CHECK AND TEST 1

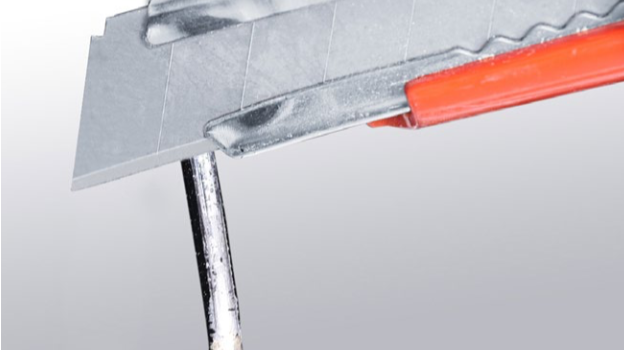

Step 1

Discharge refrigerant: Use a pair of pliers to cut off the charging tube.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 4

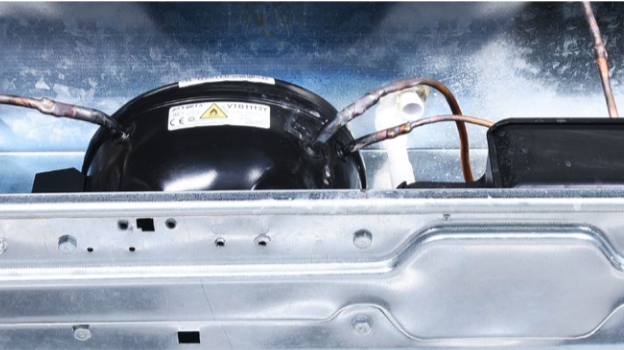

Re-braze a copper tube onto processing tube of compressor.

To get more details on brazing requirements, please go to Annex B1.

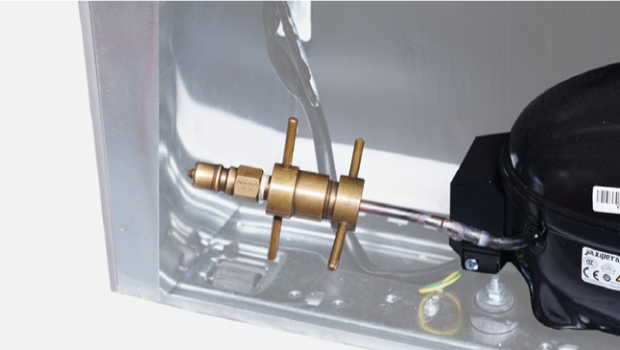

Step 5

Install quick connector onto processing pipe.

Step 6

Use a pliers to cut the capillary off.

Step 7

Inject nitrogen (1.57Mpa)

through quick connector

into pipe.

Step 8

Check to see if gas is blowing out of capillary.

Step 9

Cut off exhaust pipe to check whether oil is being ejected from compressor.

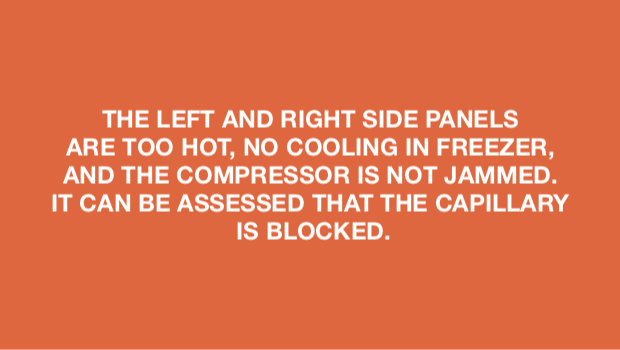

DIAGNOSIS 1

PROCEDURE 1

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover.

Step 3

Disconnect all terminals.

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut of compressor.

Step 6

Install a new compressor on top.

Step 7

Weld the joints of suction and exhasuting pipes.

Step 8

Re-braze a copper tube onto processing tube of compressor.

To get more details on brazing requirements, please go to Annex B1.

PROCEDURE 2

Step 1

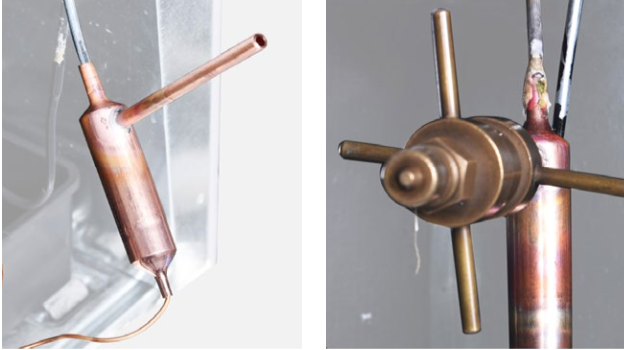

Clean away paint on brazed joint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and remove the cut end by shaking.

Step 4

Braze on a new drying-filter.Step 5

Add quick connector onto processing pipe of drying-filter.

Step 6

Do leakage test on brazed joints of drying- filter and compressor processing pipe.

Step 7

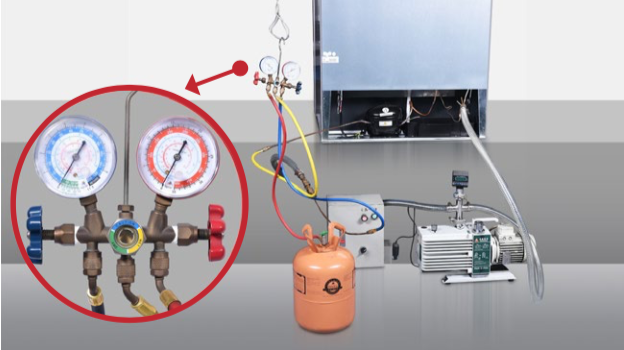

Vacuum and recharge.

Click below link to get more details for

vacuuming and gas-

charging requirements,

on Annex B1.

Step 8

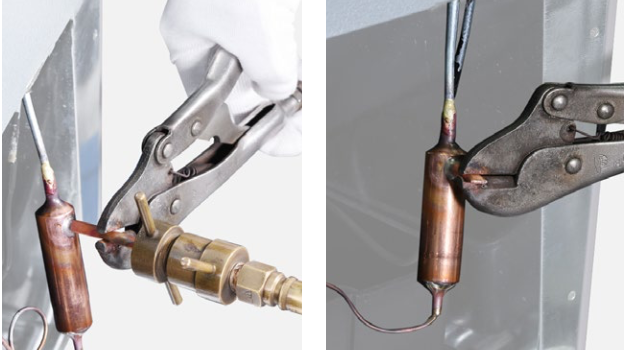

Block processing pipe twice with locking pliers.

Step 9

Leave locking pliers on the second block and shake to cut off the rest of pipe.

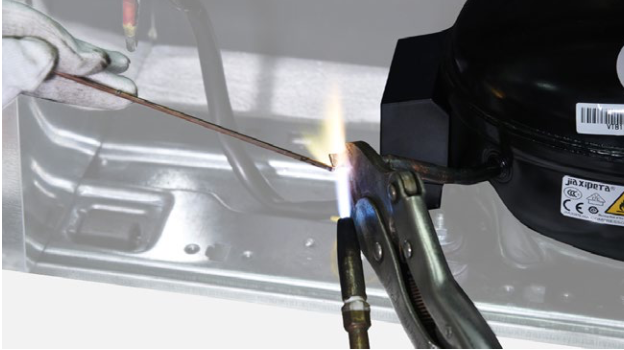

Step 10

Braze the ends and remove the pliers.

DIAGNOSIS 2

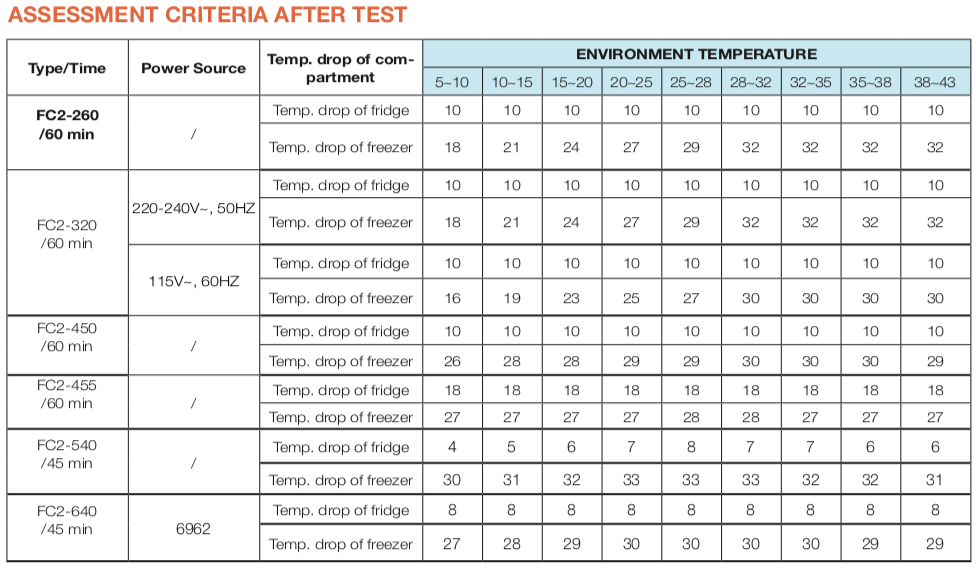

Performance Testing Procedures and Assessment Criteria for FC2 Series

Test conditions

1 Ambient temperature and humidity are the same as natural conditions.

2 Sensor position close to air outlet.

3 Testing time 45 or 60 minutes.

4 Set thermostat at MAX.