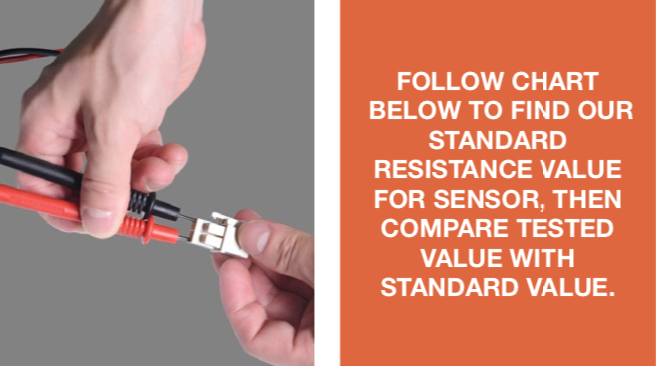

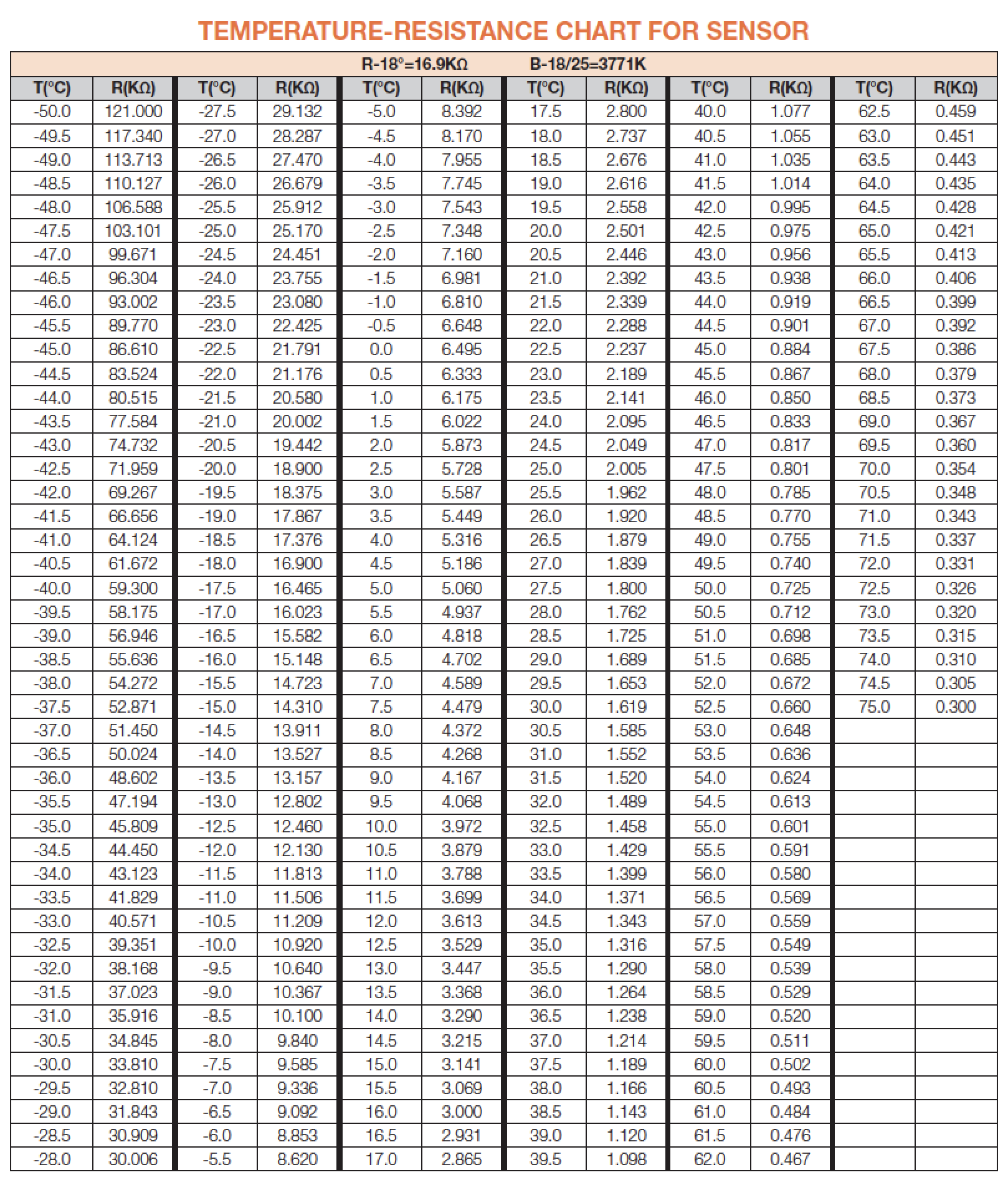

CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

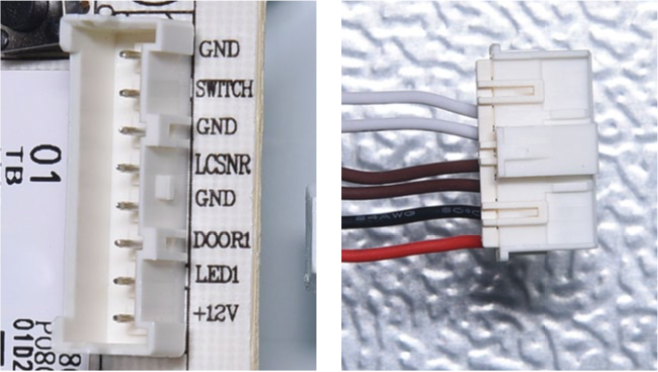

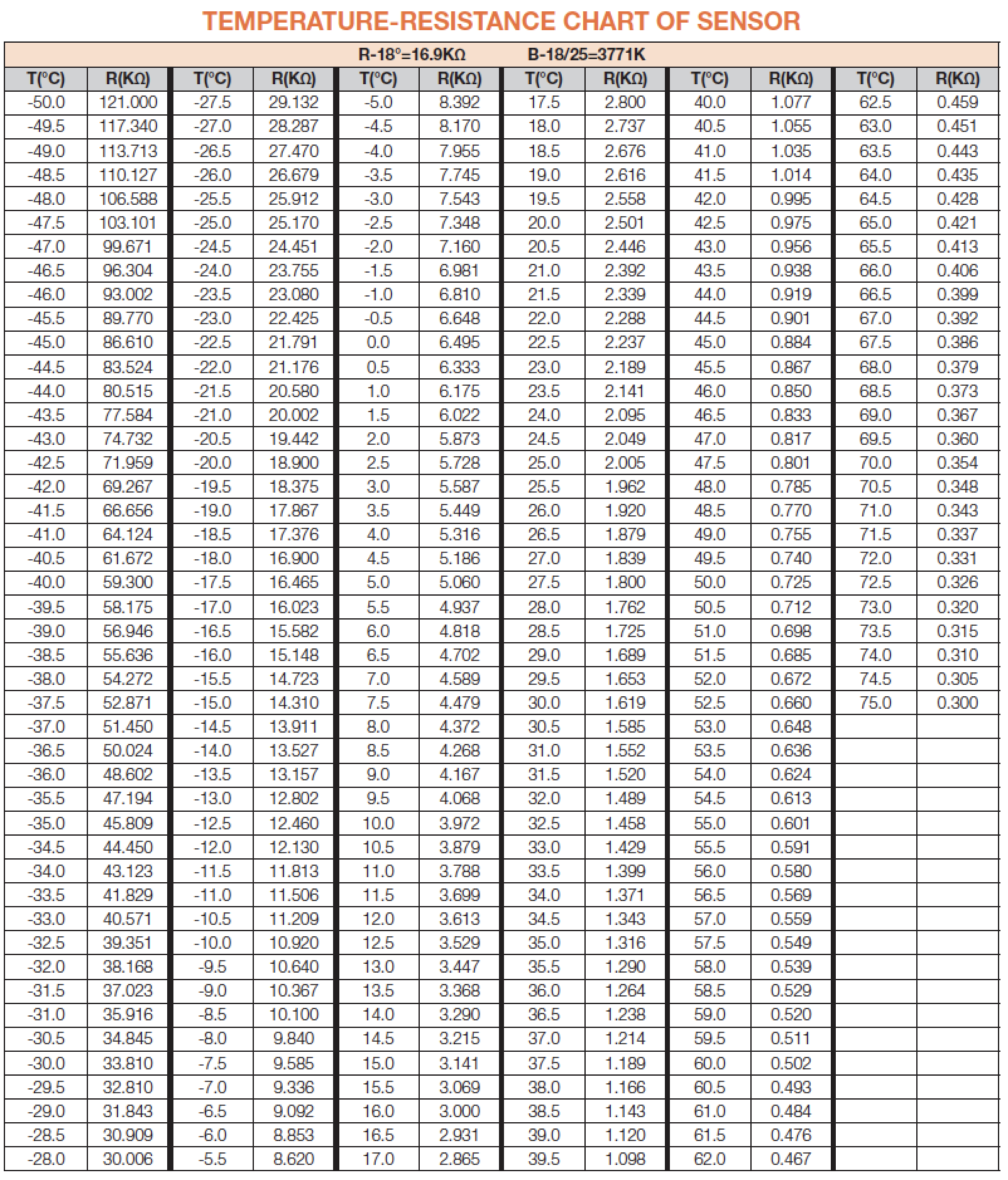

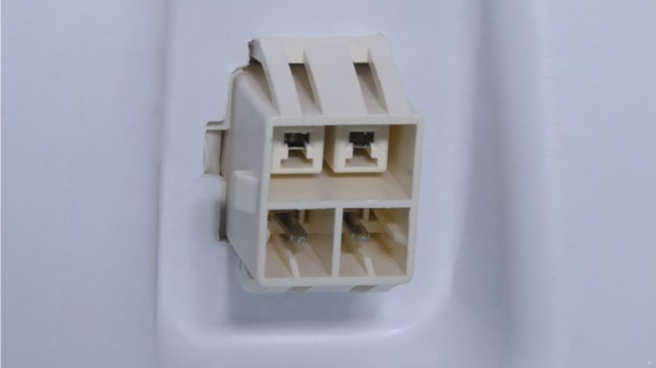

Test resistance of fridge temp. sensor from terminal in PCB area.

Step 3

Take note of value.

Step 4

Measure the temperature of sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove shelves.

Step 2

Remove chill box.

Step 3

Remove chill flap.

Step 4

Lever 2 decorative strips off and remove.

Step 5

Remove the 4 screws.

Step 6

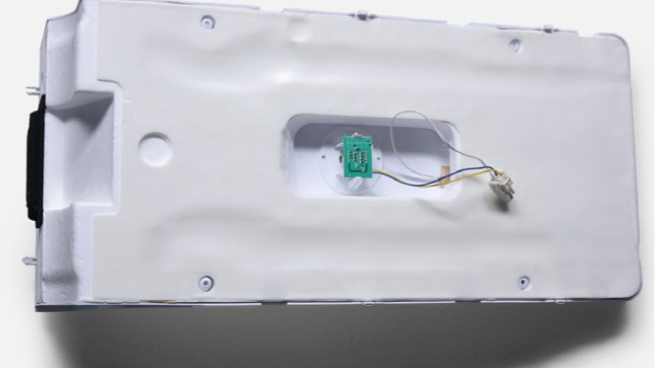

Pull out fridge air duct.

Step 7

Disconnect the terminals.

DIAGNOSIS 2

PROCEDURE 2

Step 1

Remove knob or cover.

Step 2

Loosen clasps.

Step 3

Remove foam.

Step 4

Take off the tape and remove the sensor.

Reverse procedures above to reinstall fridge air duct.

Reverse procedures above to reinstall fridge air duct.

Step 5

Make sure the sensor wires are fixed well.

DIAGNOSIS 3

CHECK AND TEST 2

Step 1

Take off the tape and remove the sensor.

Step 2

Remove foam with tweezers.

Step 3

Check if the connections of wires in foam are good or not.

Step 4

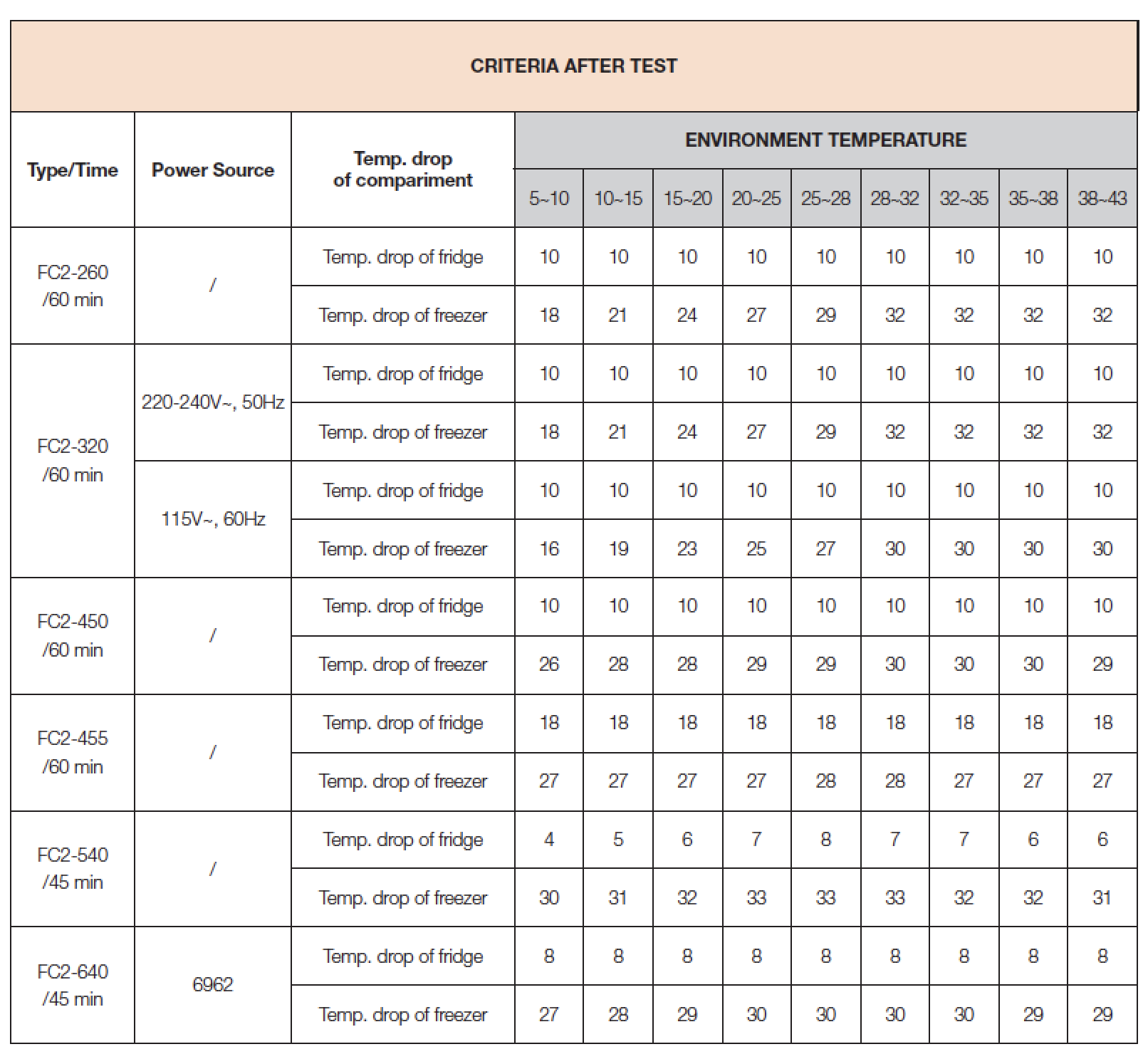

After reworking, please follow procedures and criteria below to do a performance test.

DIAGNOSIS 4

Performance Test Procedures for Assessing Criteria for Model FC2 series

1 Ambient temperature and humidity are the same as natural conditions.

2 Sensor position close to air outlet.

3 Testing time 45 or 60 minutes.

4 Set thermostat to MAX.

Tip 1

When reinstalling fridge air duct, first put the positive end of buckle on the top into the negative ends.

Tip 2

Then put the positive end of buckle on the sides into the negative ends.

Tip 3

Later, fasten the buckles on the sides by knocking them in.