Step 1

Discharge refrigerant:

Cut off the charging tube

with pliers.

Step 2

Discharge all refrigerant toward the exhaust vent

Step 3

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 4

Re-braze a copper tube onto compressor processing tube. Click below link to get more details for brazing requirements, go to Annex B1

Note

Step 5

Install quick connectoronto re-brazed pipe.

Step 6

Inject nitrogen gas

with 1.57Mpa pressure

through quick connector

into pipe.

Step 7

Use a pliers to cut the capillary off.

Step 8

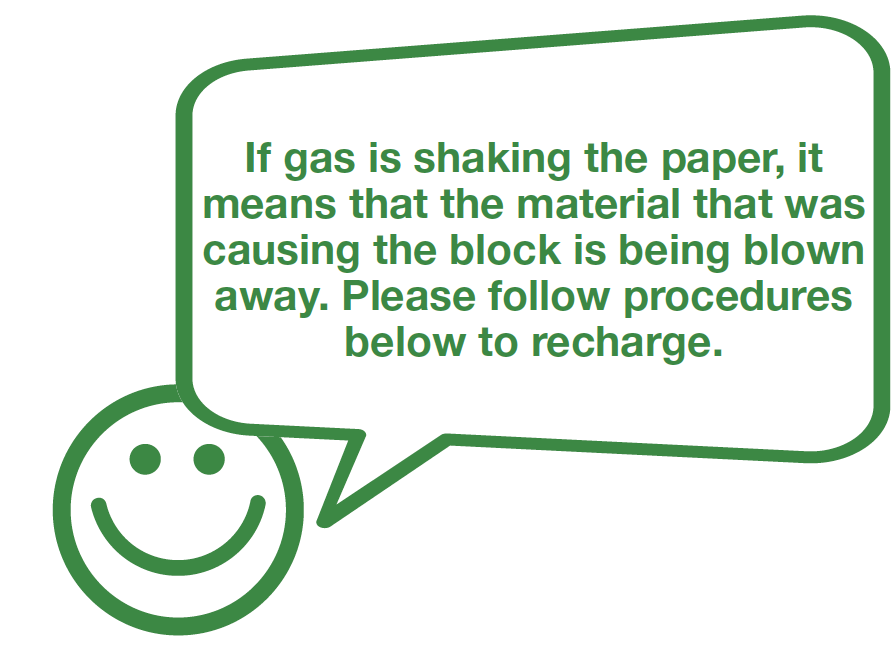

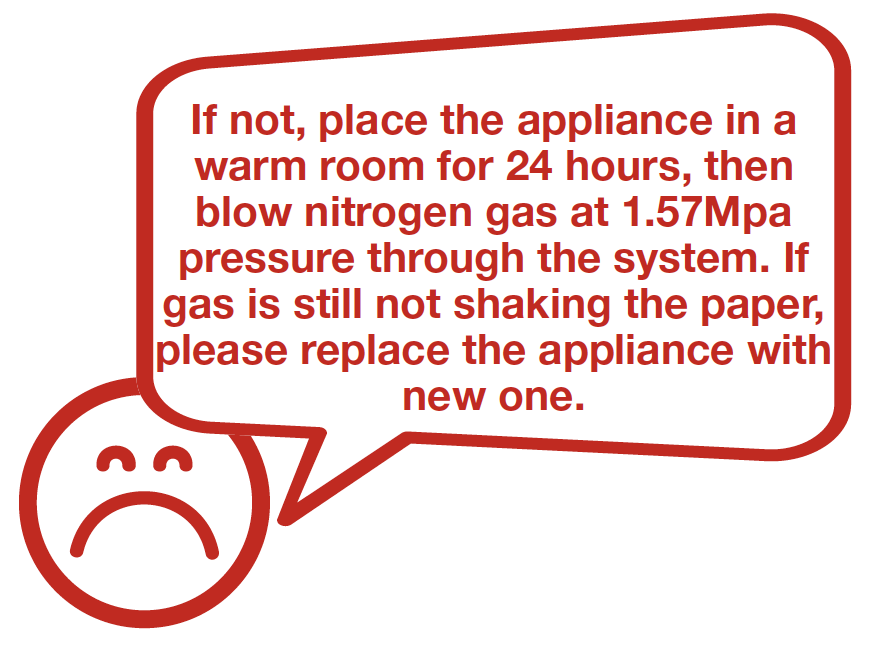

Check if gas is blowing out from capillary.

Step 9

Block the end of filter toblow capillary for at least

3 min.

DIAGNOSIS 1

PROCEDURE 2

Step 1

Clean paint off of brazedjoint of drying filter.

Step 2

Cut off the brazed joint of

drying filter.

Step 3

Cut off capillary and

remove the cut end by

shaking.

Step 4

Braze on a new dryingfilter.

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Test for leaks on brazedjoints of drying-filter

and processing pipe on

compressor.

Step 8

Vacuum and recharge.Click below link to

get more details for

vacuuming and gascharging

requirements,

go to Annex b2

Step 9

Block processing pipetwice by locking pliers.

the second block and

cut off the rest of the

pipe by shaking.

Step 11

Braze the ends and remove the pliers.

DIAGNOSIS 2