PROCEDURE 1

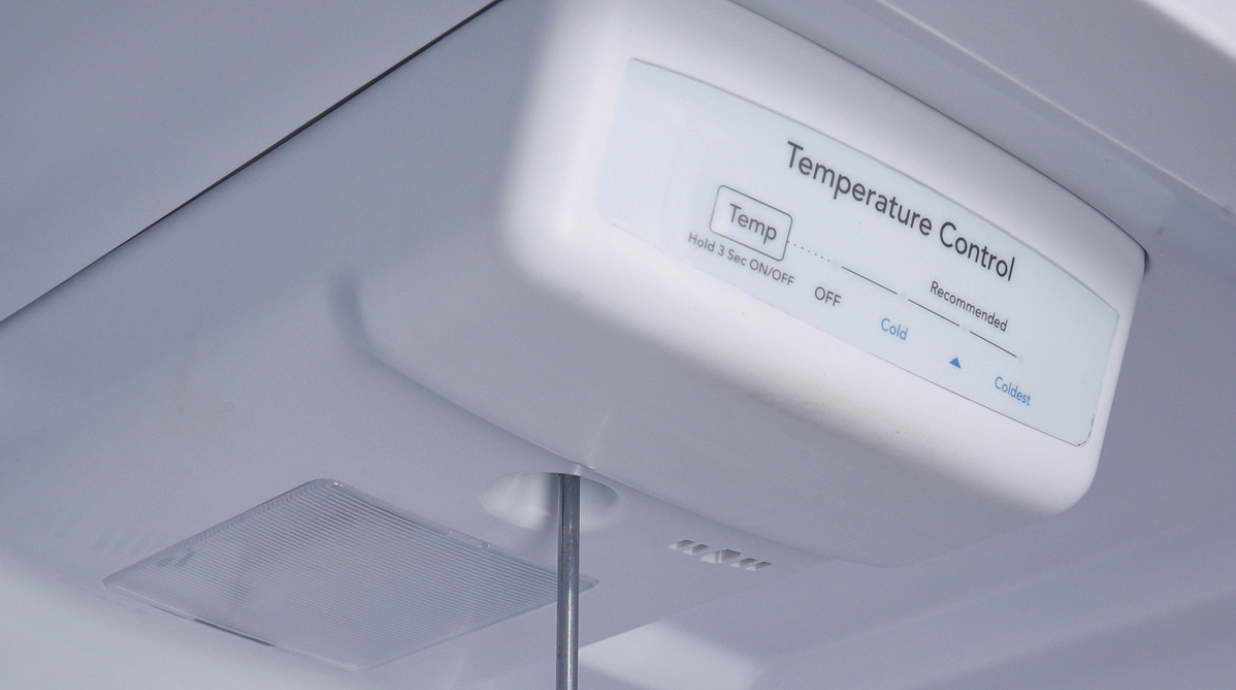

Step 1

Unscrew the screw of fridge air duct.

Step 2

Remove the LED lamp cover and the screw.

Step 3

Remove the air duct.

Step 4

Unplug the electrical wires.

Step 5

Disconnect the terminal of potentiometer.

Step 6

Remove the UI film.

Step 7

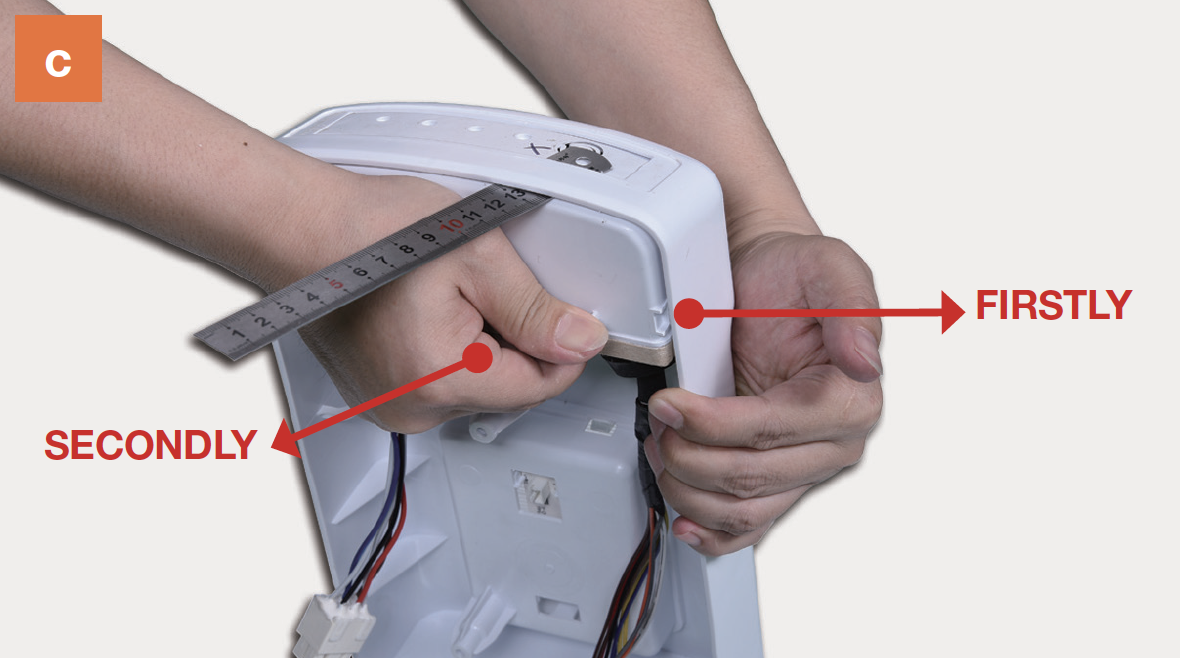

Remove PCB box from air duct.a) Use 2 mm slot screw driver to create a gap in front side.

b) Insert a steel ruler to even the gap.

c) Pull the PCB box out.

Step 8

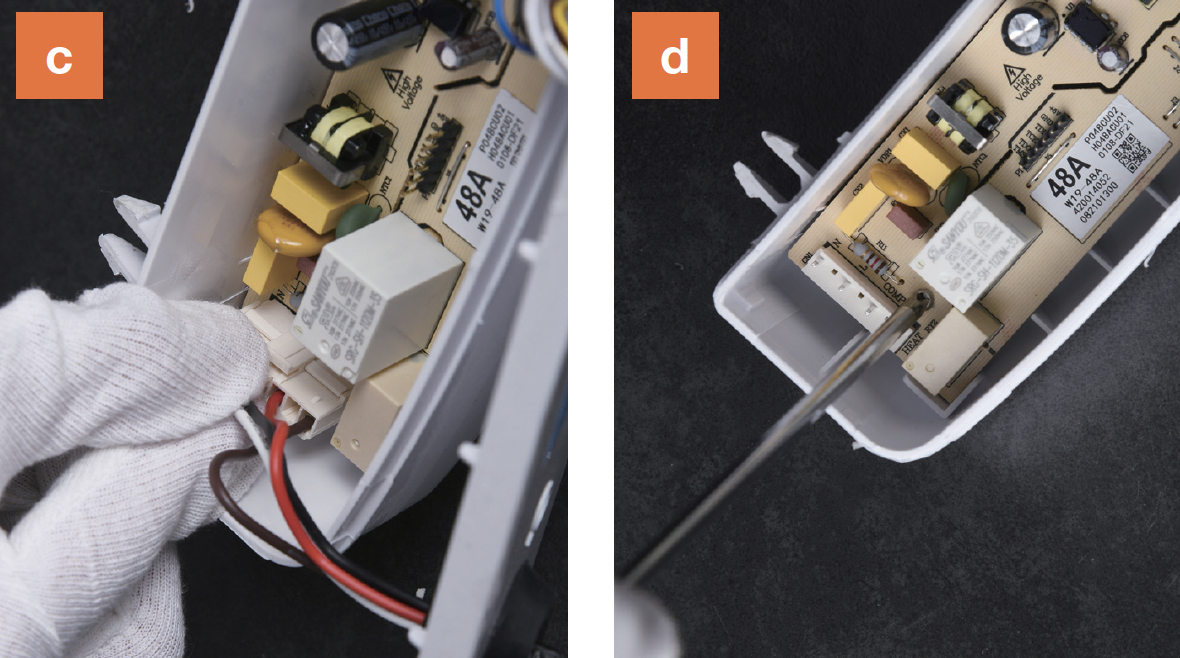

Disassemble PCB box.a)Prize off the buckle;

b) Remove the cover;

c) Disconnect the terminals;

d) Unscrew and remove the PCB;

CHECK AND TEST 2

Step 1

Reconenct all wires for fan, LED, heater, sensor, compressor etc..

Step 2

The terminal is not pushed into final

position: insert again to make sure that

connections are good.

Step 3

Check if terminal is filled with foam: use tweezers to pick foam out andinsert the terminal into position again.

DIAGNOSIS 1

Step 2

Supply power from terminal in PCB area.

DIAGNOSIS 1

PROCEDURE 2

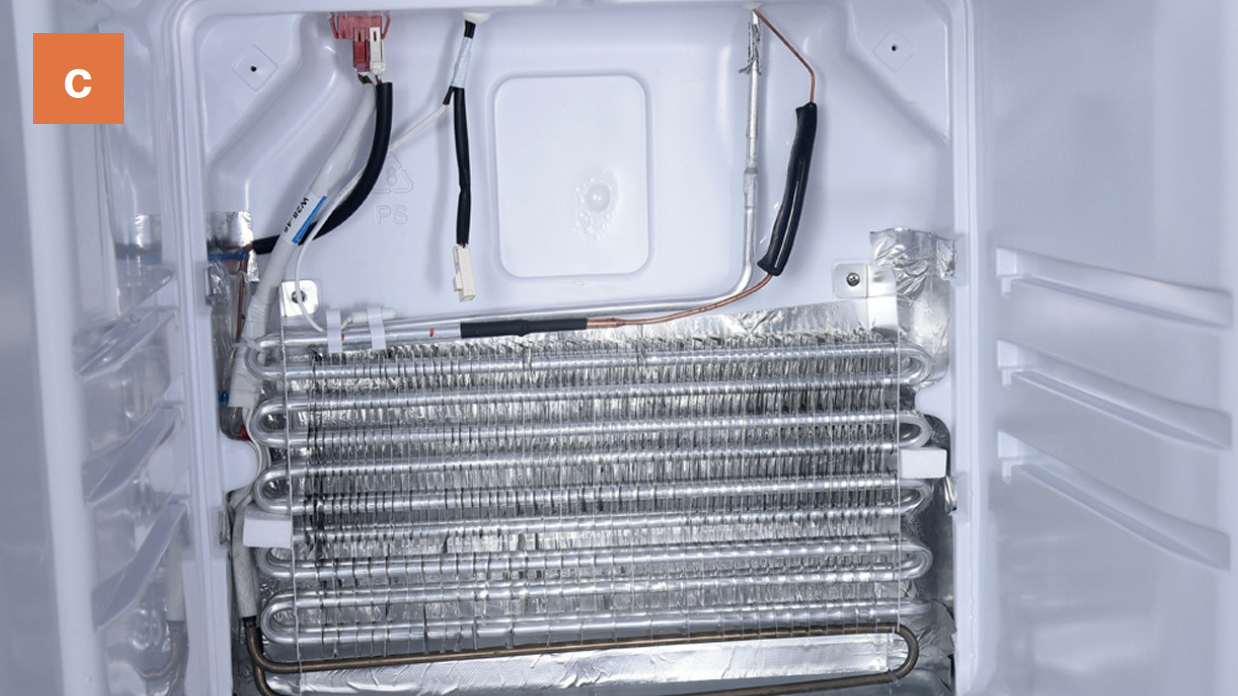

Step 1

Remove freezer shelf.

Step 2

Lever 2 screw covers off.

Step 3

Unscrew 2 screws.

Step 4

Remove air duct:

a. Hold the decorative cover of air duct;

Pull air duct out;

PROCEDURE 3

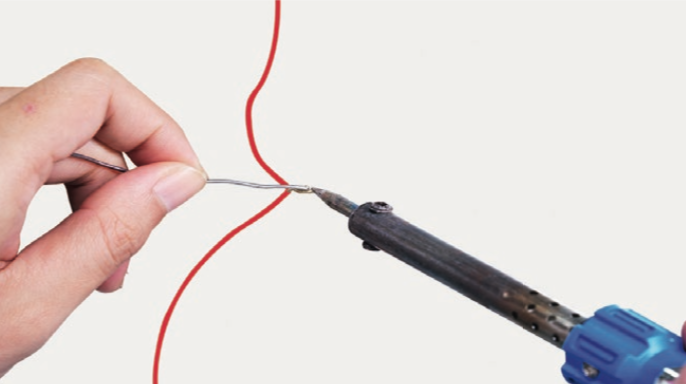

Step 1

Cut wire off from broken

area.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and connect them.

Step 5

Cover connection with electrical tape.

CHECK AND TEST 4

Step 1

Set output of transformer

to DC 12V to test fan

from the terminal behind

freezer air duct.

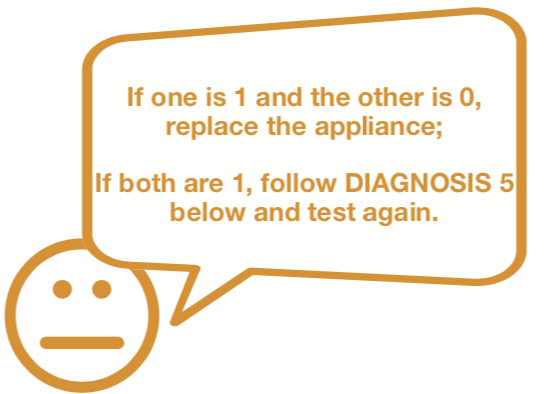

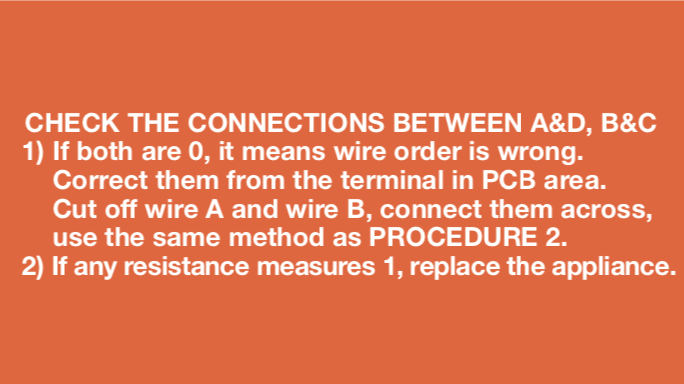

DIAGNOSIS 5

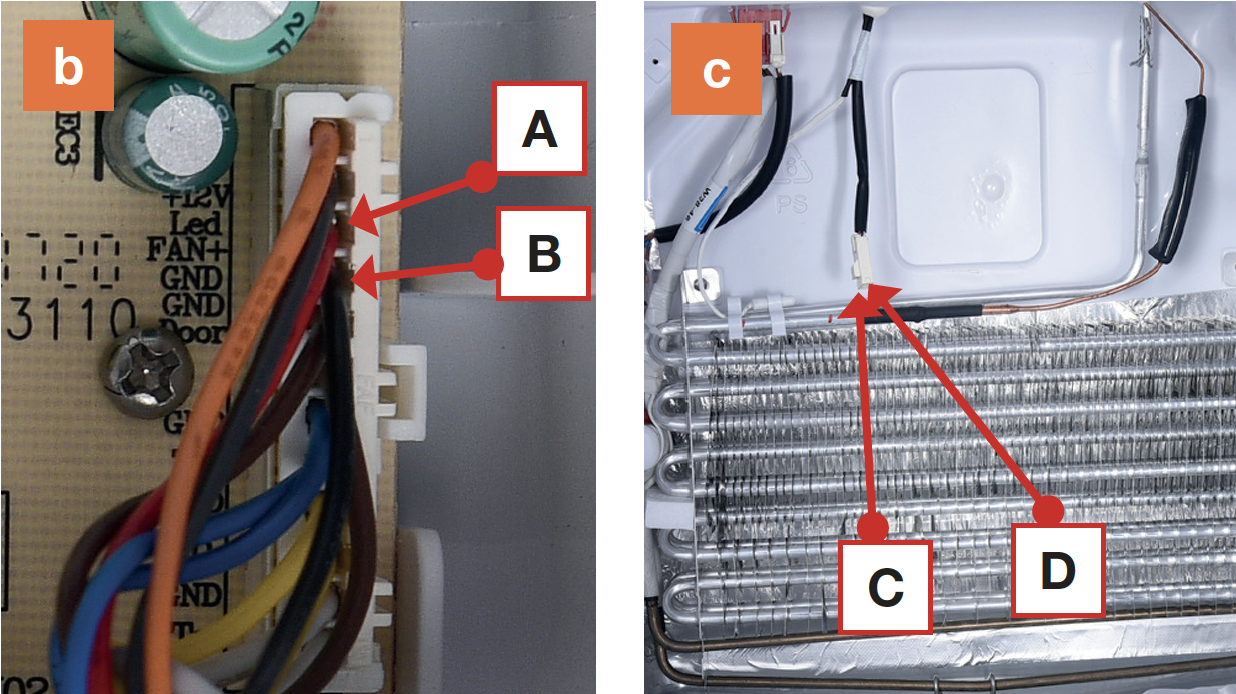

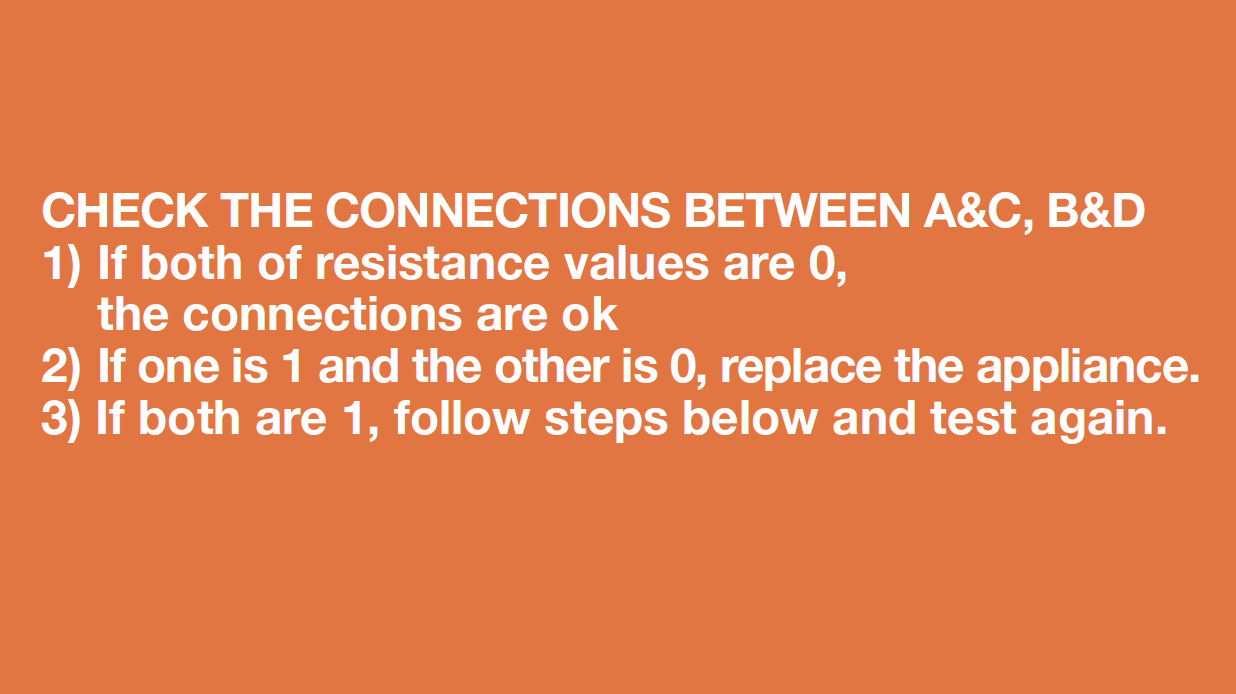

CHECK AND TEST 5

Step 1

Check if the terminal is filled with foam.If so, use tweezers to remove foam.

Step 2

Check if wire order in foam is right or not:a. Set multimeter to resistance gear;

Step 3

b. Put detector into one end of wires in PCBarea.

c. Put another detector into end of wires

behind air duct.

DIAGNOSIS 6

DIAGNOSIS 7

Tip 1

Firstly insert the air duct into the slot at the

bottom.

Tip 2

When reinstalling air duct, move wires out

of the way to prevent crushing by air duct.

Tip 3

After pushing air duct back into position, you

should hear a clicking sound. If there is no

click, please repeatagain.

CHECK AND TEST 6

Step 1

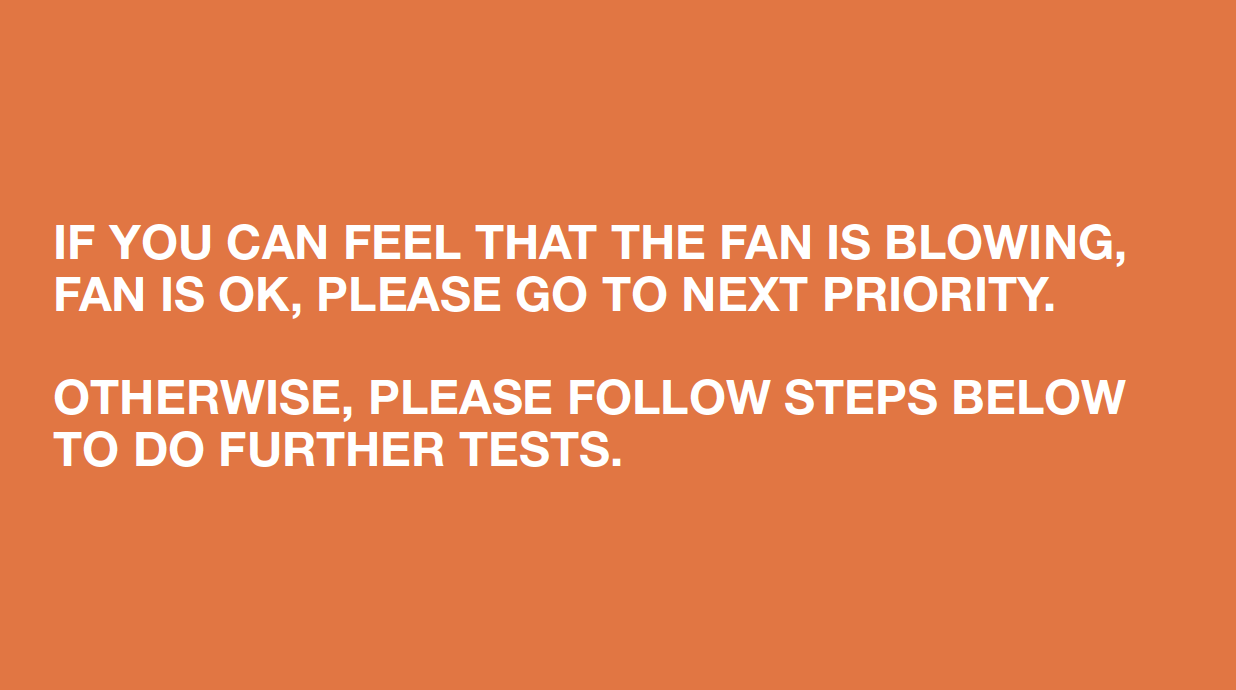

Open the freezer and put your hand to freezer to feel if the fan is running.

DIAGNOSIS 8