CHECK AND TEST 1

Step 1

Put your hand on

compressor and feel the

vibration.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Discharge refrigerant.

Cut charging tube off with pliers.

Step 2

Discharge all refrigerant

toward the exhaust vent.

Step 3

Cut off suction pipe and

exhaust pipe.

Step 4

Unscrew terminal cover.

Step 5

Remove terminal cover.

Step 6

Remove protector and starter.

Step 7

Unscrew earthing wire.

Step 8

Unscrew nut on compressor.

Step 9

Install a new compressor and tighten the nuts onto compressor.

Step 10

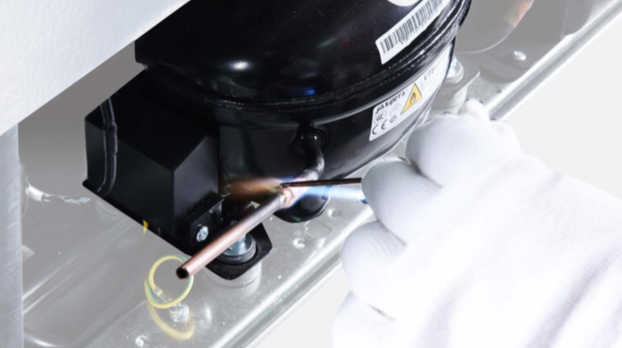

Braze the joints of suction and exhaust pipes.

Step 11

Re-braze a copper tube onto compressor processing tube.

Step 12

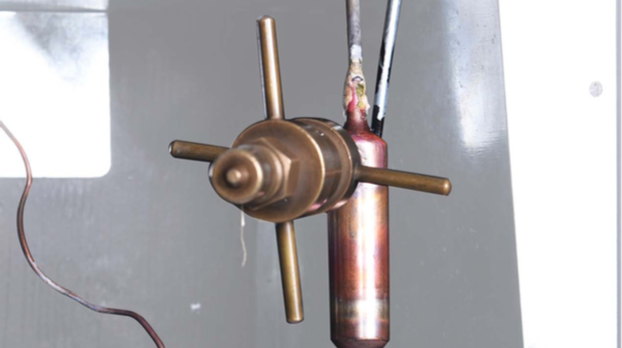

Install quick connector onto re-brazed pipe.

Step 13

Melt brazing material with flame and pull out processing tube with pliers.

Step 14

Re-braze a copper tube onto compressor processing tube.

Step 15

Clean paint off brazed joint of drying-filter.

Step 16

Cut off drying-filter.

Step 17

Cut off capillary and remove the cut end by shaking.

Step 18

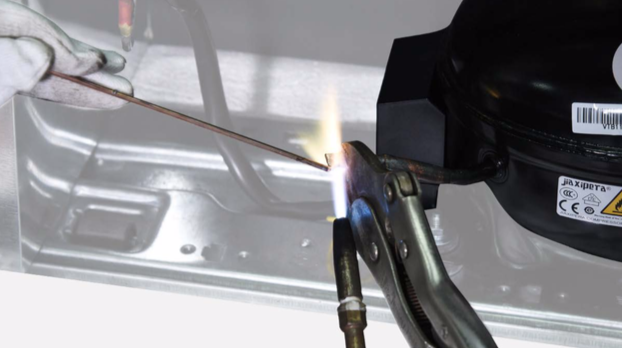

Weld on a new drying-filter.

Step 19

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 20

Add quick connector onto processing pipe of drying-filter.

Step 21

Perform leakage test on brazed joints of drying- filter and compressor processing pipe.

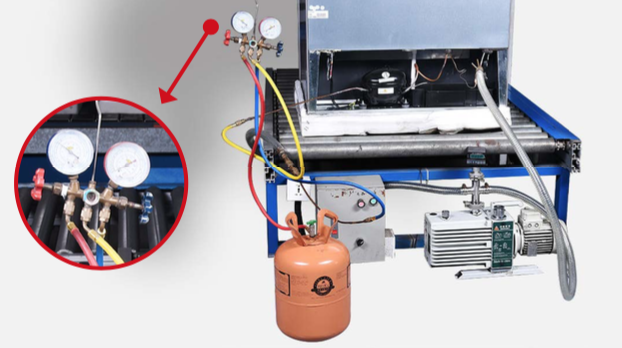

Step 22

Vacuum and recharge.

Please get more details of vacuuming and gas- charging requirements on page 313

Step 23

Block processing pipe twice with locking pliers.

Step 24

Leave locking pliers on the second block and cut off the rest of the pipe by shaking.

Step 25

Braze the ends and remove the pliers.

CHECK AND TEST 2

DIAGNOSIS 2

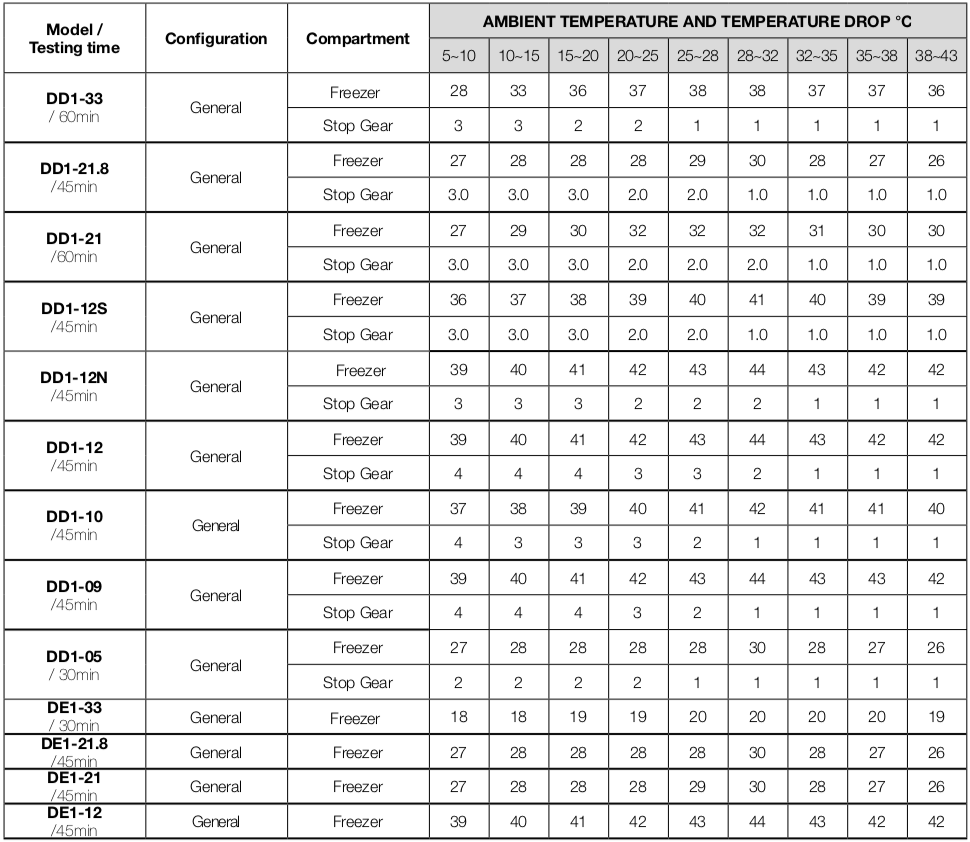

Performance Testing Procedures and Assessment Criteria.

1. Sensor position:

Freezer: geometric center of freezer compartment.

2. Test time: 30min to 60min.

3. Stop Gear: compressor-stopping gear must be above the gear listed on the table.

4. Temperature drop must be no less than the value on the table.