CHECK AND TEST 1

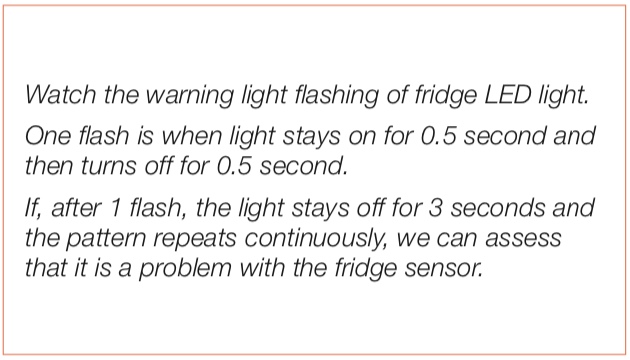

Note

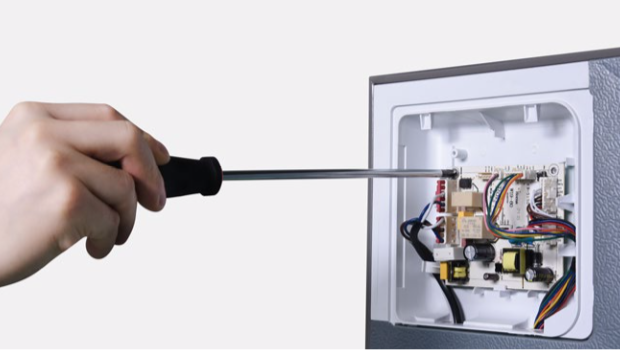

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

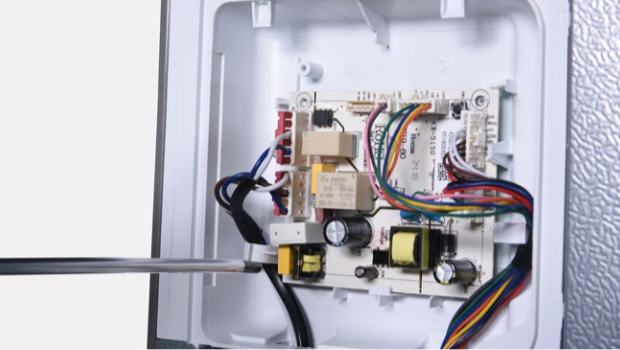

Step 2

Check if the terminal is filled with foam or not, then test resistance of sensor from terminal in PCB area.

Step 3

Take note of value.Step 4

Measure the temperature of sensor.

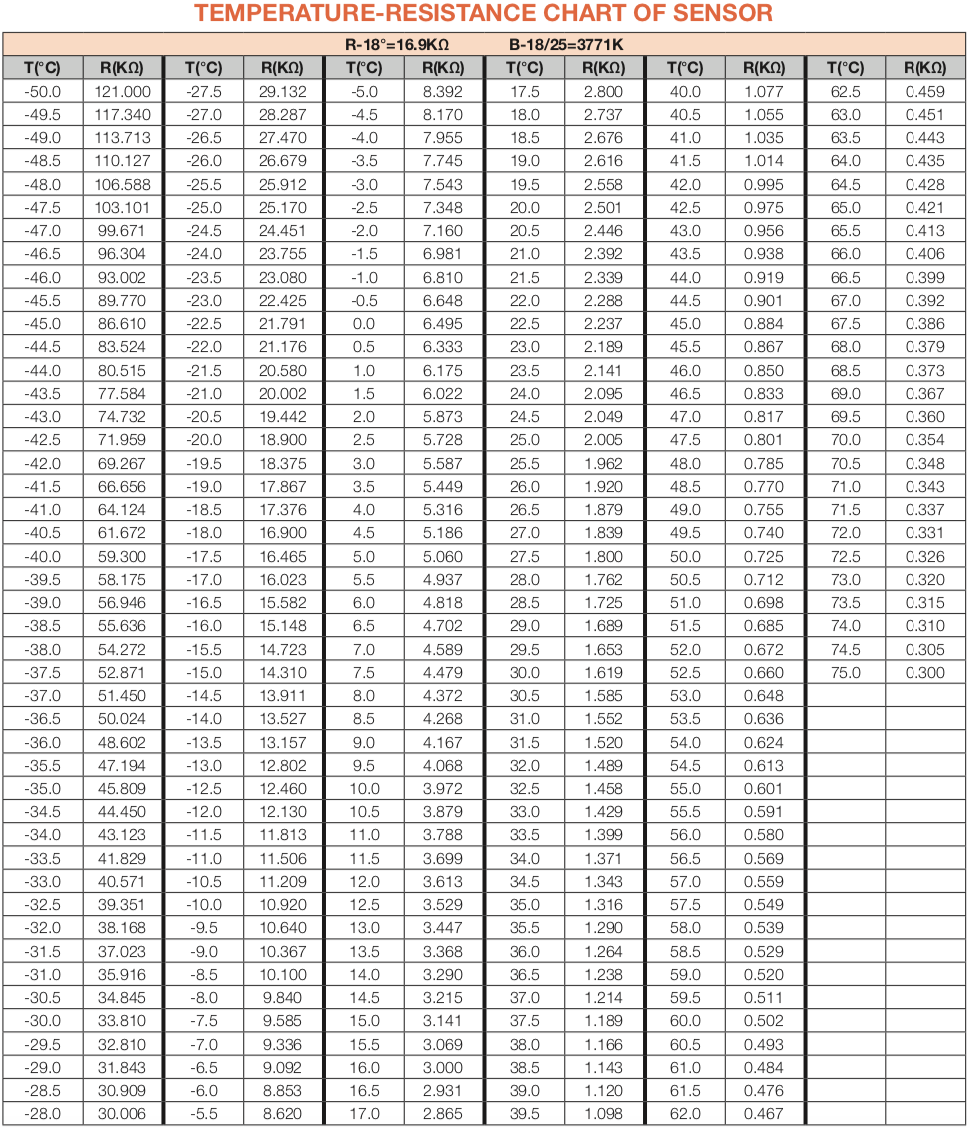

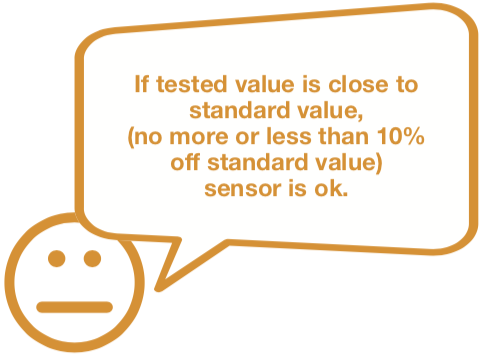

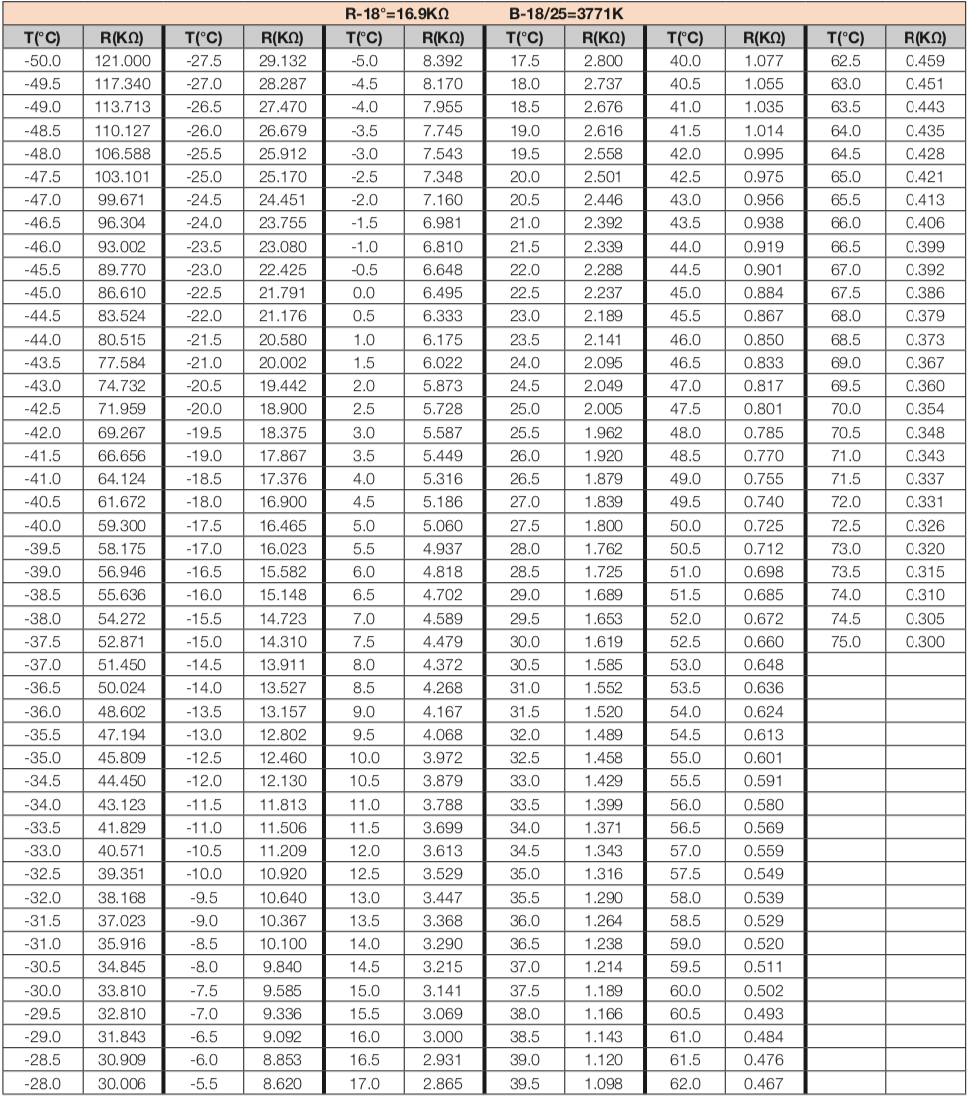

Using the tested temperature, find out the standard resistance value in table below.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove shelves.

Step 2

Remove chill box.

Step 3

Remove chill flap.

Step 4

Lever 2 decorative strips off and remove.Step 5

Remove the 4 screws.

Step 6

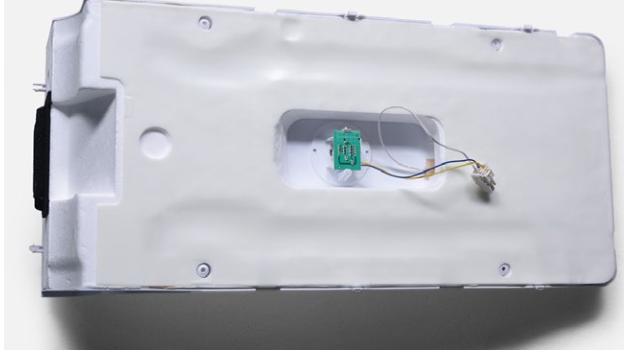

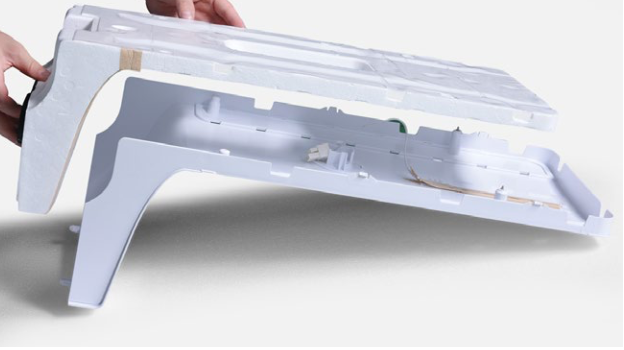

Pull out fridge air duct.

Step 7

Disconnect the terminals.

CHECK AND TEST 2

Step 1

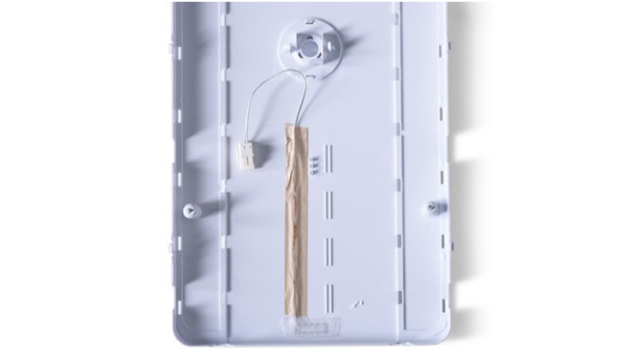

Test resistance of sensor from terminal in duct cover.

Step 2

Measure the temperature of sensor.

DIAGNOSIS 2

PROCEDURE 2

Step 1

Remove knob or cover.

Step 2

Loosen clasps.

Step 3

Remove foam.

Step 4

Take off the tape and remove the sensor.

Step 5

Make sure the sensor wires are fixed well.Reverse procedures above to reinstall fridge air duct.

DIAGNOSIS 3

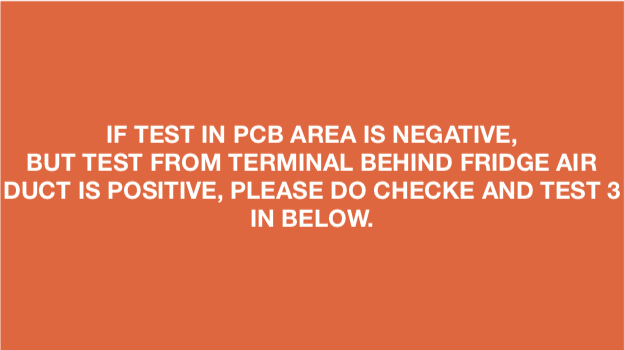

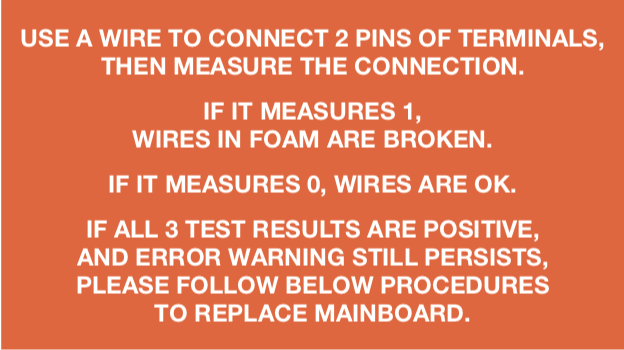

CHECK AND TEST 3

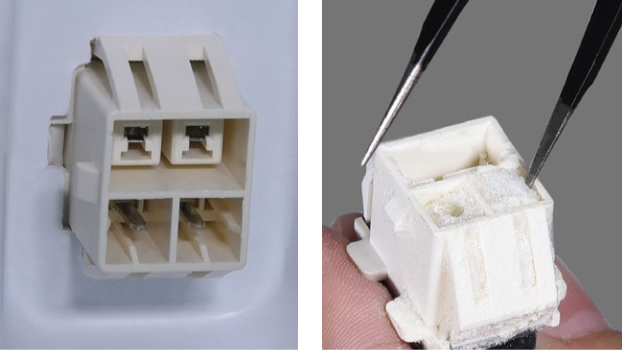

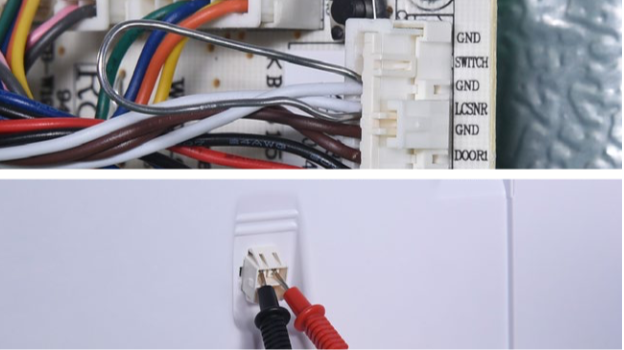

Step 1

Check if terminal is full of foam.Step 2

Remove foam with tweezers.

Step 3

Check if the connections of wires in foam are good or not.

DIAGNOSIS 4

PROCEDURE 3

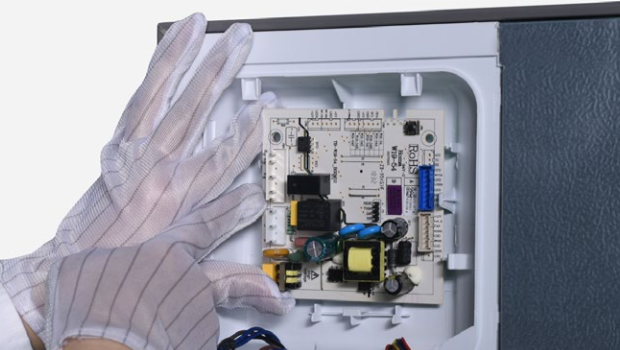

Step 1

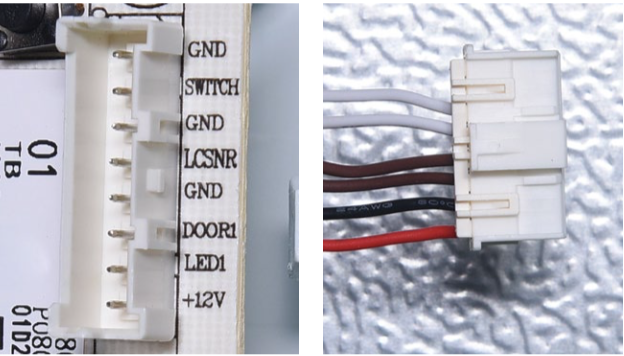

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

Unscrew the mainboard.

Step 3

Pull out the buckle to take out wires.

Step 4

Disconnect terminals.

Step 5

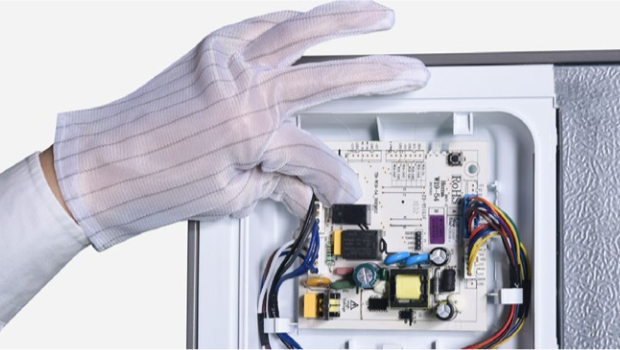

Pull out the buckle to remove mainboard.Reverse above steps to install a new board.

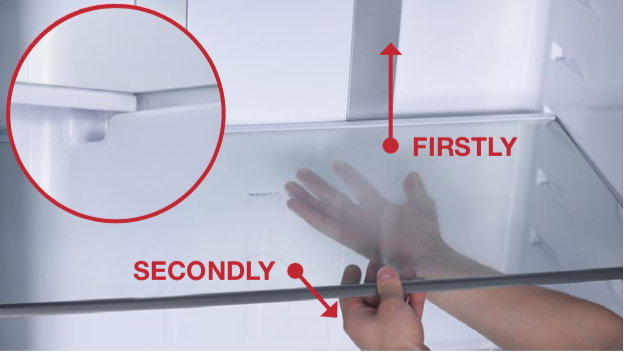

Tip 1

When reinstalling fridge air duct, first put the positive end of buckle on the top into the negative ends.

Tip 2

Then put the positive end of buckle on the sides into the negative ends.

Tip 3

Later, fasten the buckles on the sides by knocking them in.