CHECK AND TEST 1

Step 1

Cut off capillary to discharge refrigerant.Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhaust pipe.

Step 4

Power up the

compressor and feel the

exhaust pressure from

the exhaust pipe with a

piece of paper.

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

Braze the joints of suction and exhaust pipes.

Step 2

Melt brazing material with flame and pull out processing pipe with pliers.

Step 3

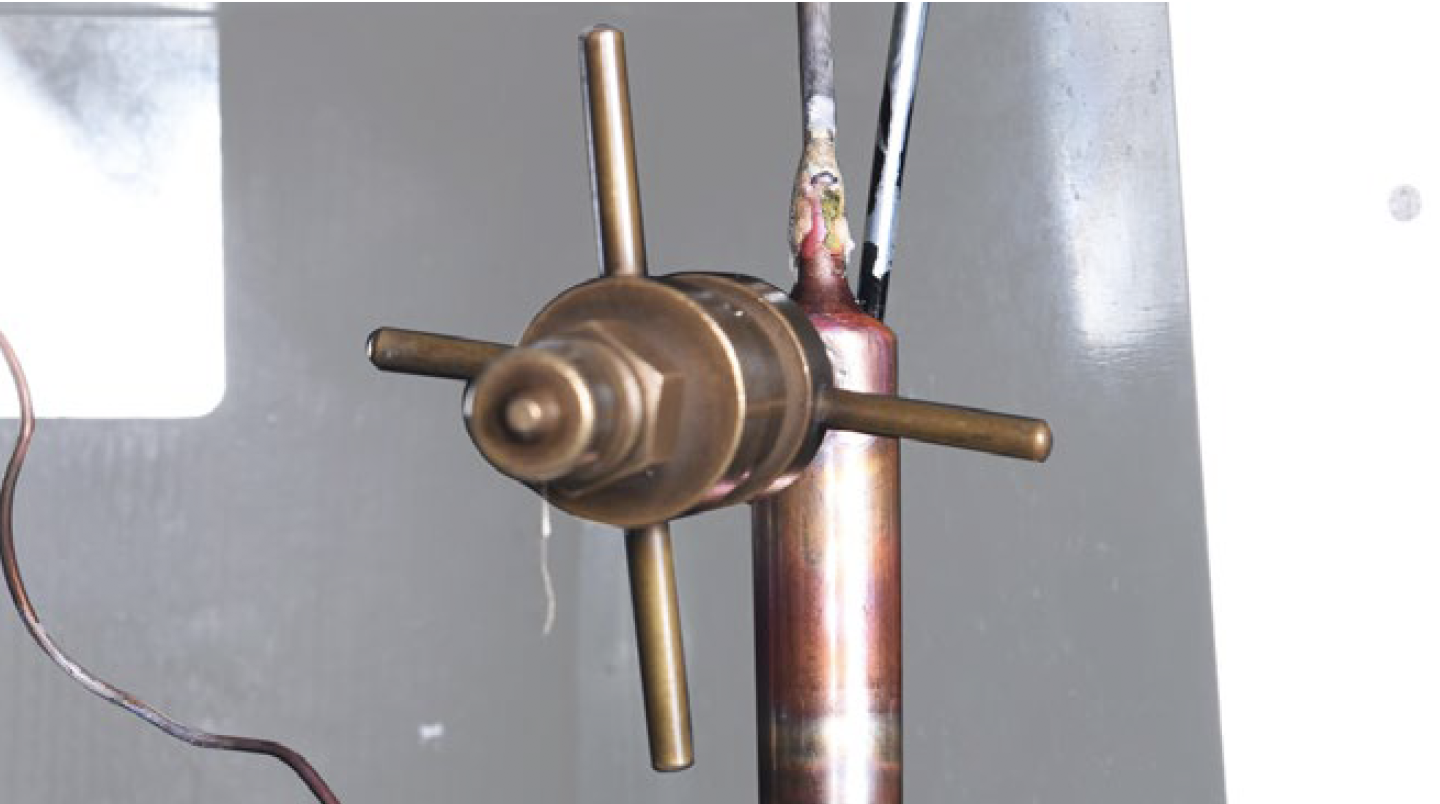

Re-braze a copper tube onto processing pipe of compressor.

Please find more details of brazing requirements

NOTE

Step 4

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 5

Check to see if gas pressure from capillary is normal or not.

Note:

Measure the 2 ends of

cutting points

DIAGNOSIS 2

CHECK AND TEST 3

Step 1

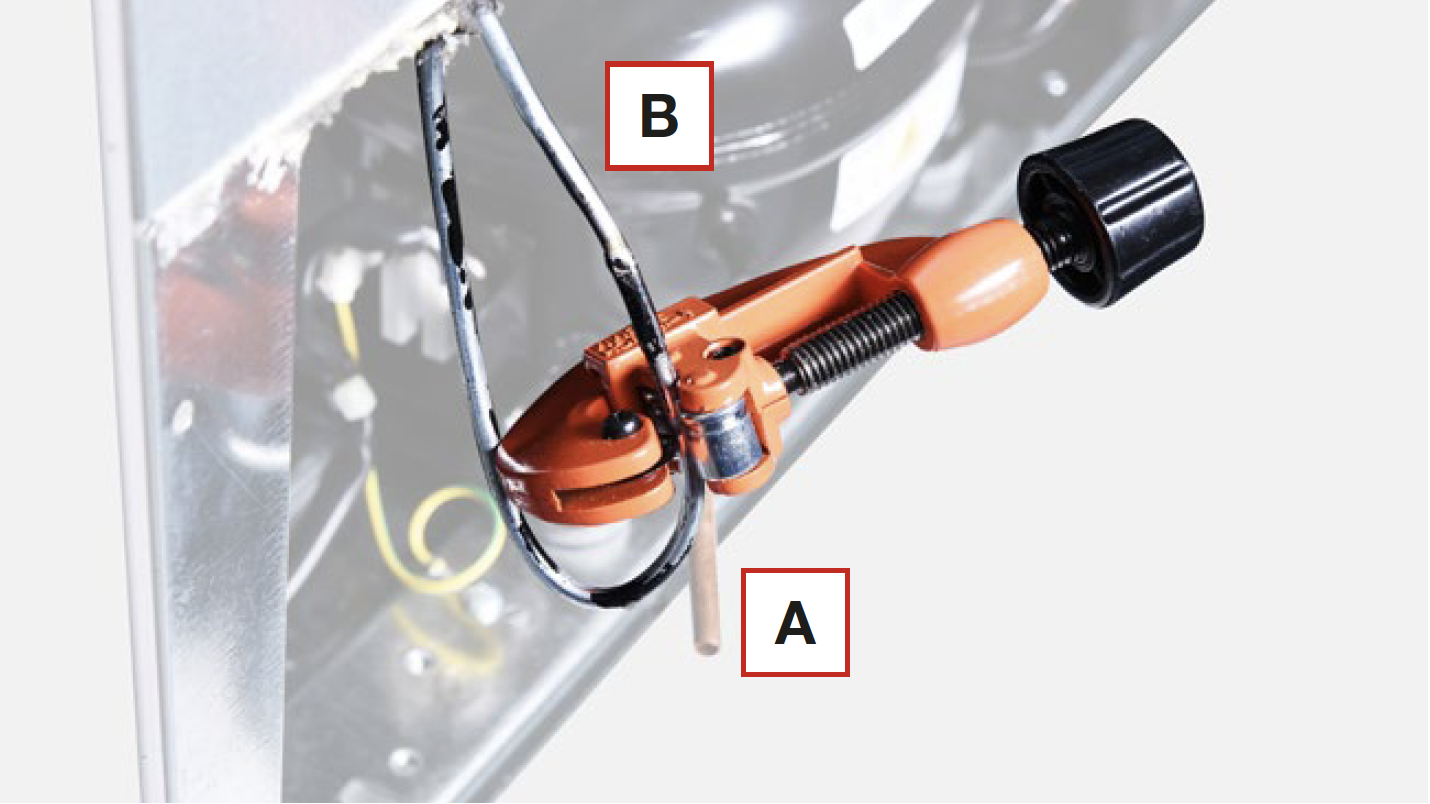

First, cut off end closed

to exhaust end (A in

below picture).

Step 2

Then, cut off the end closed to suction end.

DIAGNOSIS 3

PROCEDURE 1

Step 1

Use a larger copper tube to connect 2 ends of brazed joint.

Step 2

Braze the 2 ends.

PROCEDURE 2

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Cut off drying-filter.

Step 3

Braze on a new

drying-filter.

Step 4

Add quick connector onto processing pipe of drying-filter.

Step 5

Perform a leakage test on all re-brazed joints of drying-filter and compressor processing pipe.

Step 6

Vacuum and recharge.

Please get more details of vacuuming and gas- charging requirements

Step 7

Block processing pipe twice by locking pliers.

Step 8

Leave locked pliers attached to second block and shake to cut off the remaining pipe.

Step 9

Braze the ends and remove the pliers.

DIAGNOSIS 4