CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

In PCB area, check if terminal is pushed into final position.

Step 3

In PCB, check to see if terminal is filled with foam.

Step 4

If so, use tweezers to

remove it.

Step 5

In PCB area, use multimeter to measure resistance value.

Step 6

Take note of the result.

Step 7

Measure the temperature of freezer air duct, close to sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove freezer shelf.

Step 2

Lever 2 screw covers off.

Step 3

Unscrew 2 screws.

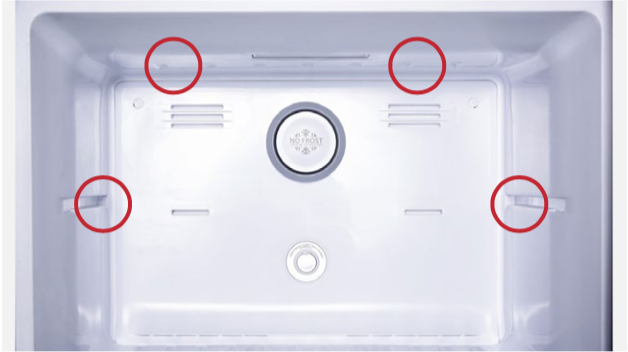

Step 4

Remove air duct:

a. Hold the decorative cover of air duct;

b. Pull air duct out;

c. Disconnect the terminal

of fan motor;

c. Disconnect the terminal of fan motor;

d. Remove freezer air

duct.

d. Remove freezer air duct.

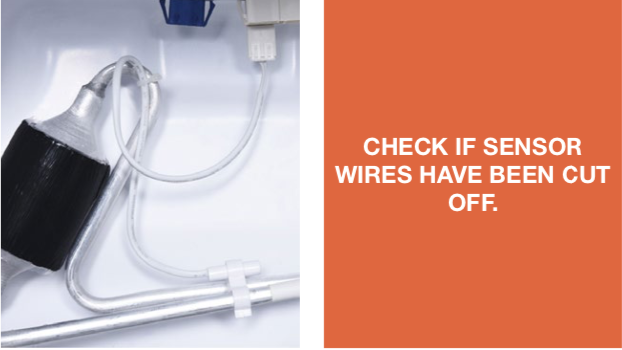

DIAGNOSIS 2

PROCEDURE 2

Step 1

Cut wire off from broken area.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and connect them.

Step 4

Tin soldering.

Step 5

Cover connection with

electrical tape.

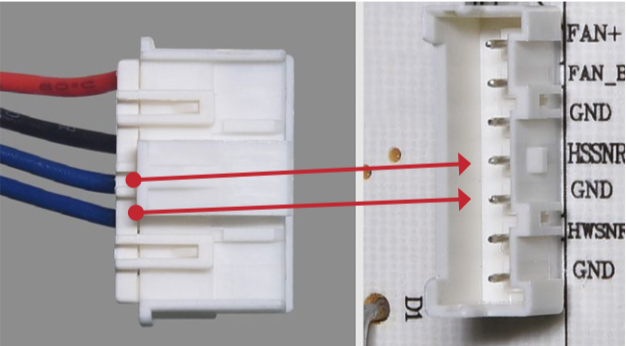

CHECK AND TEST 2

Step 1

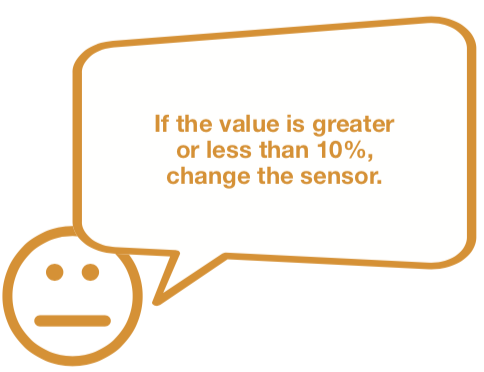

Use a multimeter to measure the resistance value of defrosting temp. sensor from terminal located in freezer.

Step 2

Read the value.

Step 3

Measure the temperature of sensor.

DIAGNOSIS 3

CHECK AND TEST 3

Step 1

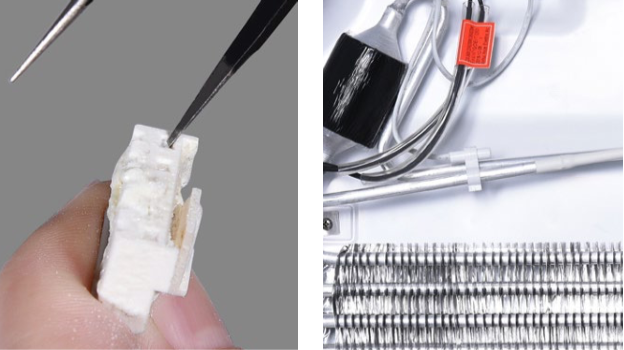

Check to see if the terminal is filled with foam.

Step 2

If so, use tweezers to crush and remove foam.

Step 3

Make sure sensor is

properly located by

comparing with photo on

right.

If sensor is not in same position as photo, fix it.

Step 4

Connect the 2 ends in PCB area.

DIAGNOSIS 4

Tip 1

When reinstalling air duct, move wires out of the way to prevent crushing by air duct.

Tip 2

After pushing air duct back into position, you should hear a clicking sound. If there is no click, please repeat again.

Tip 3

Check to see if there is a wide gap between air duct and cabinet.

If gap is large, re-install air duct.