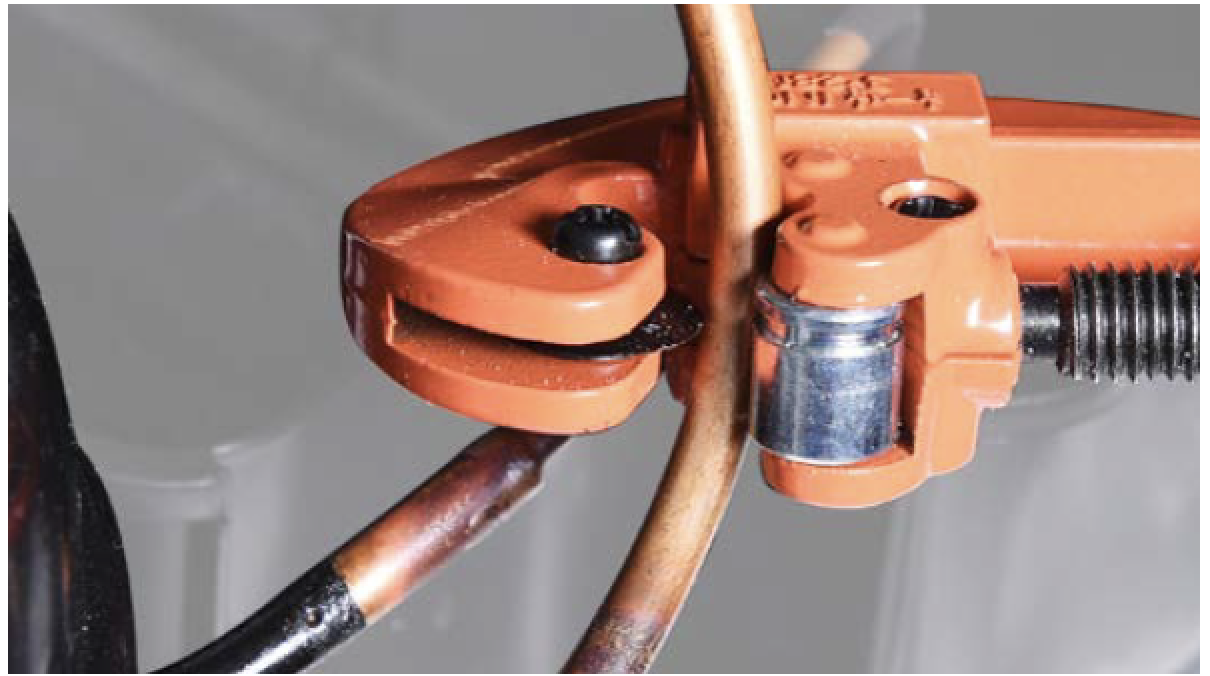

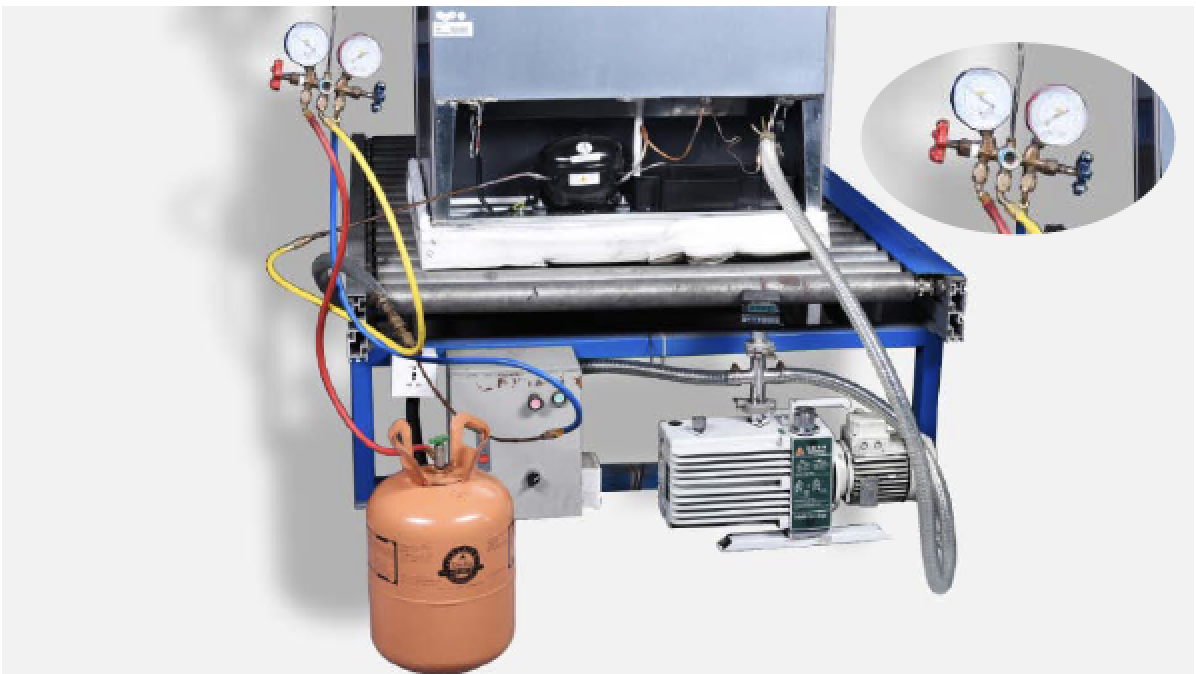

Discharge refrigerant: use pliers to cut off charging tube.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Melt brazing material with flame and pull processing tube out using a pair of pliers.

Step 4

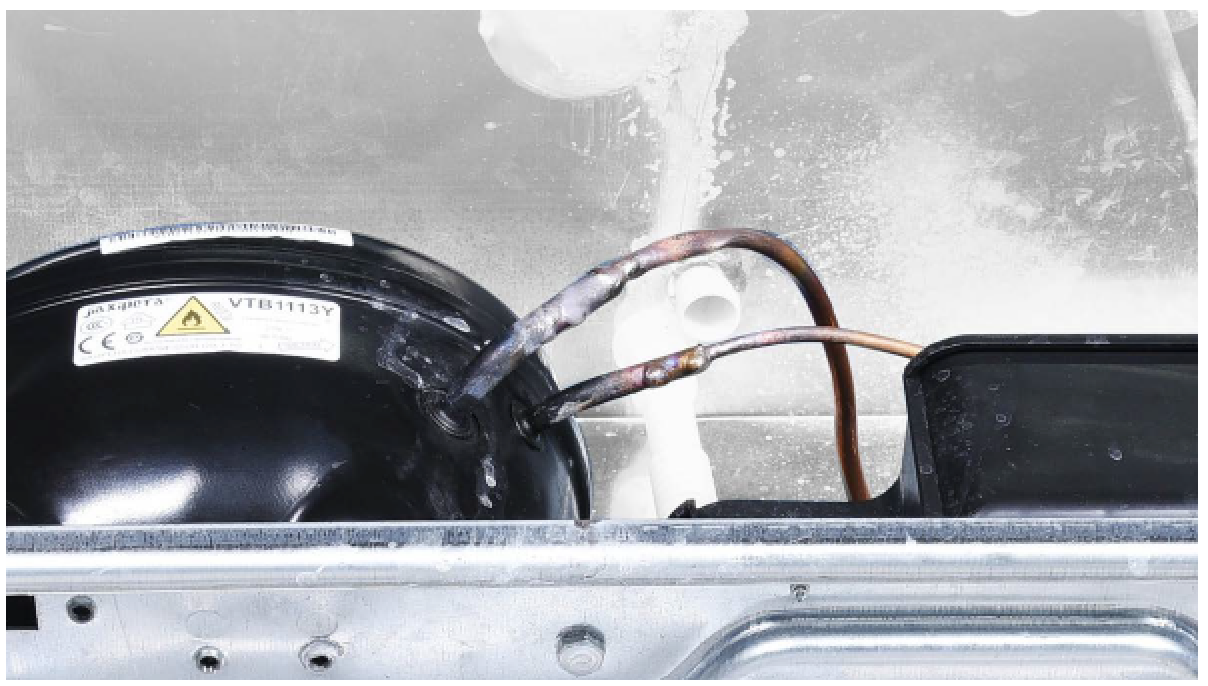

Re-braze a copper tube onto processing tube of compressor.To get more details on brazing requirements, please go to

NOTE

Step 5

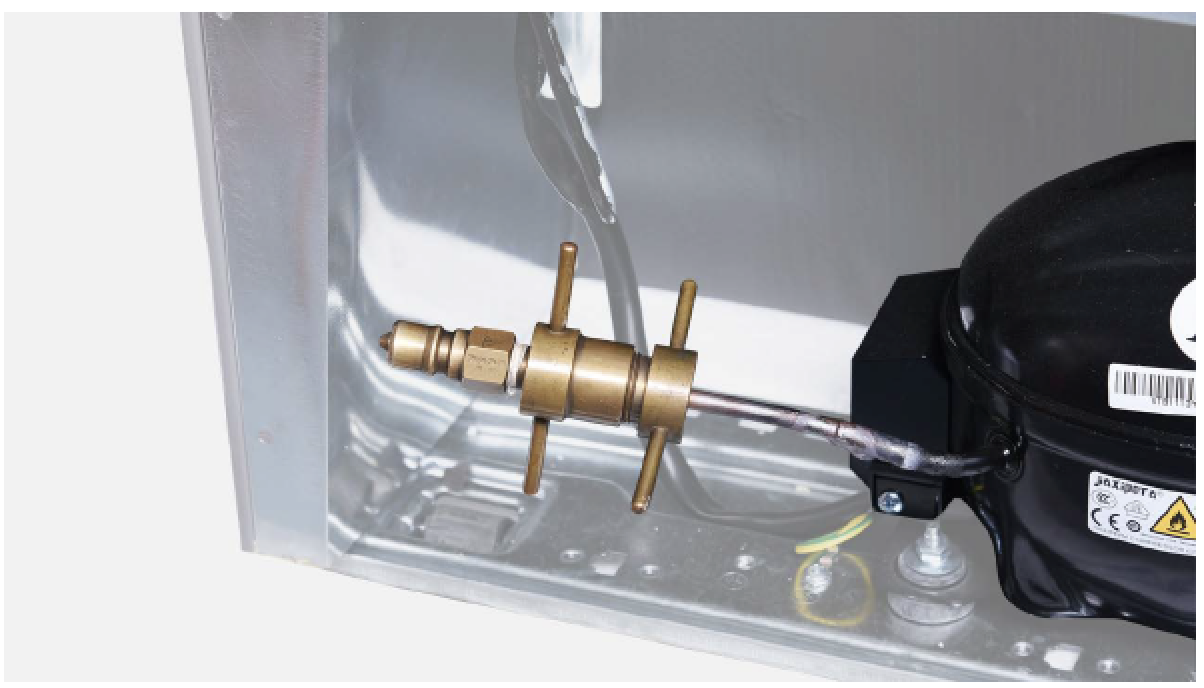

Install quick connector onto re-brazed pipe.

Step 6

Cut off suction pipe and exhaust pipe.

Step 7

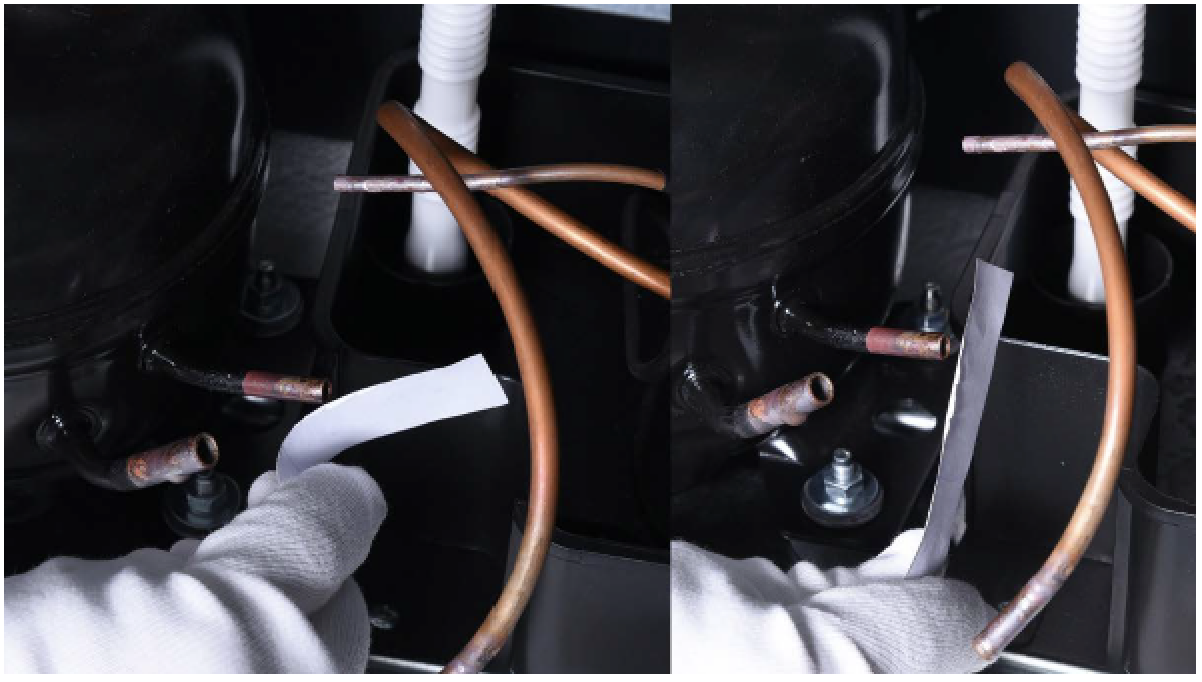

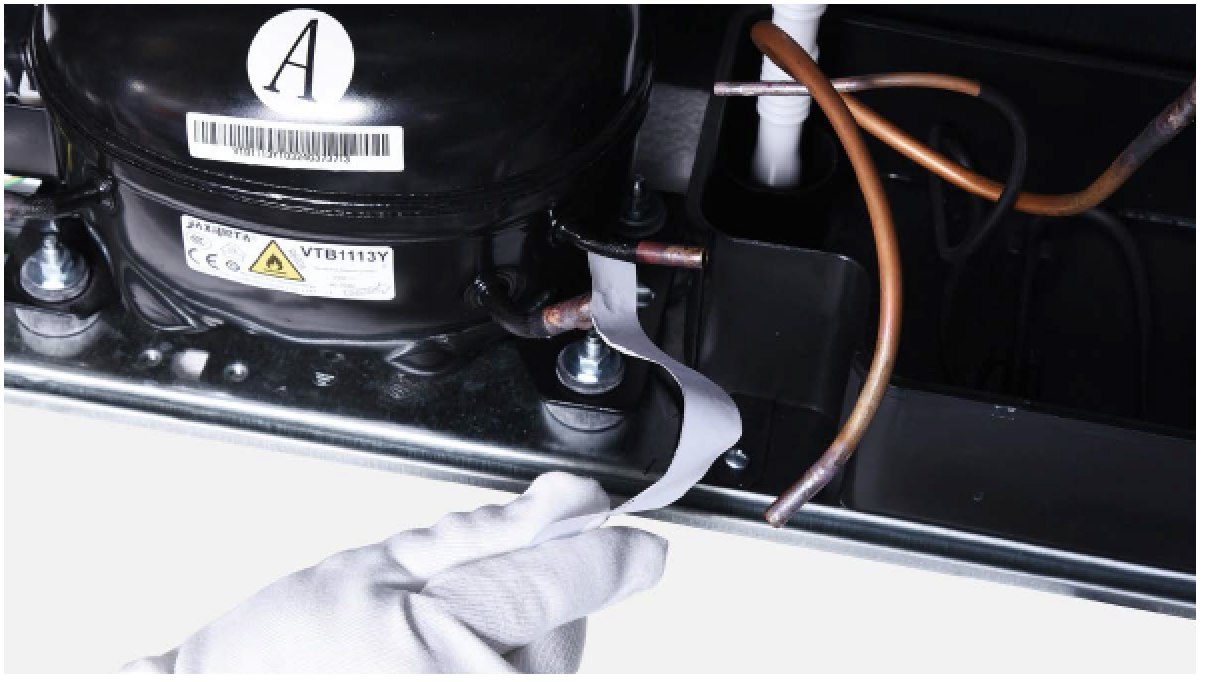

Power up the compressor and feel theexhaust pressure from the exhaust pipe with a

piece of paper.

Step 8

Feel the suction pressure of the suction pipe using a piece of paper.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover

Step 3

Remove protector and starter.

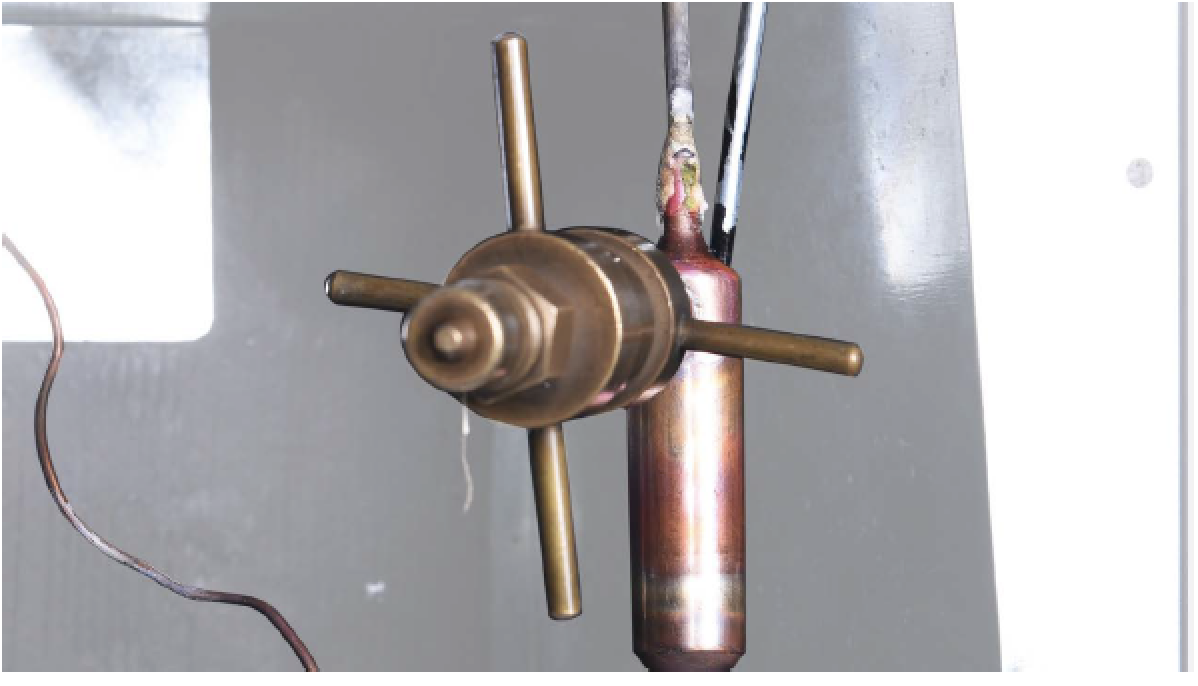

Step 1

Re-braze a copper tube onto processing tube for compressor.To get more details on

brazing requirements,

please Annex B1

NOTE

Step 2

Weld the joints of suction and exhaust pipes.

PROCEDURE 3

Step 1

Clean paint off brazed joint of drying-filter

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and shake to remove the cutend.

Step 4

Weld on a new dryingfilter.

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe ofdrying-filter.

Step 7

Perform leakage test on brazed joints of dryingfilter and compressor processing pipe.

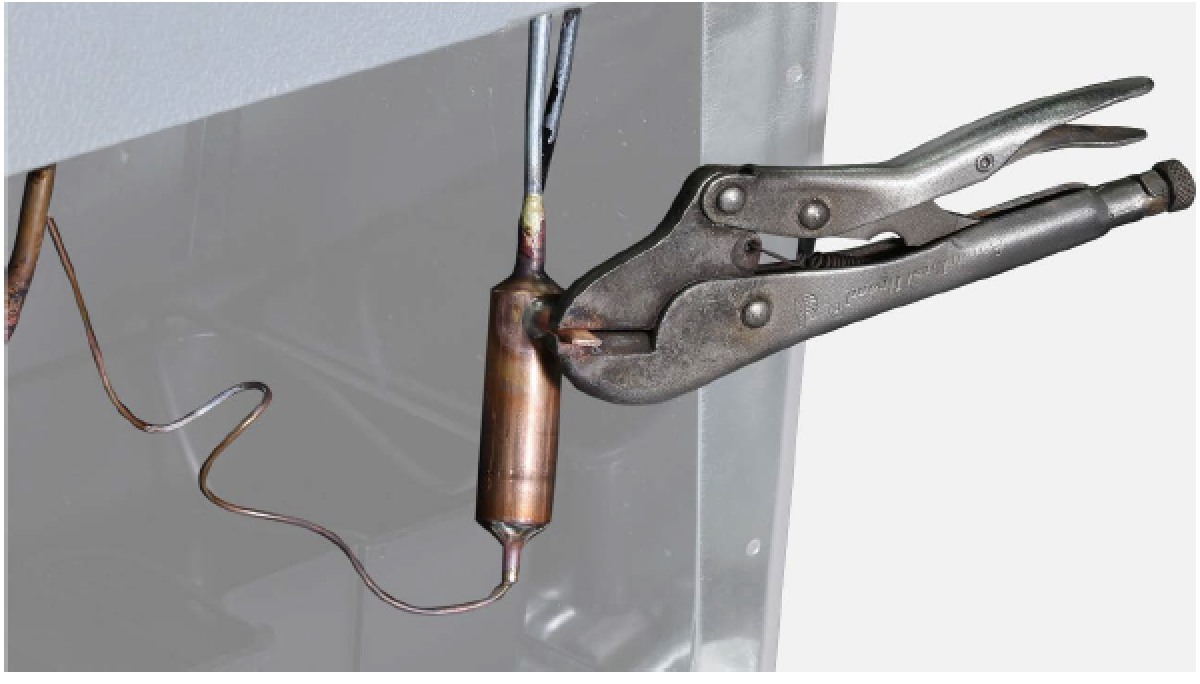

Step 9

Block processing pipe twice with locking pliers.

Step 10

Leave locking pliers on the second block andcut off the rest of the pipe by shaking.

Step 11

Weld the ends and remove the pliers.

CHECK AND TEST 2

DIAGNOSIS 2

Attention