PROCEDURE 1

Step 1

Unscrew bottomattachment.

Step 2

Unscrew topattachment.

Step 3

Remove the plasticguider cover.

Step 4

Unscrew the plasticguider.

Step 5

Hold cabinet and pullappliance out.

Note:

Reverse procedures

above to install the

appliance.

Step 1

Cut off capillary to discharge refrigerant.

Step 2

Discharge all refrigerant

toward the exhaust vent.

Step 3

Cut off exhaust pipe and

suction pipe.

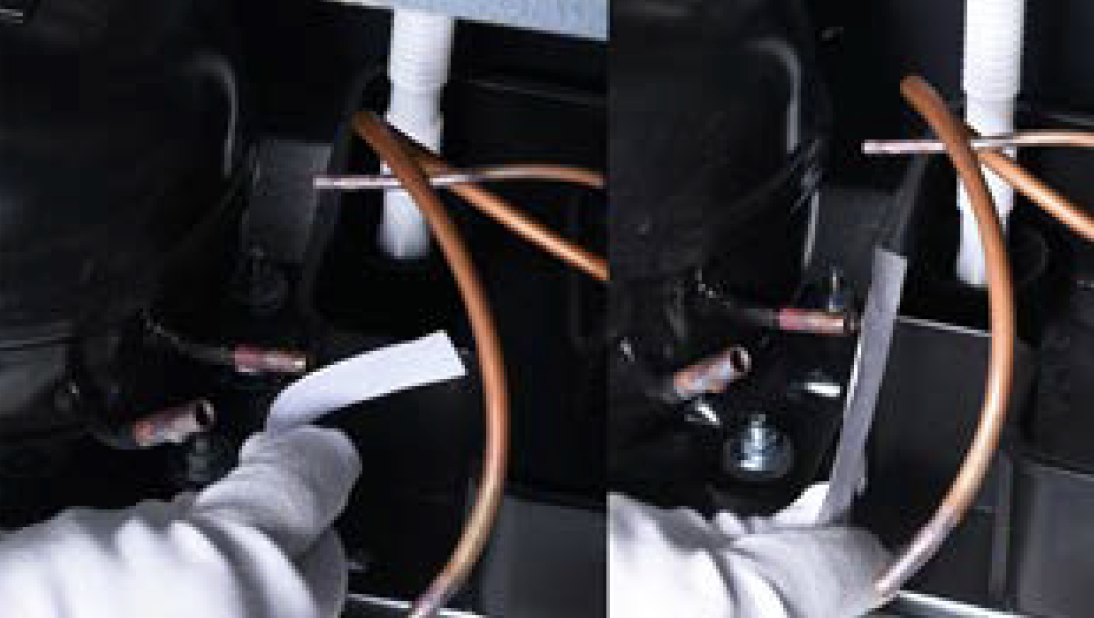

Step 4

Power up the compressor and feel the exhaust pressure from the exhausting pipe with a piece of paper.

DIAGNOSIS 1

CHECK AND TEST 2

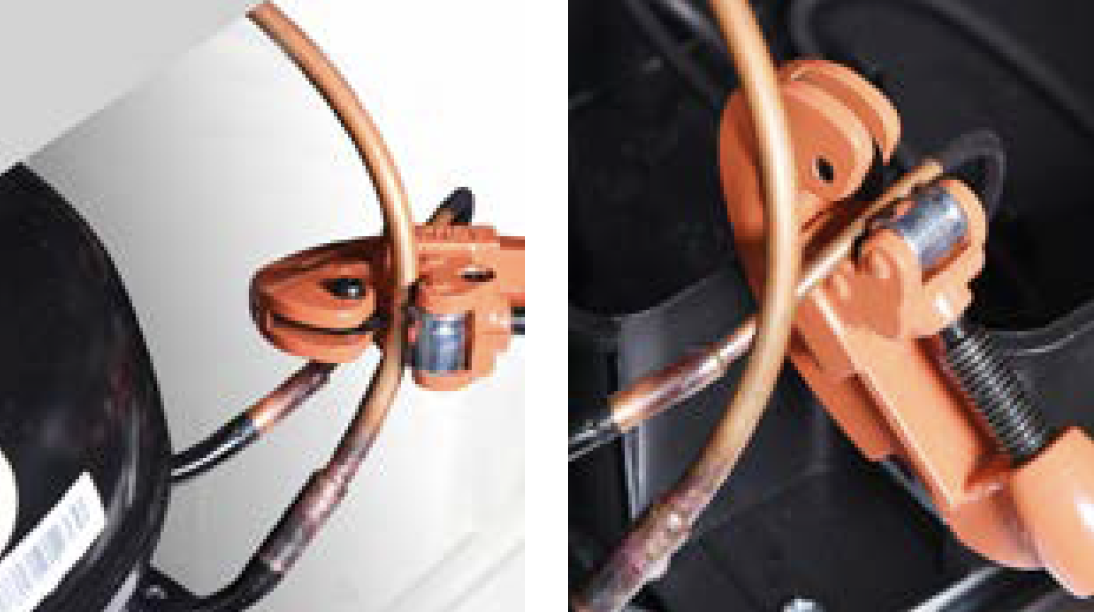

Step 1

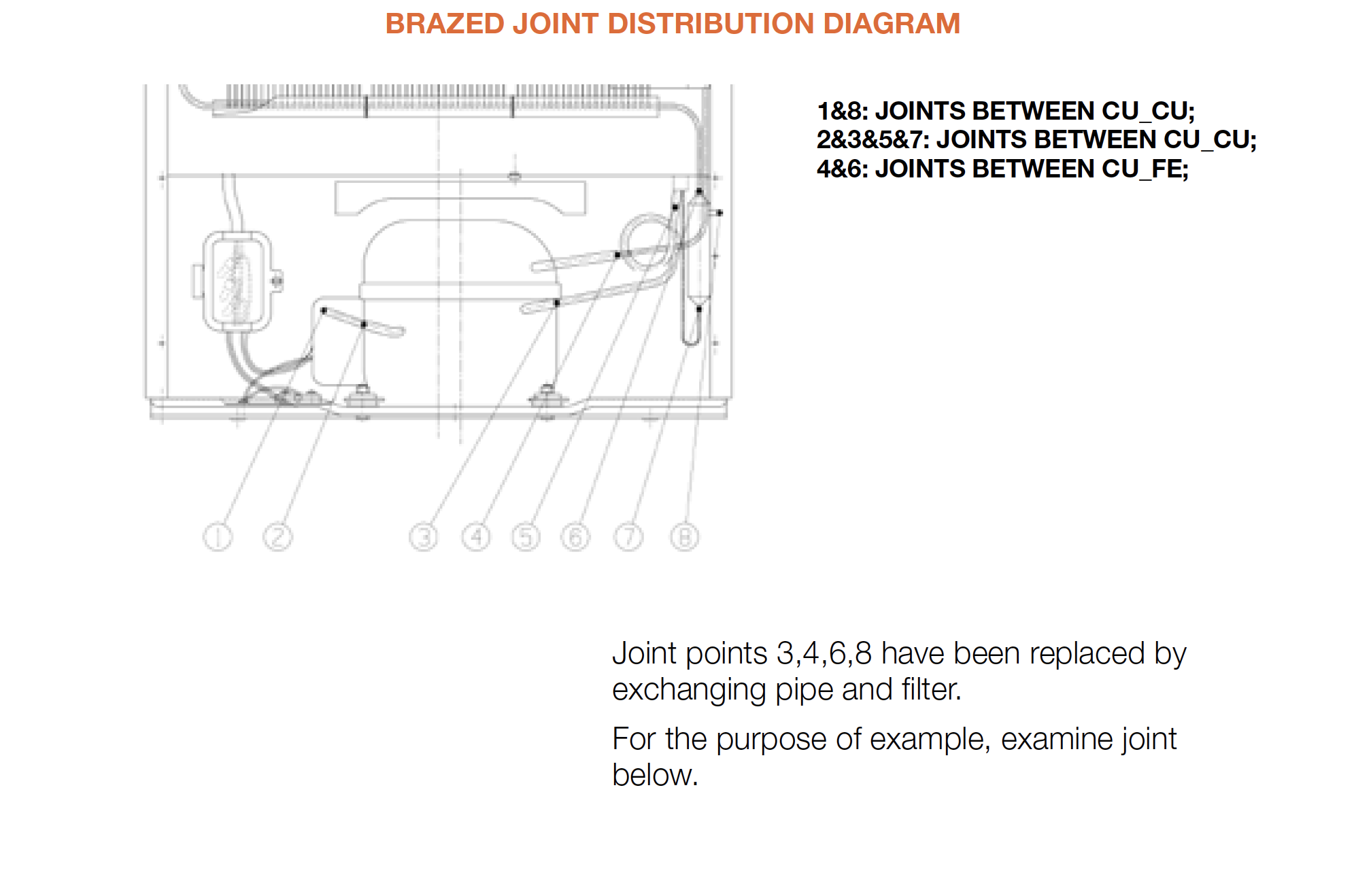

Braze the joints of suction and exhaust pipes.

Step 2

Melt brazing material with flame and pull out processing tube with pliers.

Step 3

Re-braze a copper tube onto processing tube of compressor. Click below link to get more details for brazing requirements, go to Annex B1

Note

Step 4

Clean paint from brazedjoint of drying-filter.

Step 5

Cut off drying-filter.

Step 7

Braze on a newdrying-filter.

Step 8

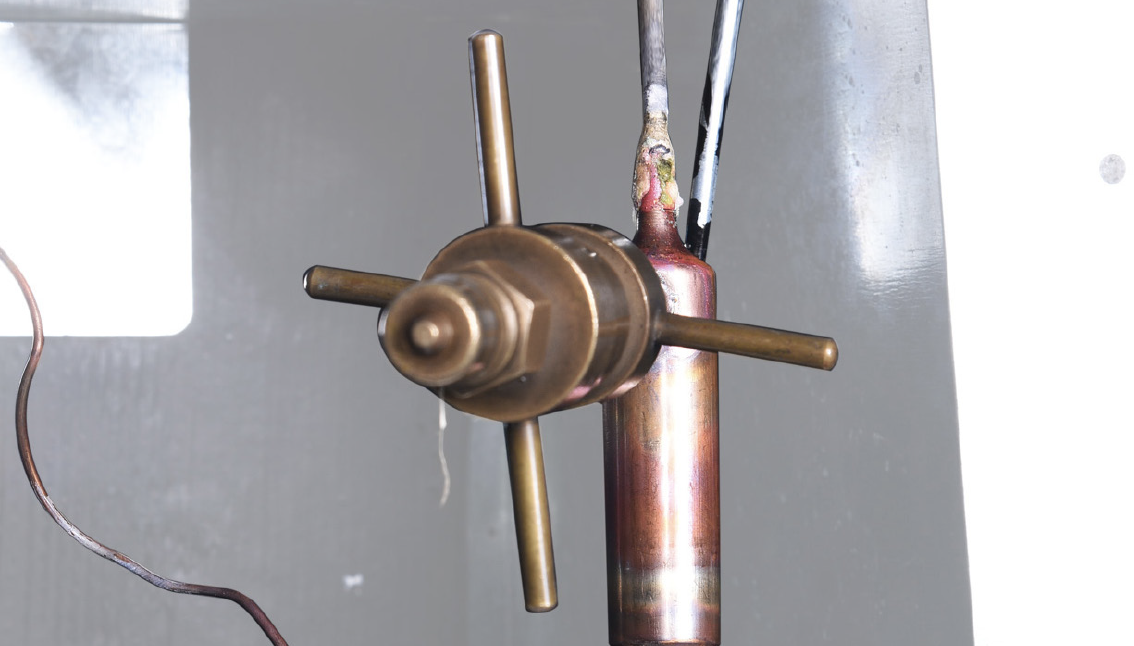

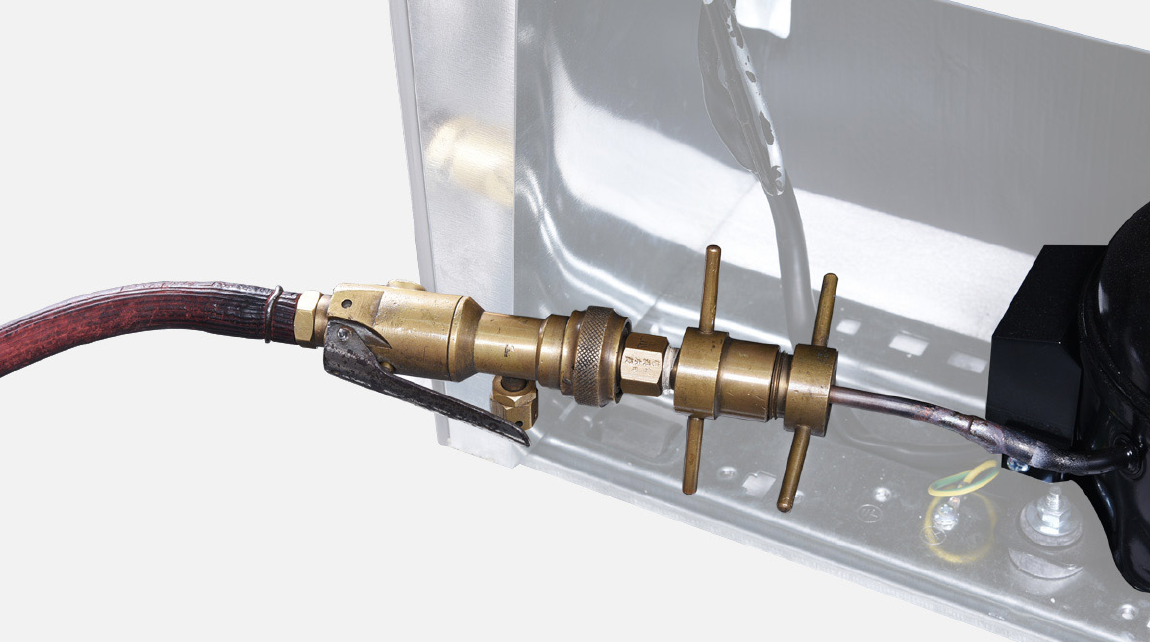

Add quick connectoronto processing pipe of

drying-filter.

Step 9

Inject nitrogen (1.57Mpa)through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 10

Cut off brazed joints, oneby one, to find blockage

point.

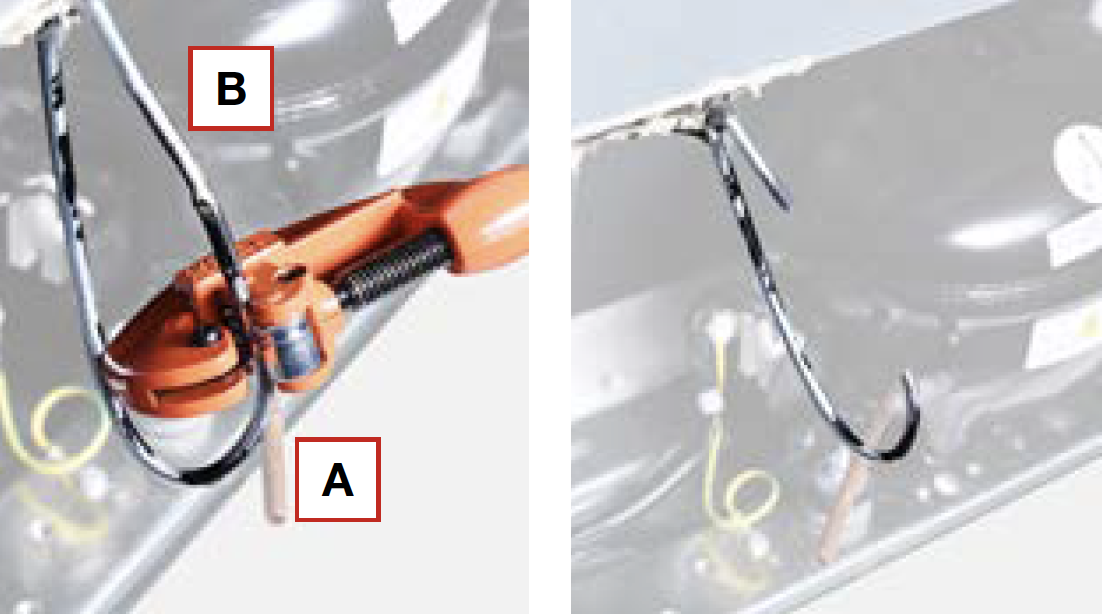

Step 11

First, cut off end

closed to exhaust end

(A in below picture).

Step 12

Then, cut off the end

closed to suction end.

DIAGNOSIS 2

PROCEDURE 2

Step 1

Use a larger copper tube to connect 2 ends of brazed joint.

Step 2

Braze the 2 ends.

Step 3

Perform a leakage teston all re-brazed joints

of drying-filter and

compressor processing

pipe.

Step 4

Vacuum and recharge. Click below link to get more details for vocuuming and gas-charging requirements, go to Annex B2

Step 5

Block processing pipe twice by locking pliers.

Step 6

Leave locking pliers onthe second block and

shake to cut off the rest

of the pipe.

Step 7

Braze the ends and

remove the pliers.

DIAGNOSIS 3