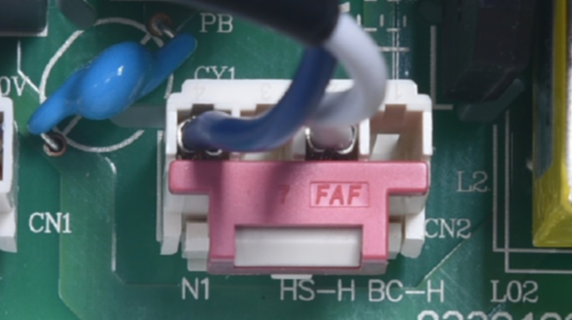

CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a cross-head screwdriver.

Step 2

In PCB area, check if terminal is pushed into final position.

If not, redo it.

Step 3

In PCB area, check if terminal is filled with foam.

Step 4

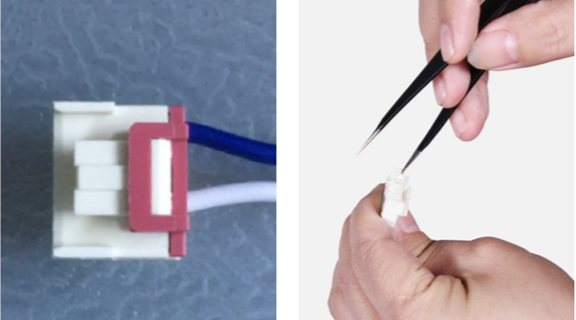

Remove foam with

tweezers.

Step 5

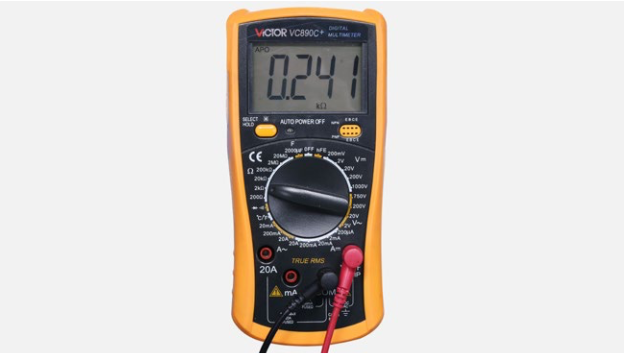

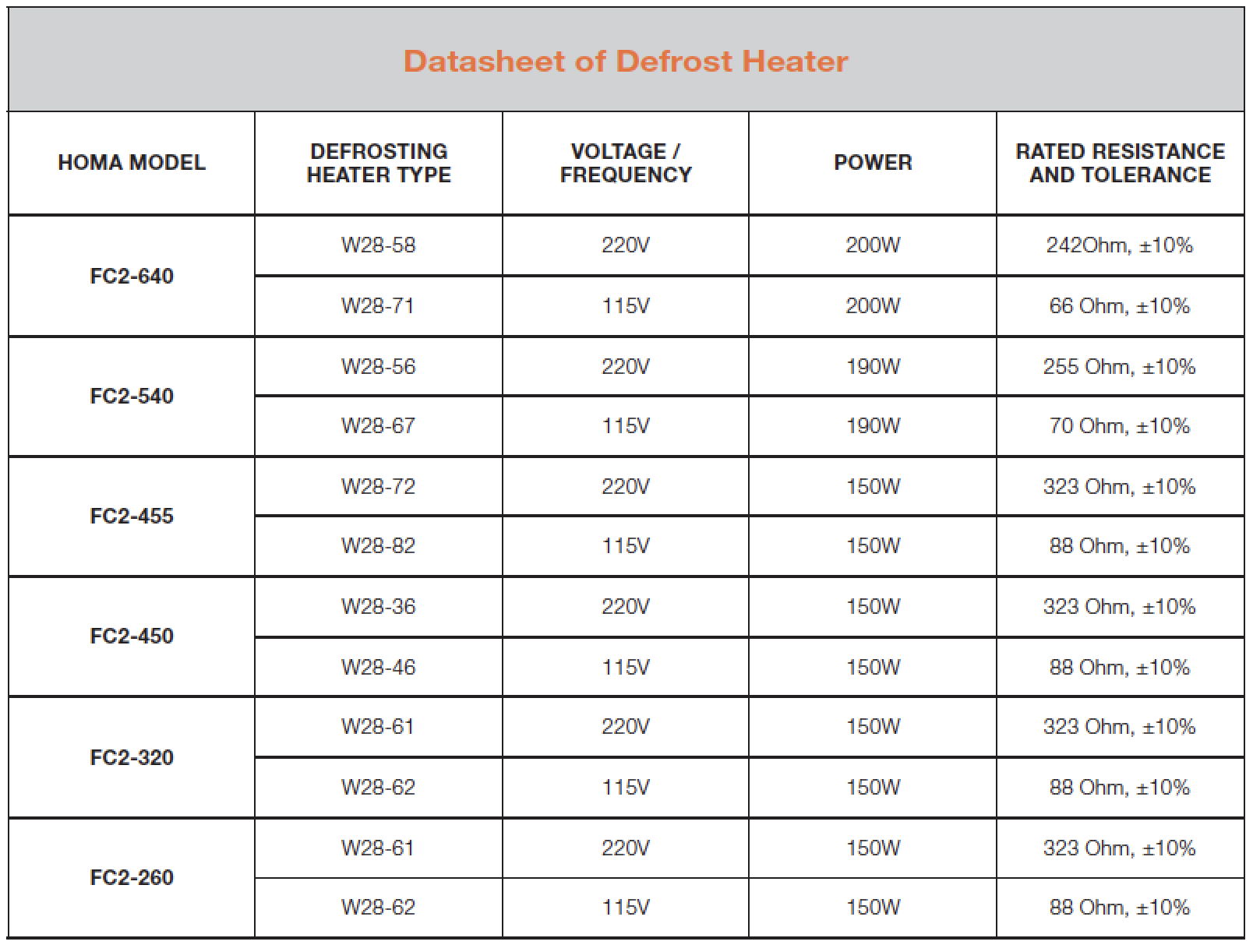

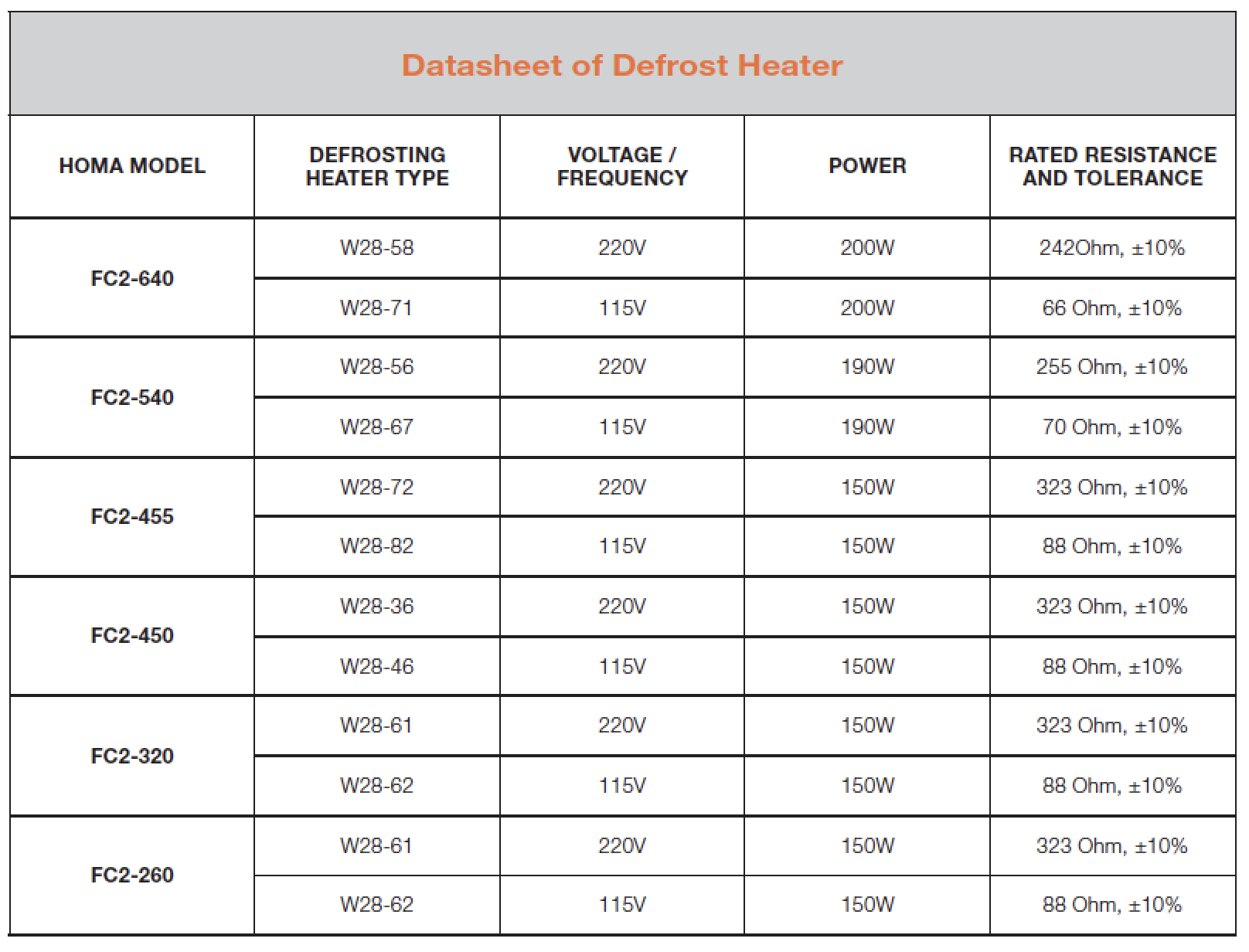

Measure resistance of heater from terminal in PCB area.

Step 6

Check the result.

DIAGNOSIS 1

PROCEDURE 1

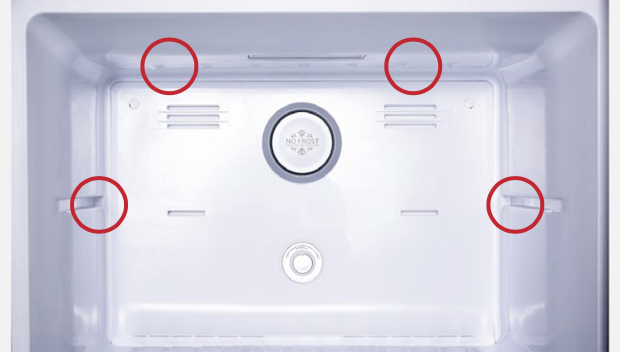

Step 1

Remove freezer shelf.

Step 2

Lever 2 screw covers off.

Step 3

Unscrew 2 screws.

Step 4

Remove air duct:

a.Hold the decorative cover of air duct;

b. Pull air duct out;

c. Disconnect the terminal of fan motor;

d. Take air duct away.

d. Take air duct away.

CHECK AND TEST 2

Step 1

Check if terminal is pushed into final

position.

If not, please re-insert the

terminal into the buckle.

Step 2

Check if the terminal is filled with foam.

Step 3

Remove foam with tweezers.

Step 4

Measure the resistance of heater from terminal in freezer.

DIAGNOSIS 2

PROCEDURE 2

Step 1

Disconnect the terminal of heater.

Step 2

Take out heat- conducting rod with slotted screw driver.

Step 3

Use 6mm cross-head driver to unscrew on left and right.

Step 4

Lift evaporator and heater 20mm, the bottom must be higher than the edge of the trough.

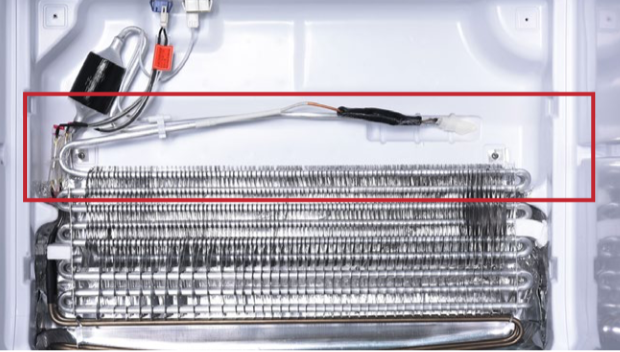

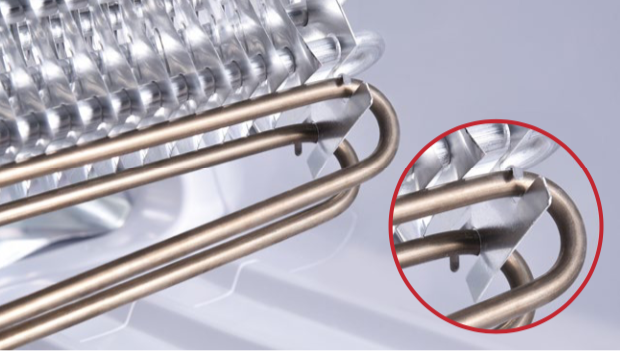

WARNING:

Be careful not to deform

pipes in red square

during steps 4 & 5.

WARNING:

Be careful not to deform pipes in red square during steps 4 & 5.

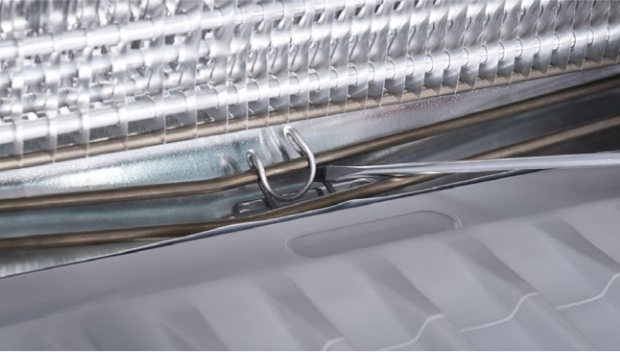

Step 5

Loosen the clips for fastening heater. There are 8 clips in total.

Step 6

Remove the heater.

Reverse procedures

above to reinstall the

heater.

Reverse procedures above to reinstall the heater.

Step 7

Please press the button SW1 on mainboard (within 1 minute of powering on the appliance) to start manual defrost.

DIAGNOSIS 3

CHECK AND TEST 3

Step 1

Connect 2 ends on terminal in PCB area.

Step 2

Check the connection of wires in foam.

DIAGNOSIS 4

Tip 1

When reinstalling air duct, move wires out of the way to prevent crushing by air duct.

Tip 2

After pushing air duct back into position, you should hear a clicking sound. If there is no click, please repeat again.

Tip 3

Check to see if there is a wide gap between air duct and cabinet.

If gap is large, re-install air duct.