PROCEDURE 1

Step 1

Unscrew bottomattachment.

Step 2

Unscrew topattachment.

Step 3

Unscrew the plasticguider.

Step 4

Hold cabinet and pullappliance out.

Step 1

Cut off capillary to

discharge refrigerant.

Step 2

Discharge all refrigeranttoward the exhaust vent.

Step 3

Cut off exhaust pipe and suction pipe.

Step 4

Power up the compressor and feel the exhaust pressure from the exhaust pipe with a piece of paper.

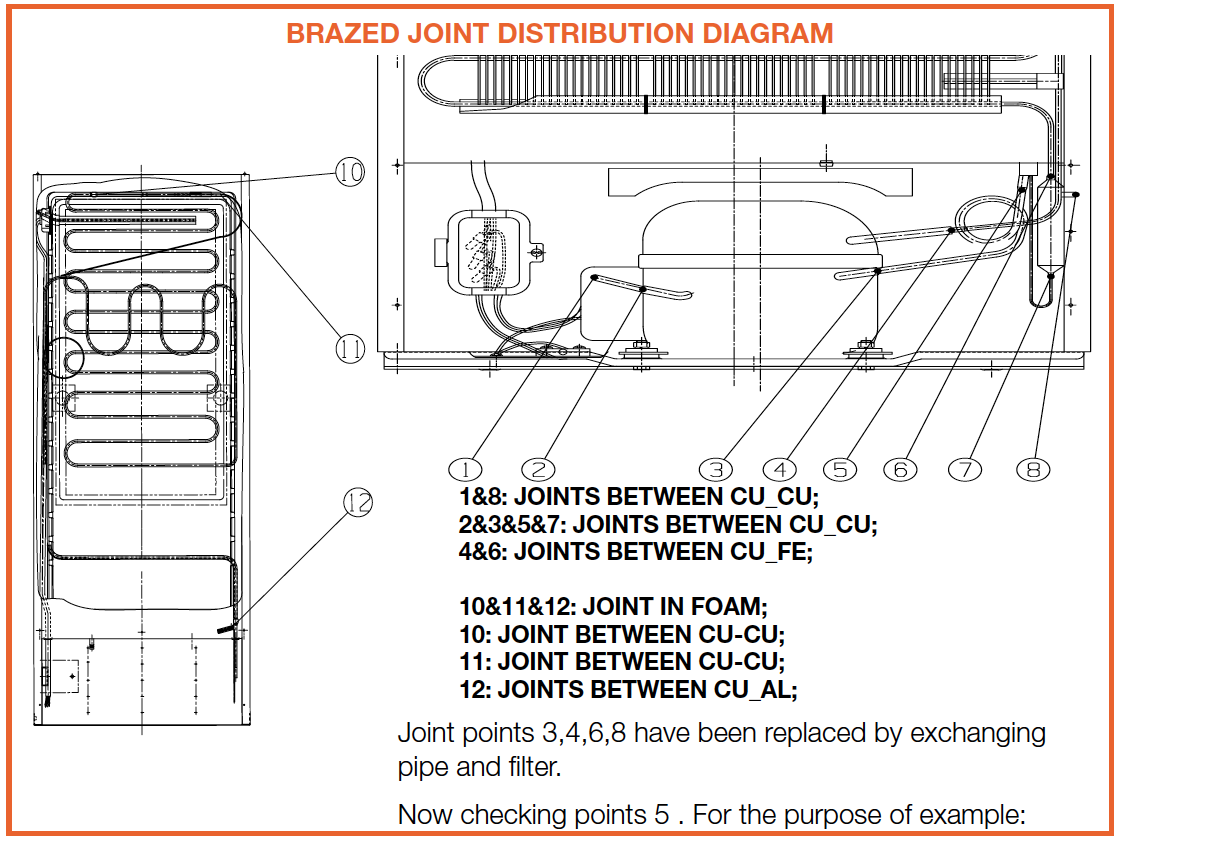

DIAGNOSIS 1

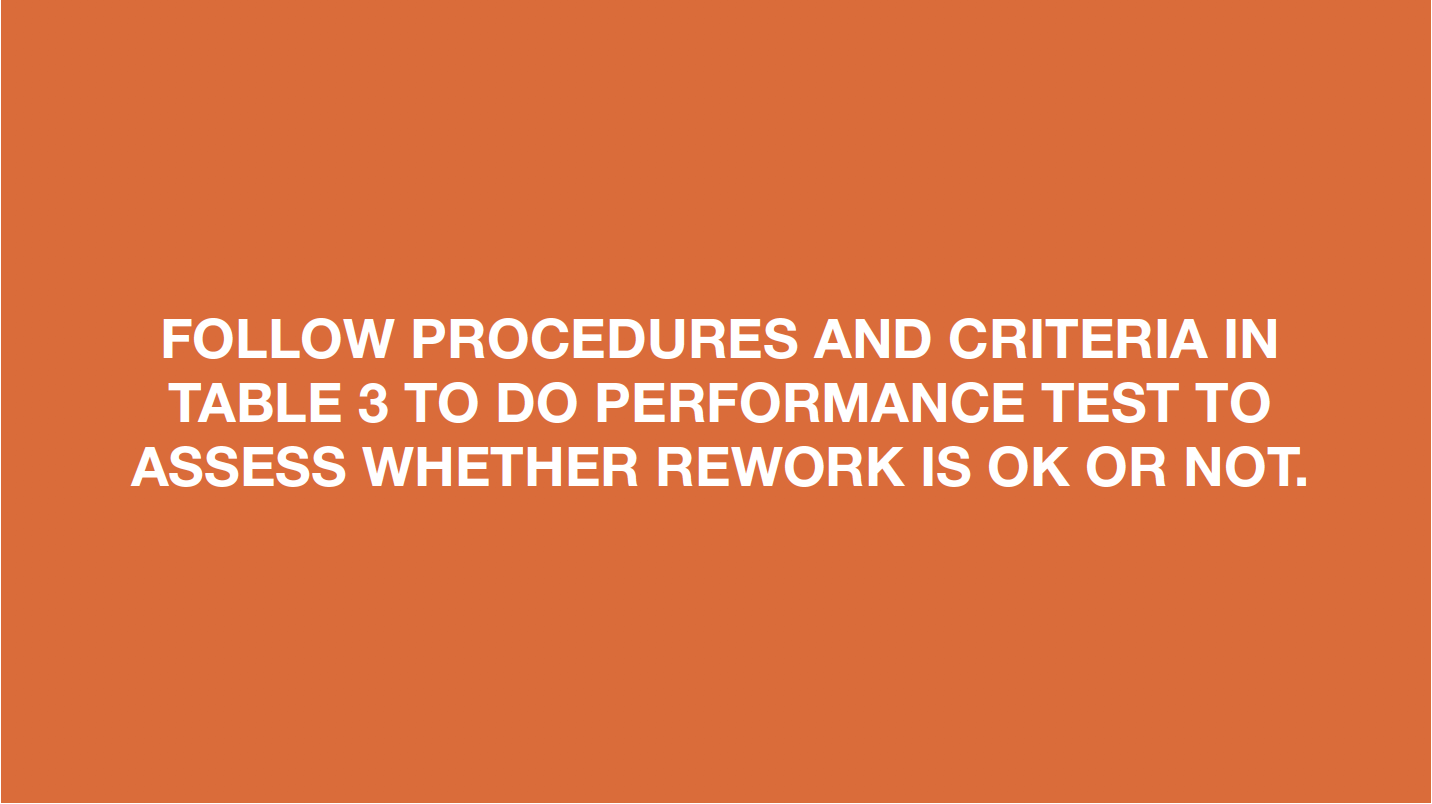

CHECK AND TEST 2

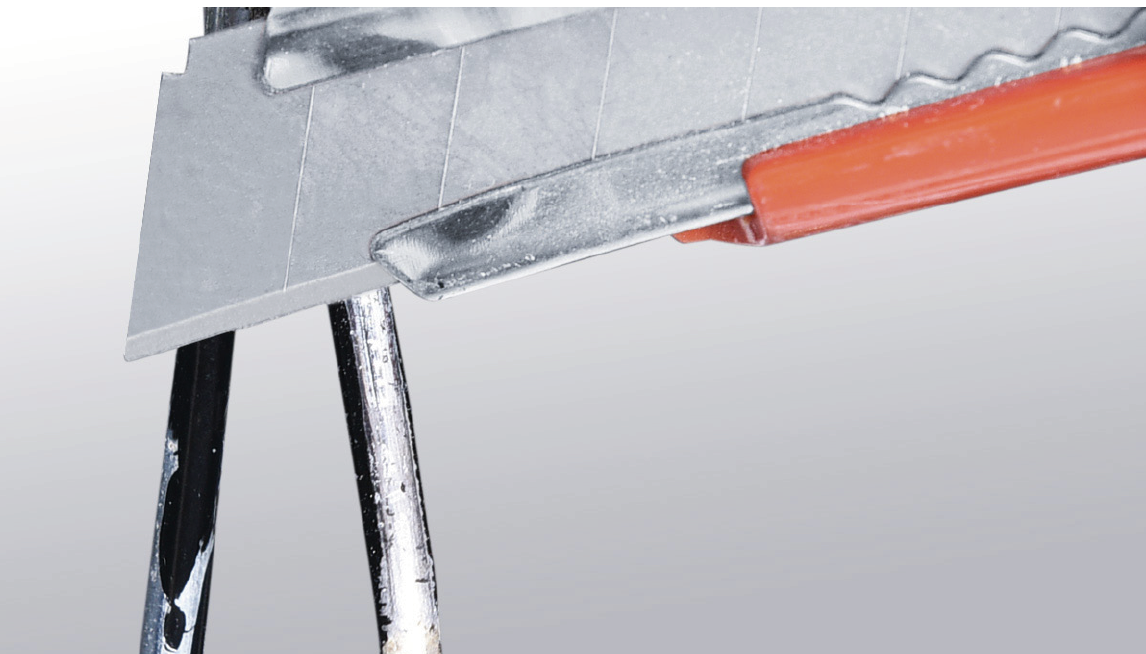

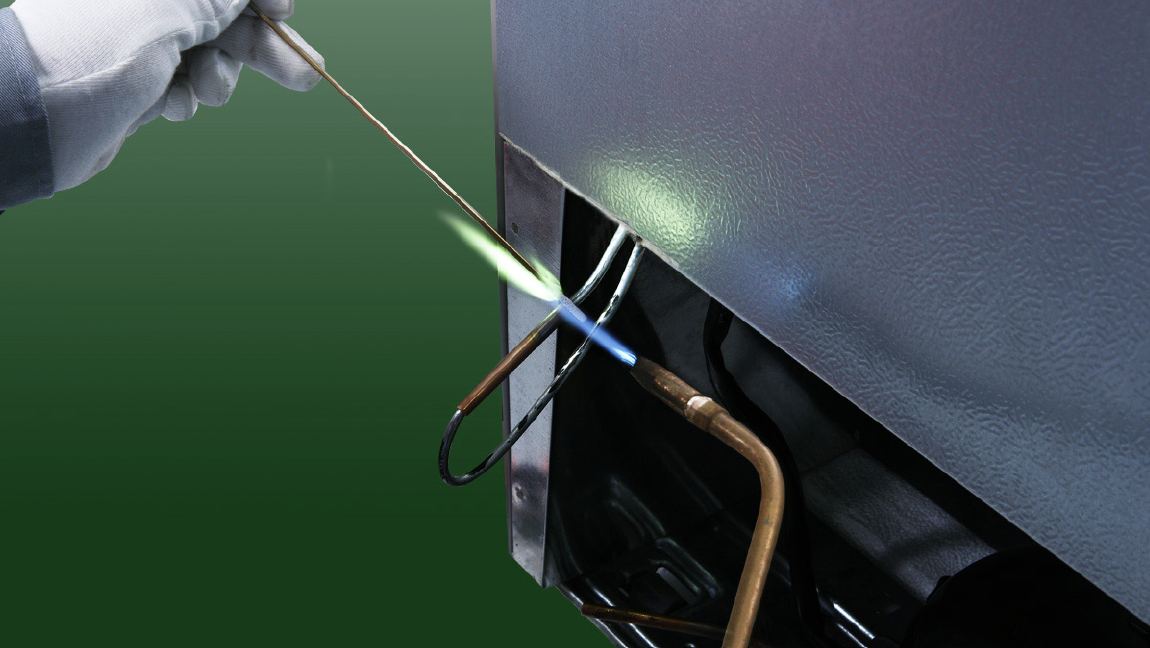

Step 1

Braze the joints of

suction and exhaust

pipes.

Step 2

1) Melt brazing material

with flame and pull

out processing tube

using a pair of pliers.

2) Re-braze a copper

tube onto compressor

processing tube.

To get more details on

brazing requirements,

please go to Annex B1

Step 3

Replace the filter.

1) Clean paint from

brazed joint of

drying-filter.

2) Cut off drying-filter.

3) Cut off capillary and

shake to remove the

cut end.

4) Braze on a new

drying-filter.

Step 4

Add quick connectoronto processing pipe of

drying-filter.

Step 5

Inject nitrogen (1.57Mpa)through quick connector

into pipe for at least 3

min to blow remaining

refrigerant away.

1) First, cut off end

closed to exhaust end

(A in below picture).

2) Then, cut off the end

closed to suction end.

DIAGNOSIS 2

PROCEDURE 2

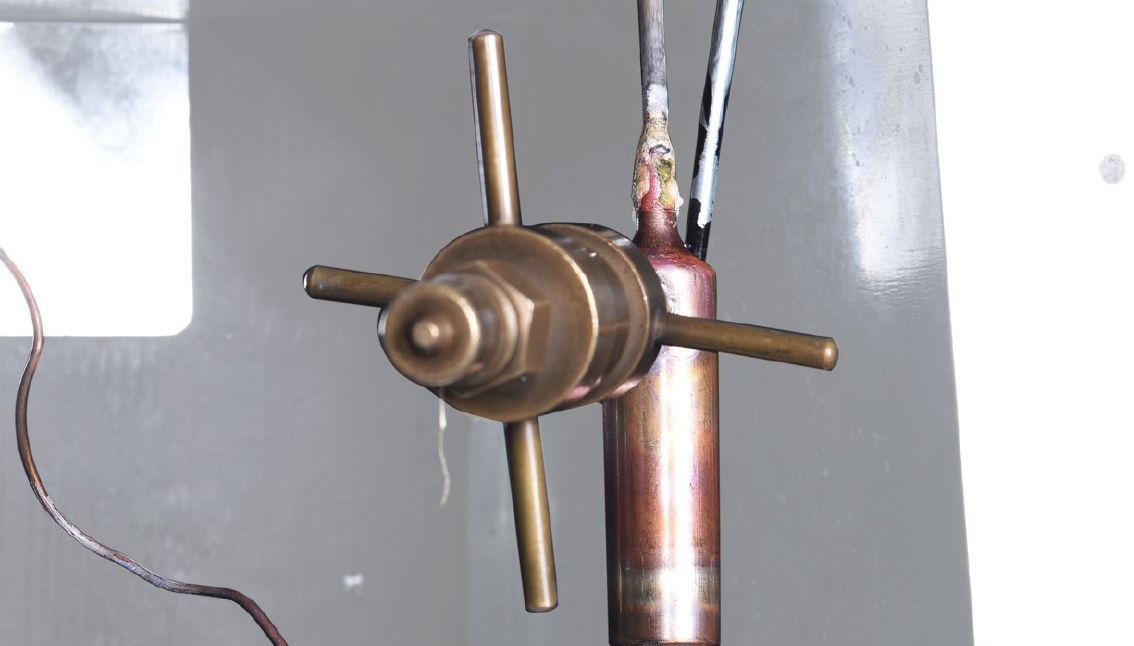

Step 1

Use a larger copper tube to connect 2 ends of brazed joint.

Step 2

Braze the 2 ends. Click below link to get more details for brazing requirements, go to Annex B1

NOTE

PROCEDURE 3

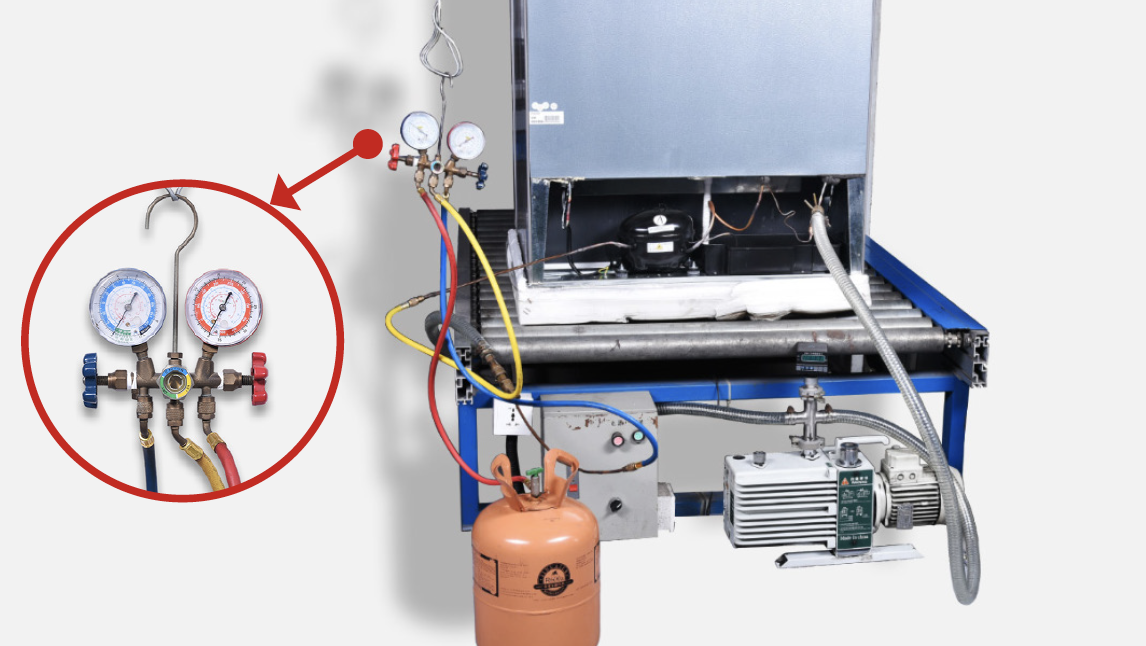

Step 1

Perform a leakage teston all re-brazed joints.

Step 2

Click below link to get more details for vocuuming and gas-charging requirements, go to Annex B2

Step 3

Block processing pipe

twice with locking pliers.

Step 4

Leave locking pliers onthe second block and

cut off the rest of the

pipe by shaking.

Step 5

Braze the ends andremove the pliers.

DIAGNOSIS 2