PROCEDURE 1

Step 1

Unscrew bottomattachment.

Step 2

Unscrew topattachment.

Step 3

Remove the plasticcover.

Step 4

Unscrew central

attachment on left and

right side.

Step 5

Unscrew the plasticguider.

Step 6

Hold cabinet and pullappliance out.

Note:

Reverse procedures

above to install the

appliance.

CHECK AND TEST 1

Step 1

Cut off capillary to discharge refrigerant.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhausting pipe.

Step 4

Power up the compressor and feel the exhaust pressure from the exhausting pipe with a piece of paper.

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

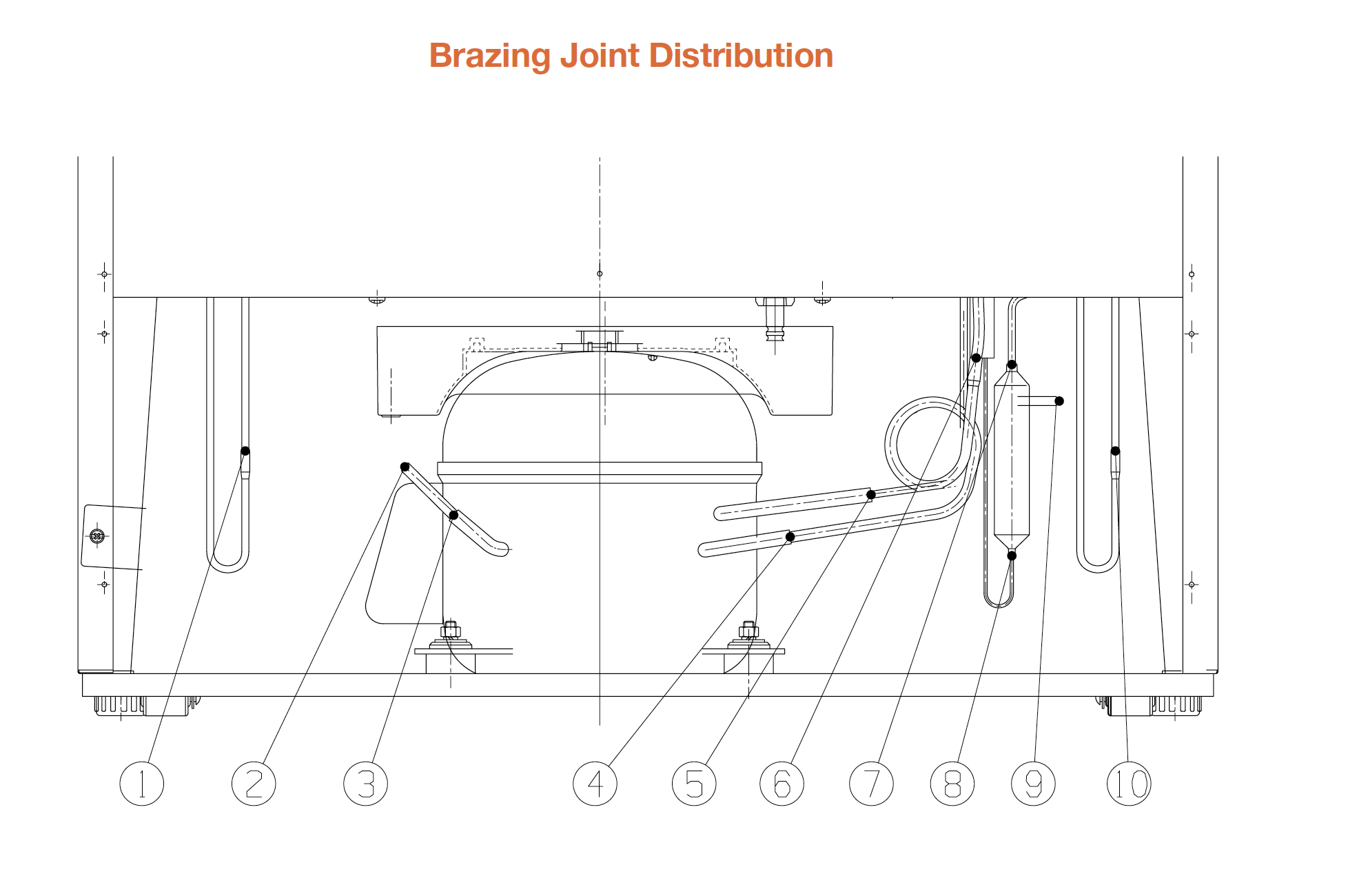

Braze the joints of suction and exhaust pipes.

Step 2

Melt brazing material with flame and pull out processing tube with pliers.

Step 3

Re-braze a copper tube onto processing tube of compressor. Click below link to get more details for brazing requirements, go to Annex B1

Step 4

Clean paint from brazed

joint of drying-filter.

Step 5

Cut off drying-filter.

Step 6

Cut off capillary andshake to remove the cut

end.

Step 7

Braze on a new

drying-filter.

Step 8

Inject nitrogen (1.57Mpa)through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 9

Add quick connectoronto processing pipe of

drying-filter.

Step 2

testo testo

a) First, cut off end

closed to exhaust end

(A in below picture).

b) Then, cut off the end

closed to suction end.

DIAGNOSIS 2

PROCEDURE 2

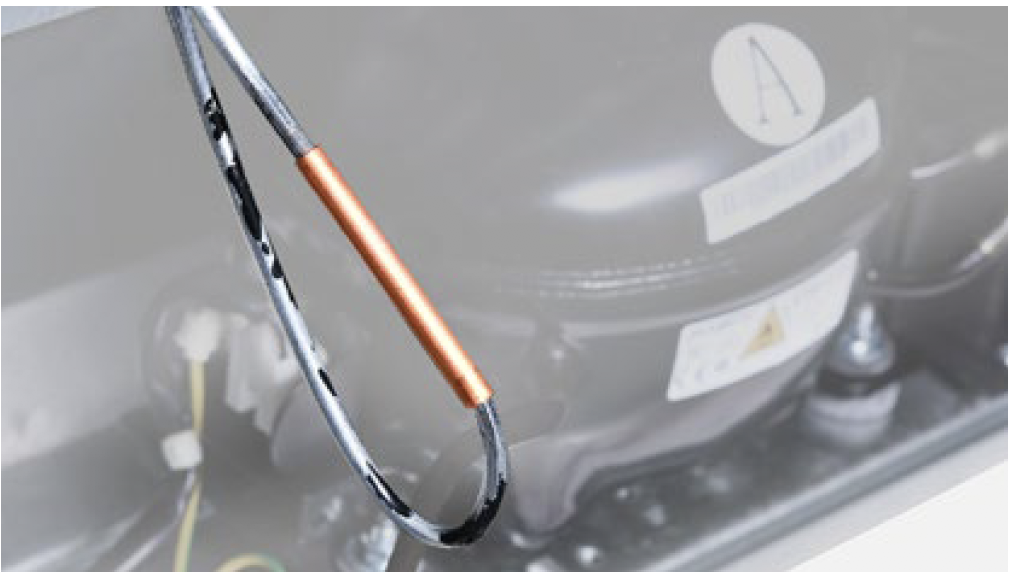

Step 1

Use a larger copper tube

to connect 2 ends of

brazed joints that you

have cut off.

Step 2

Braze the 2 ends.

Step 3

Perform a leakage teston all re-brazed joints

of drying-filter and

compressor processing

pipe.

Step 4

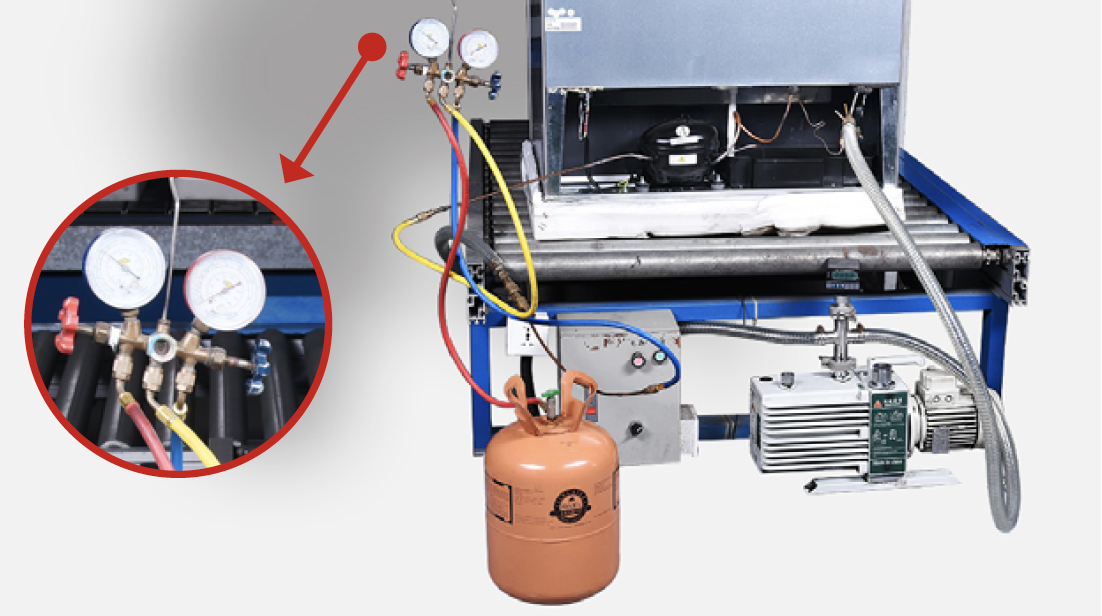

Vacuum and recharge. Click below link to get more details for vocuuming and gas-charging requirements, go to Annex B2

Step 5

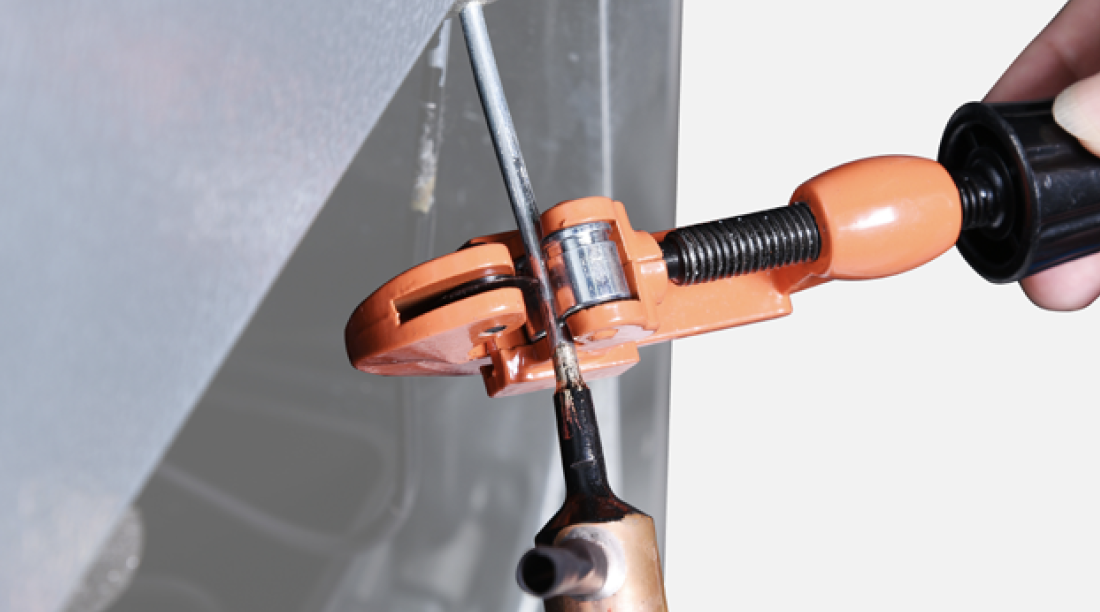

Block processing pipe twice by locking pliers.

Step 6

Leave locking pliers onthe second block and

shake to cut off the rest

of the pipe.

Step 7

Braze the ends and remove the pliers.

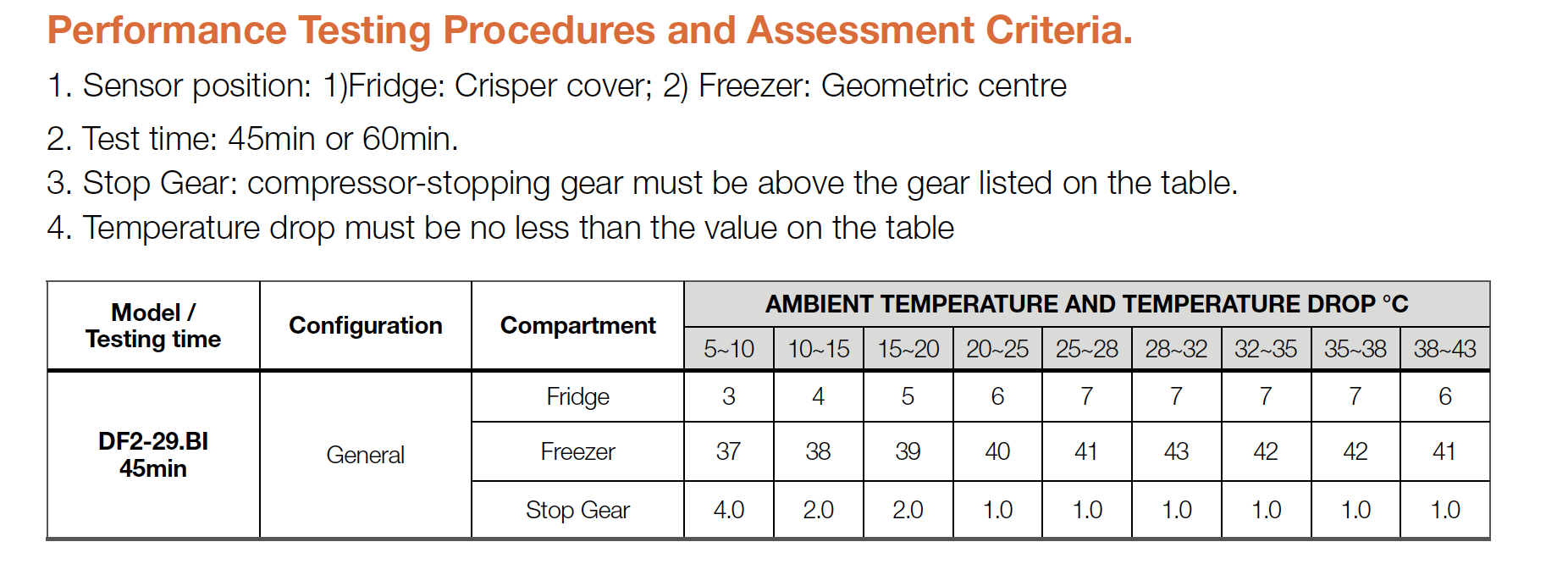

CHECK AND TEST 3

DIAGNOSIS 3