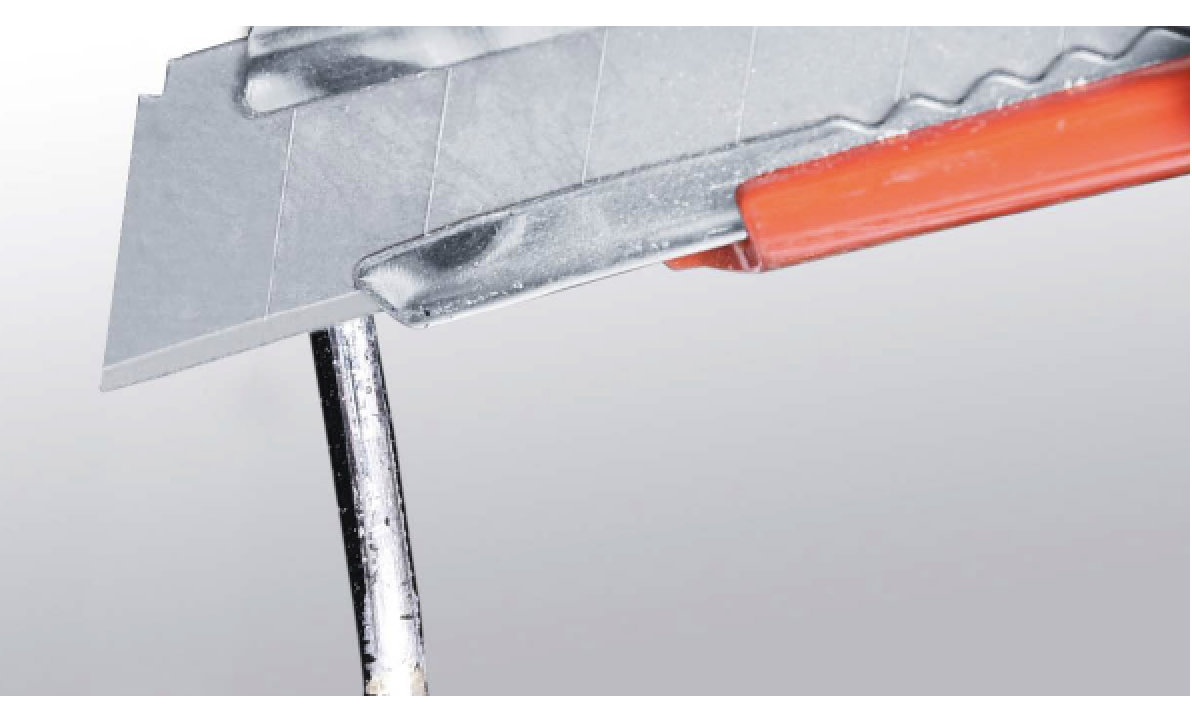

Step 1

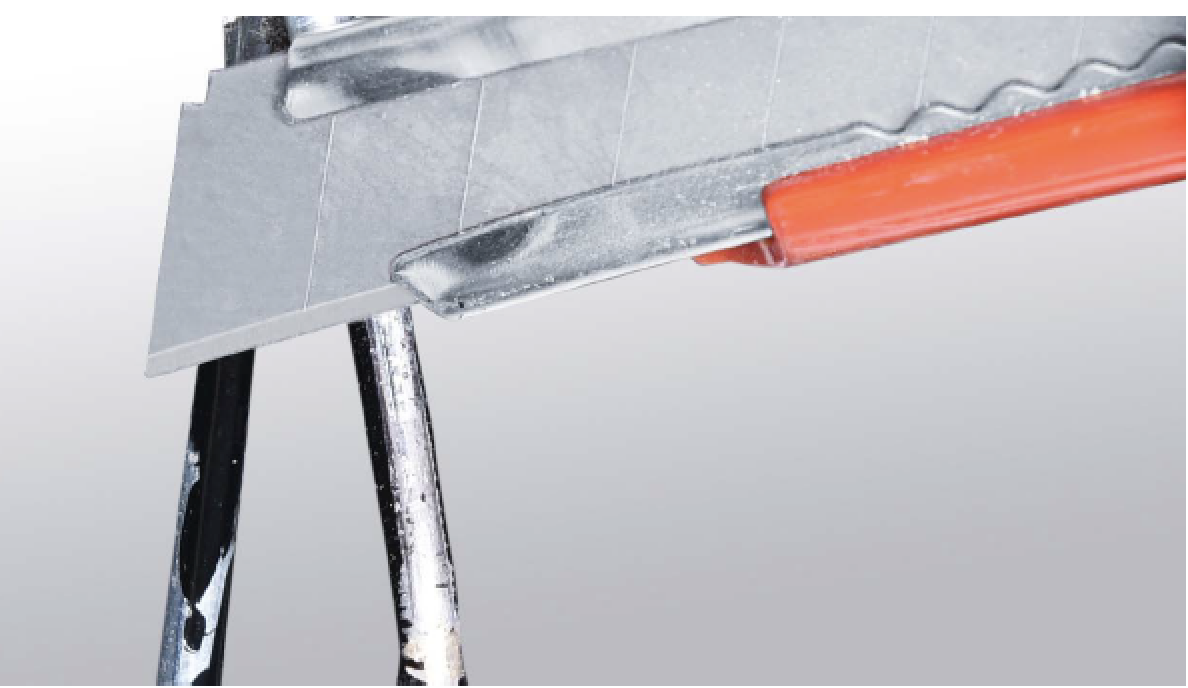

Discharge refrigerant: use pliers to cut off charging tube.

Step 2

Discharge all refrigerant toward the exhaust vent.

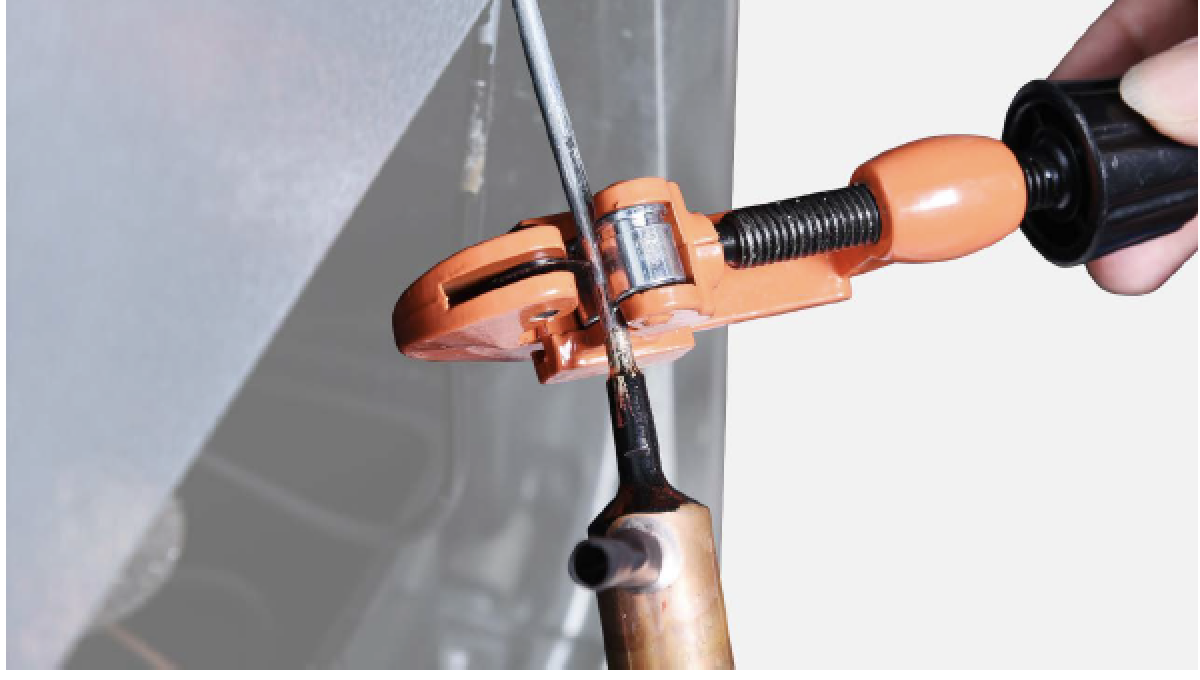

Step 3

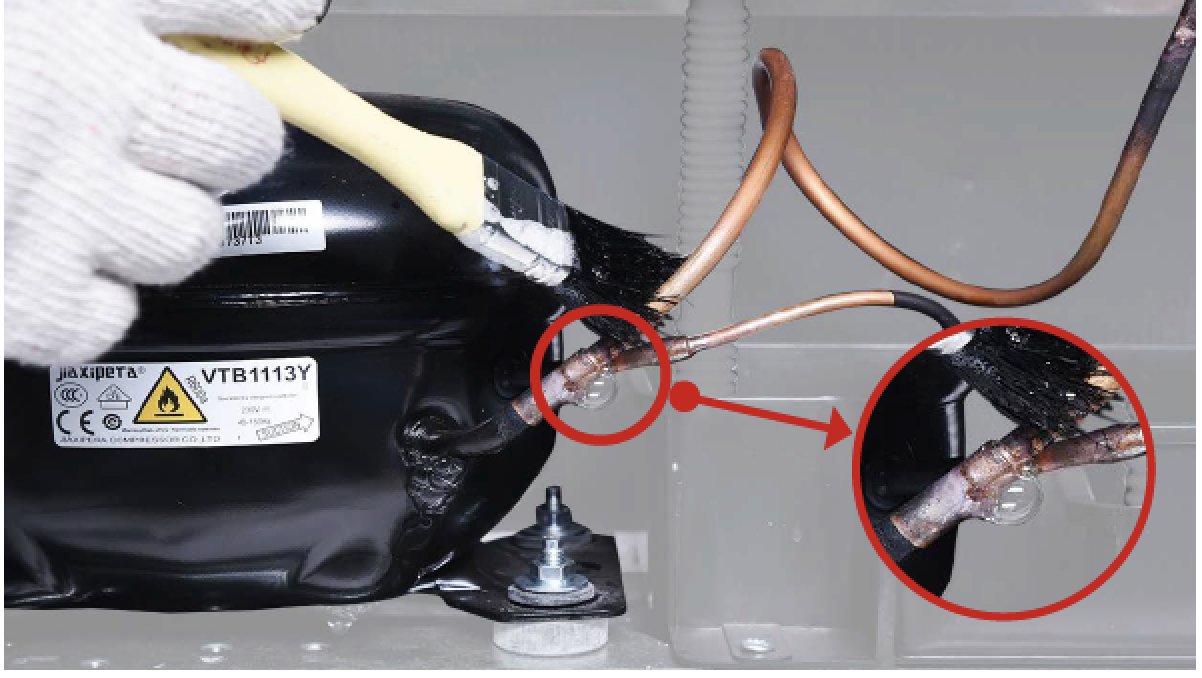

Melt brazing material with flame and pull processing tube out using a pair of pliers.

Step 4

Re-braze a copper tube onto processing tube of compressor.To get more details on brazing requirements, please go to

NOTE

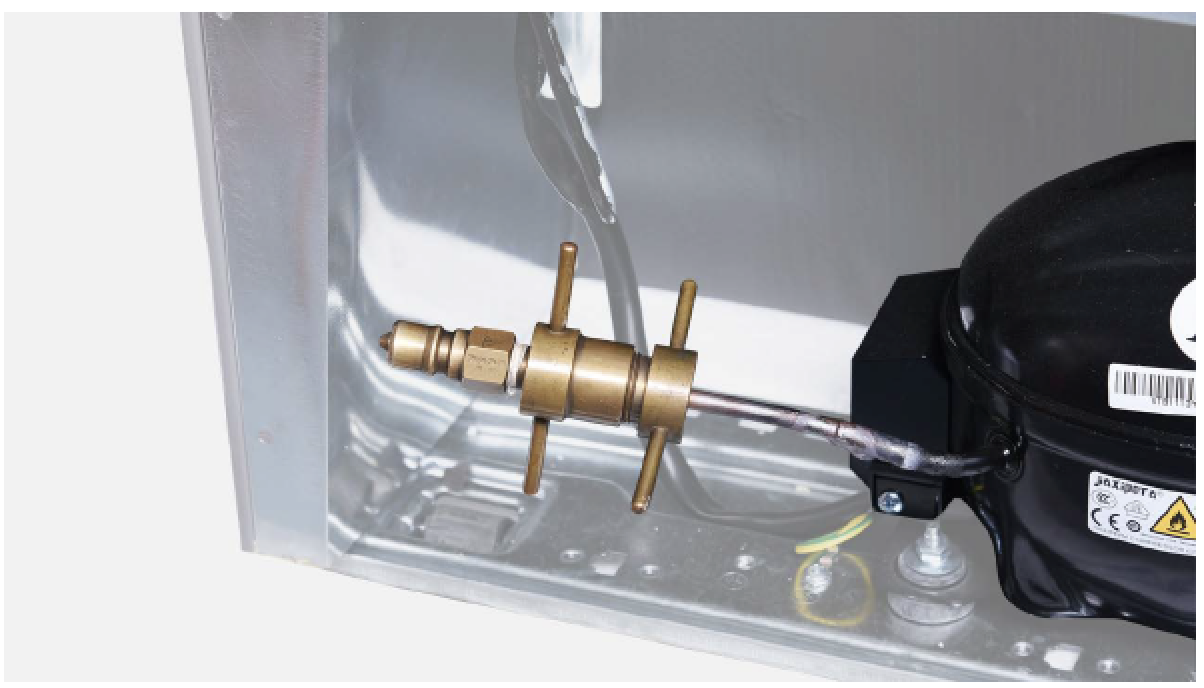

Step 5

Install quick connector onto re-brazed pipe.

Step 6

Inject nitrogen of 1.57Mpa through quick connector into pipe.

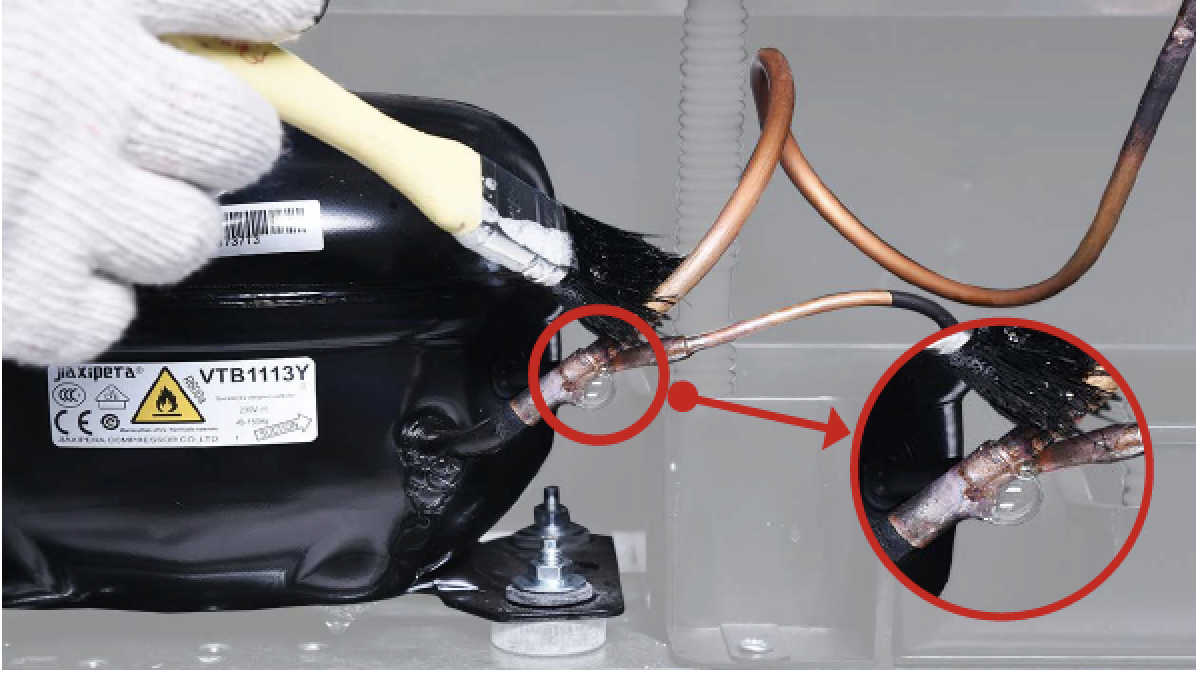

Step 7

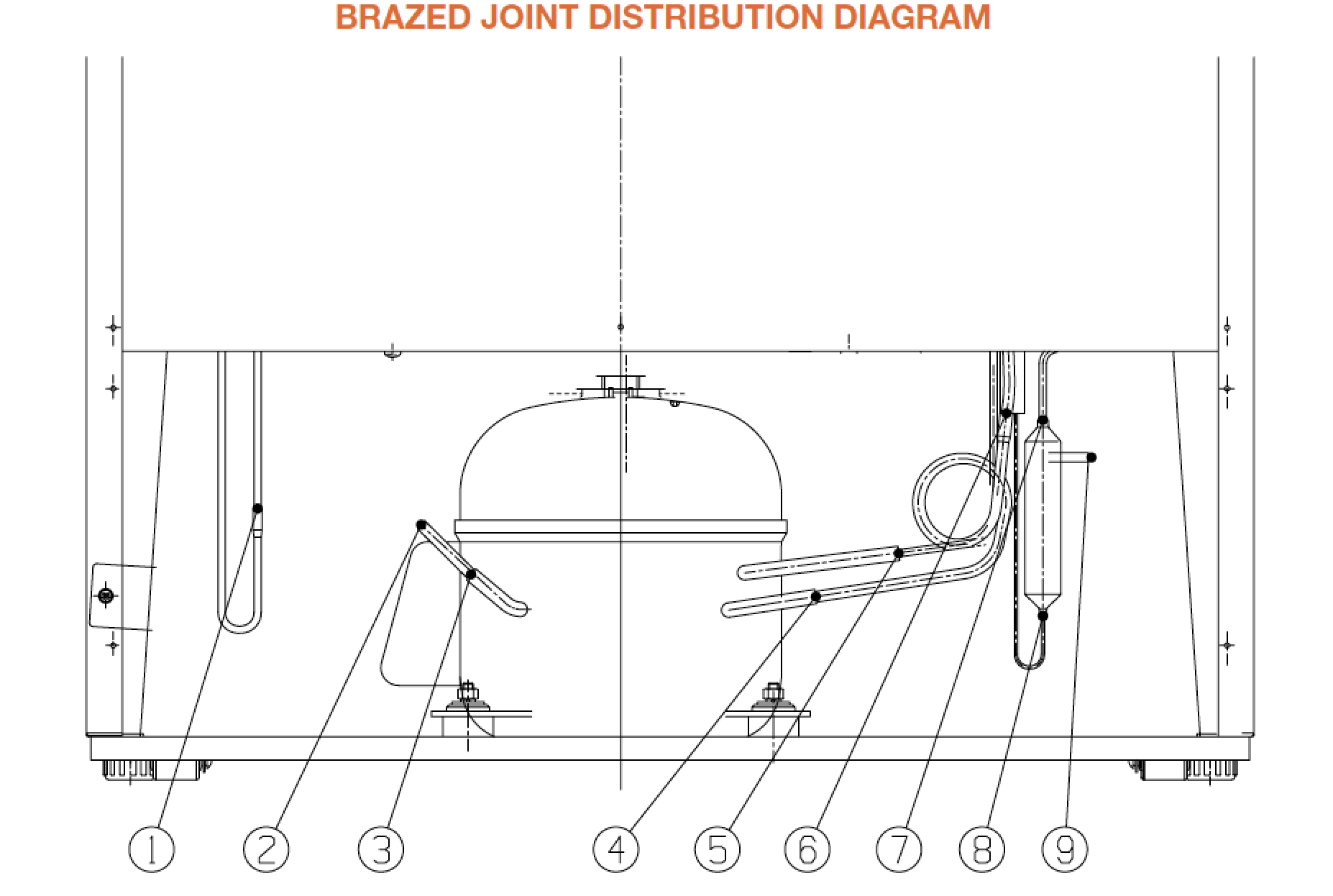

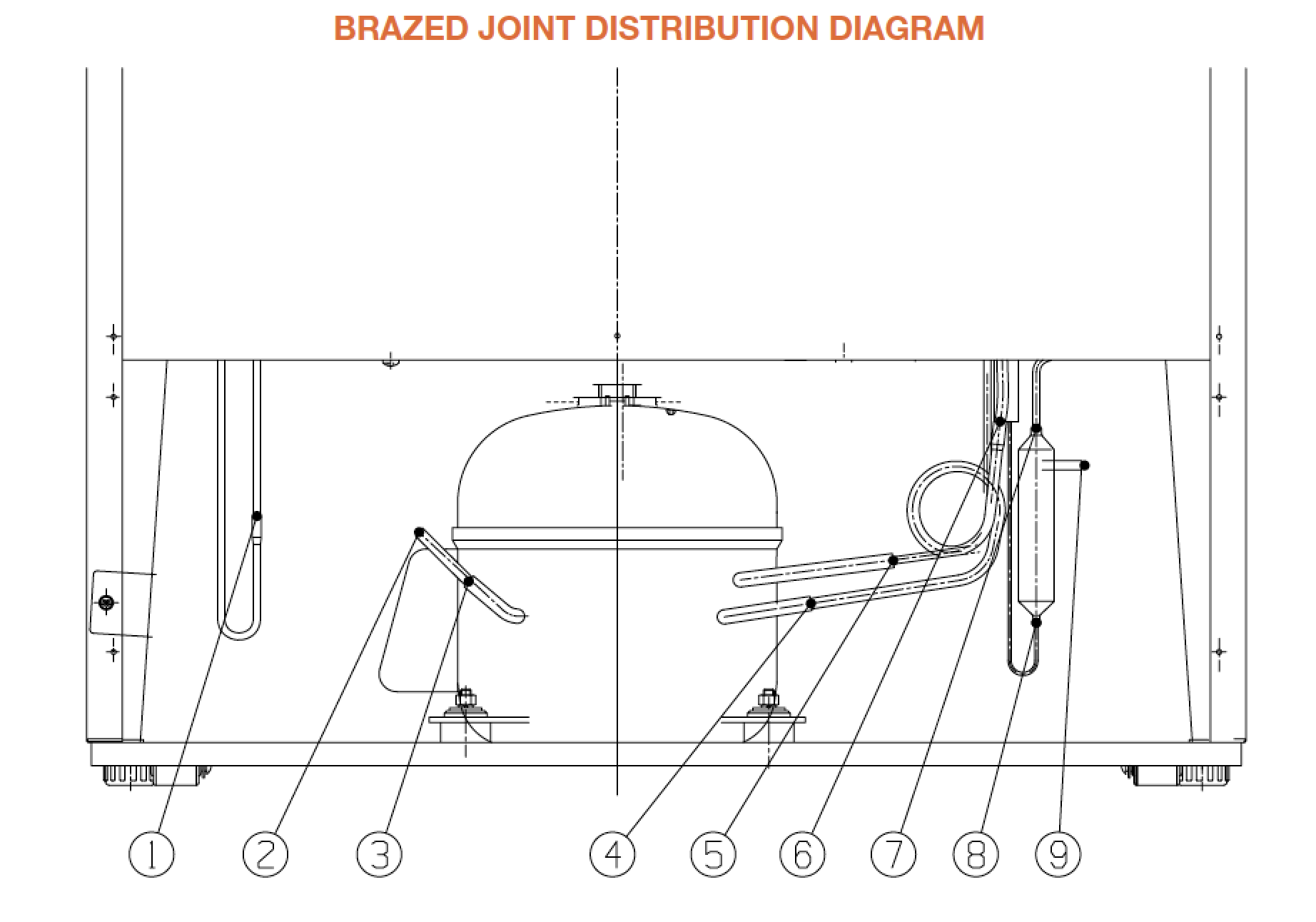

Please refer to drawing below to perform leakage test on brazed joints in compressorniche.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Clean paint off near leaking point.

Step 2

Cut off the pipe with leaking point.

Step 3

Use a bigger copper tube to connect 2 endsof brazed joint.

NOTE

Step 5

Inject nitrogen of 1.57Mpa through quick connector into pipe.

Step 6

Perform leakage test on brazed joints againin compressor niche to make sure re-brazing

was successful.

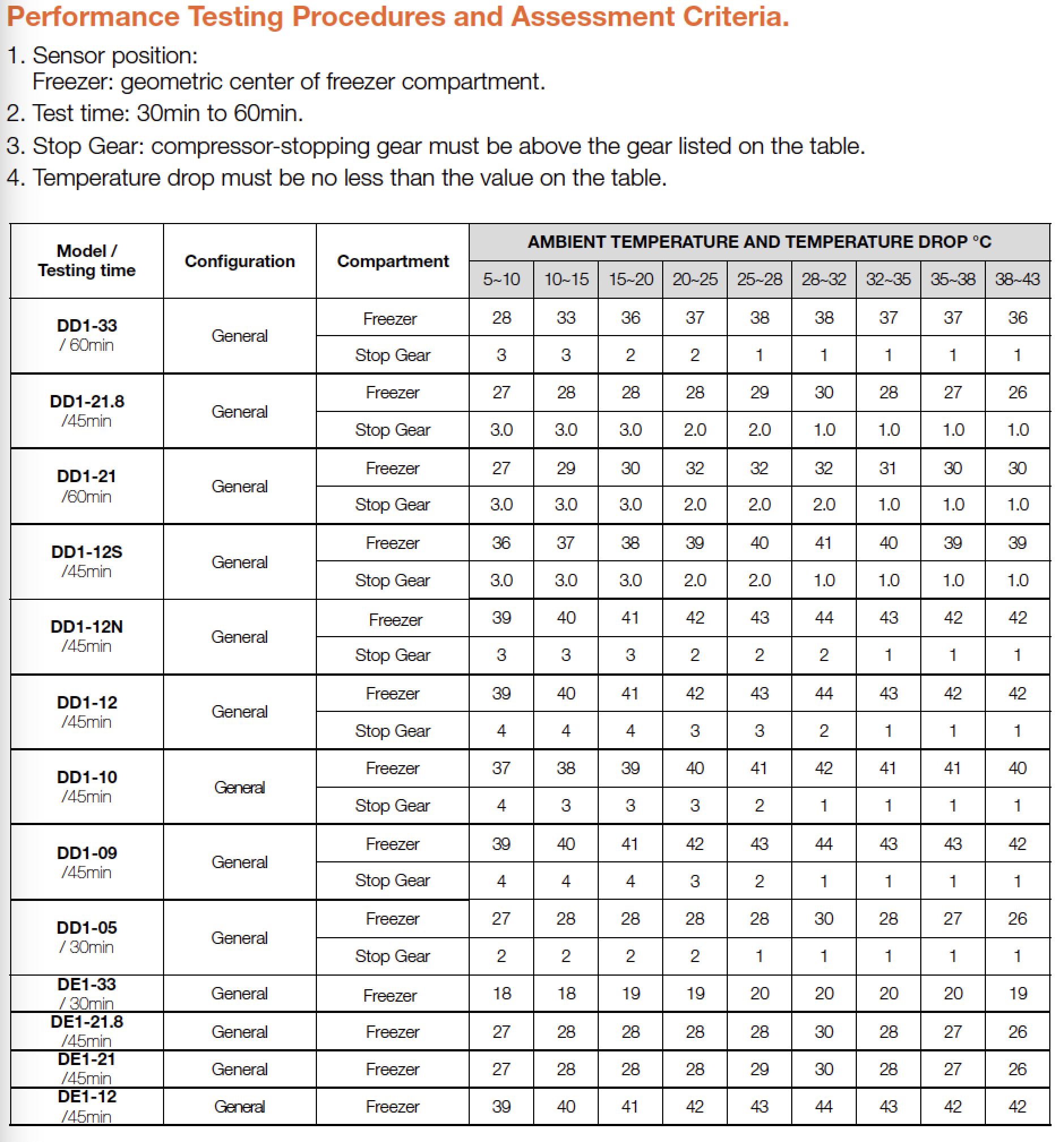

CHECK AND TEST 2

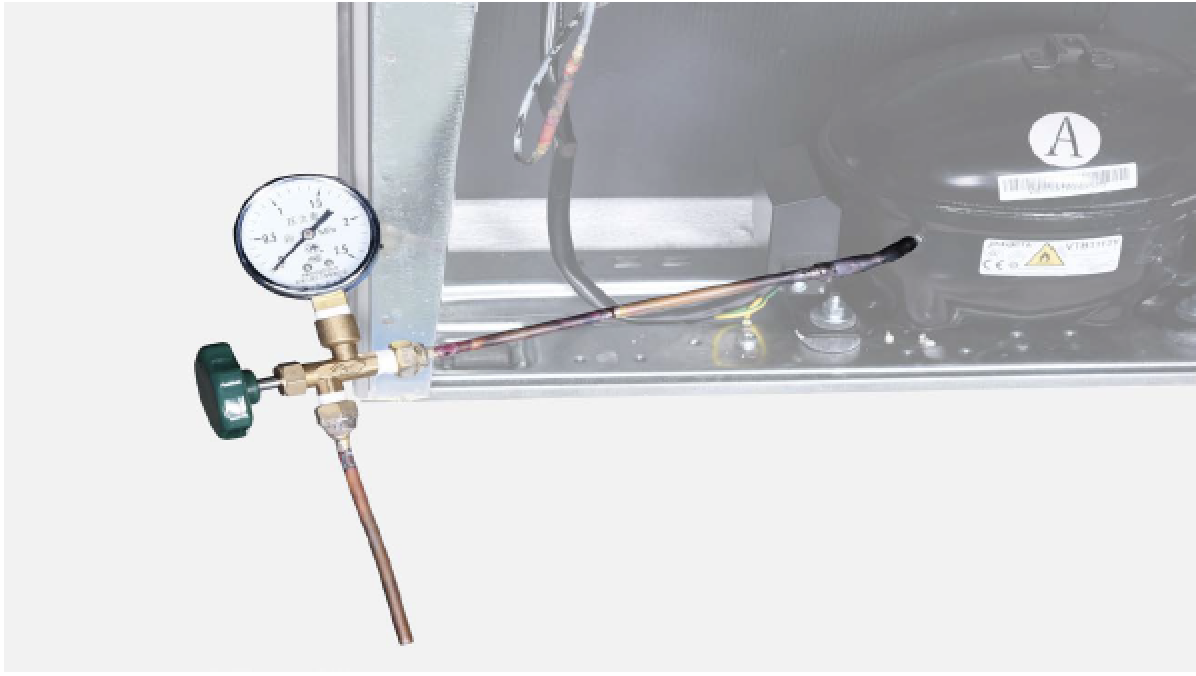

Step 1

Weld a piezometer onto processing tube ofcompressor.

Step 2

Charge nitrogen of 1.57Mpa through quickconnector into pipe.

Step 3

Do leakage test on brazing points andpiezometer.

DIAGNOSIS 2

DIAGNOSIS 1

Step 1

Clean paint off brazed joint of drying-filter

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and shake to remove the cutend.

Step 4

Weld on a new dryingfilter.

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe ofdrying-filter.

Step 7

Perform leakage test on brazed joints of dryingfilter and compressorprocessing pipe.

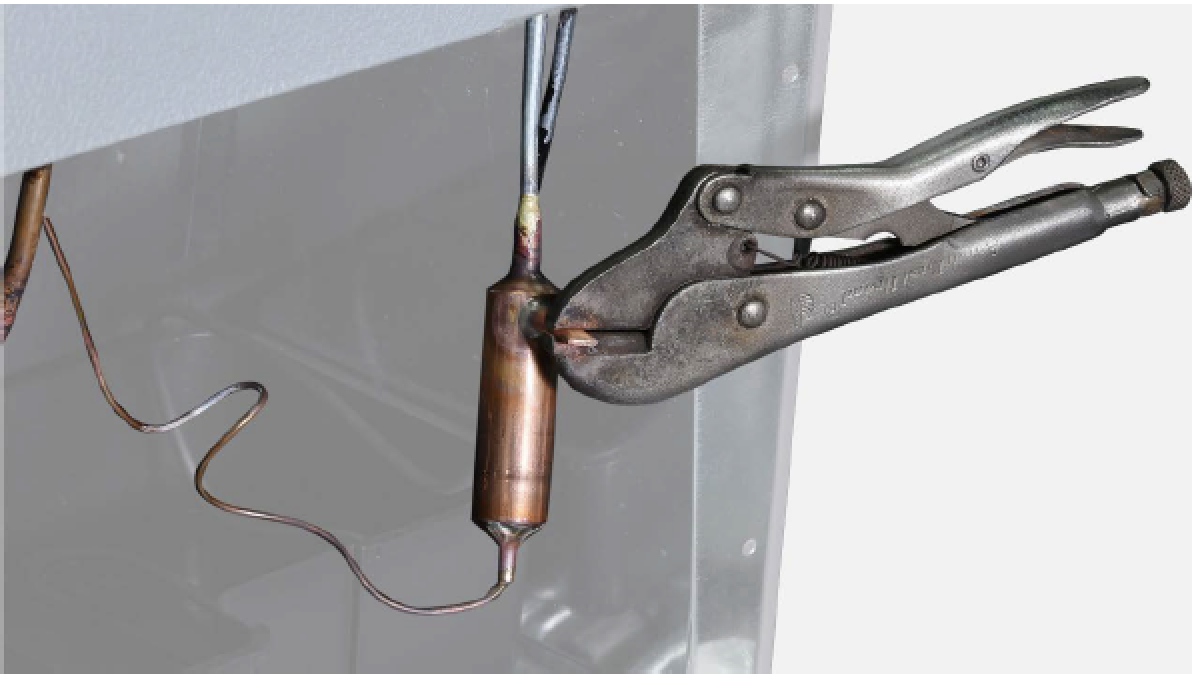

Step 9

Block processing pipe twice with locking pliers.

Step 10

Leave locking pliers on the second block andcut off the rest of the pipe by shaking.

Step 11

Weld the ends and remove the pliers.

CHECK AND TEST 3

DIAGNOSIS 3

Attention